8

8.1 Water Connection

Water Connections

To set or check the expansion vessel

charge pressure the lock-shield valve

between the unit and the vessel must

be closed. The drain cock fitted on the

base of the expansion vessel must be

open to allow any water in the vessel

to escape.

A suitable gauge should be used to

check the charge pressure. Generally

a Schrader ‘car type’ valve is fitted near

the top of the expansion vessel.

If the charge pressure is too high

it can be reduced by depressing

the centre of the Schrader valve or

by using a pressure gauge with an

integral air release valve. If the charge

pressure is too low a small increase

can be provided using a car foot pump

otherwise an oil free compressor or

nitrogen bottle is recommended.

Note! The expansion vessel charge

pressure should be set to 0.1 bar less

than the cold fill pressure. When the

correct pressure is set the Schrader

valve protective cap must be replaced.

Check the integrity of the pipe-work.

Ensure the lock-shield valve between

the unit and the expansion vessel is

open and the drain valve is closed.

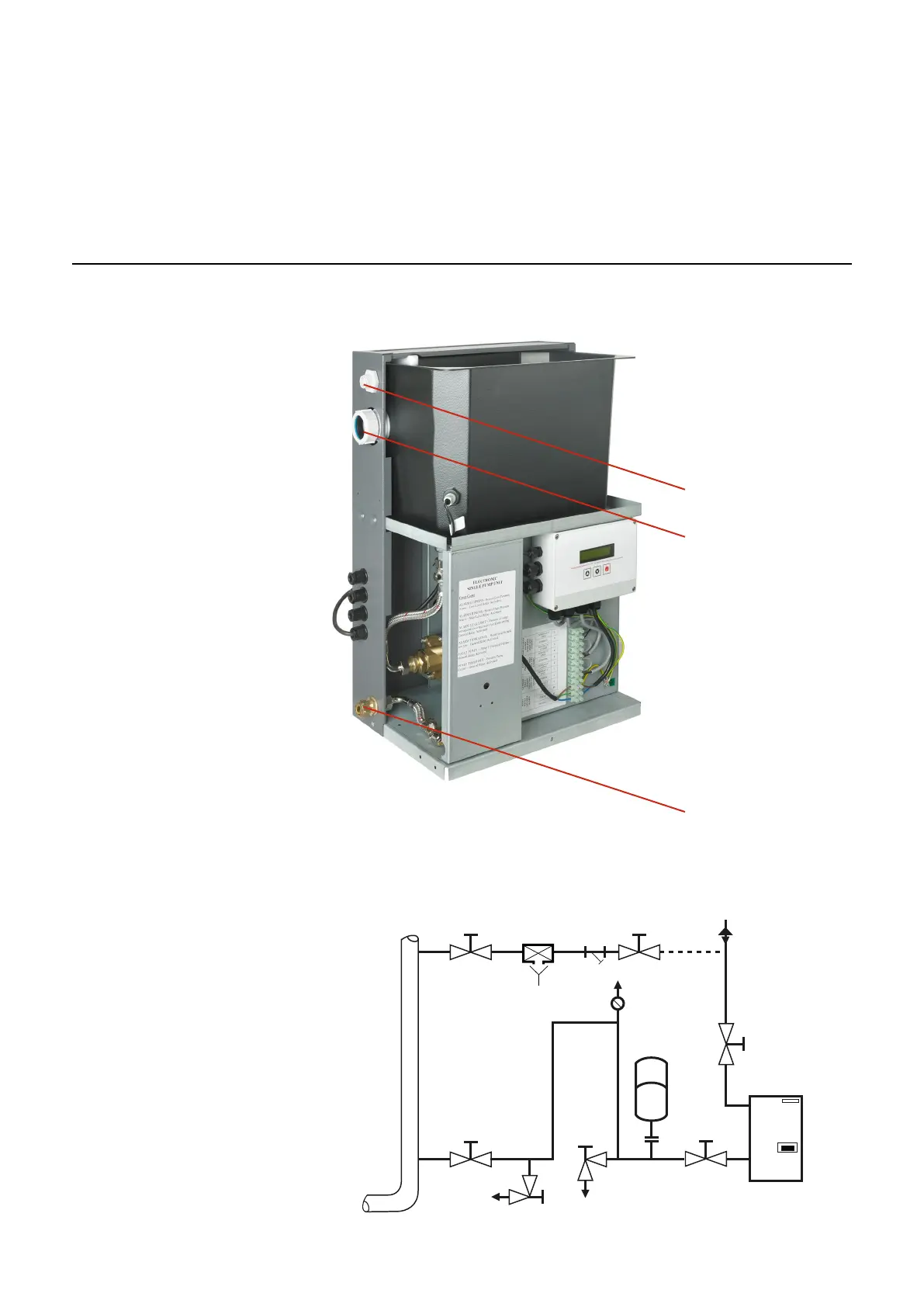

Lockshield

valve

Lockshield

valve

Drain

valve

Anti-gravity loop

drain valve

Pressurisation

unit

Lockshield

valve

Lockshield

valve

Lockshield

valve

Automatic

air vent

System expansion

vessel

(External to

pressurisation unit)

Mains water

supply

Strainer

System

return

header

RPZ

valve

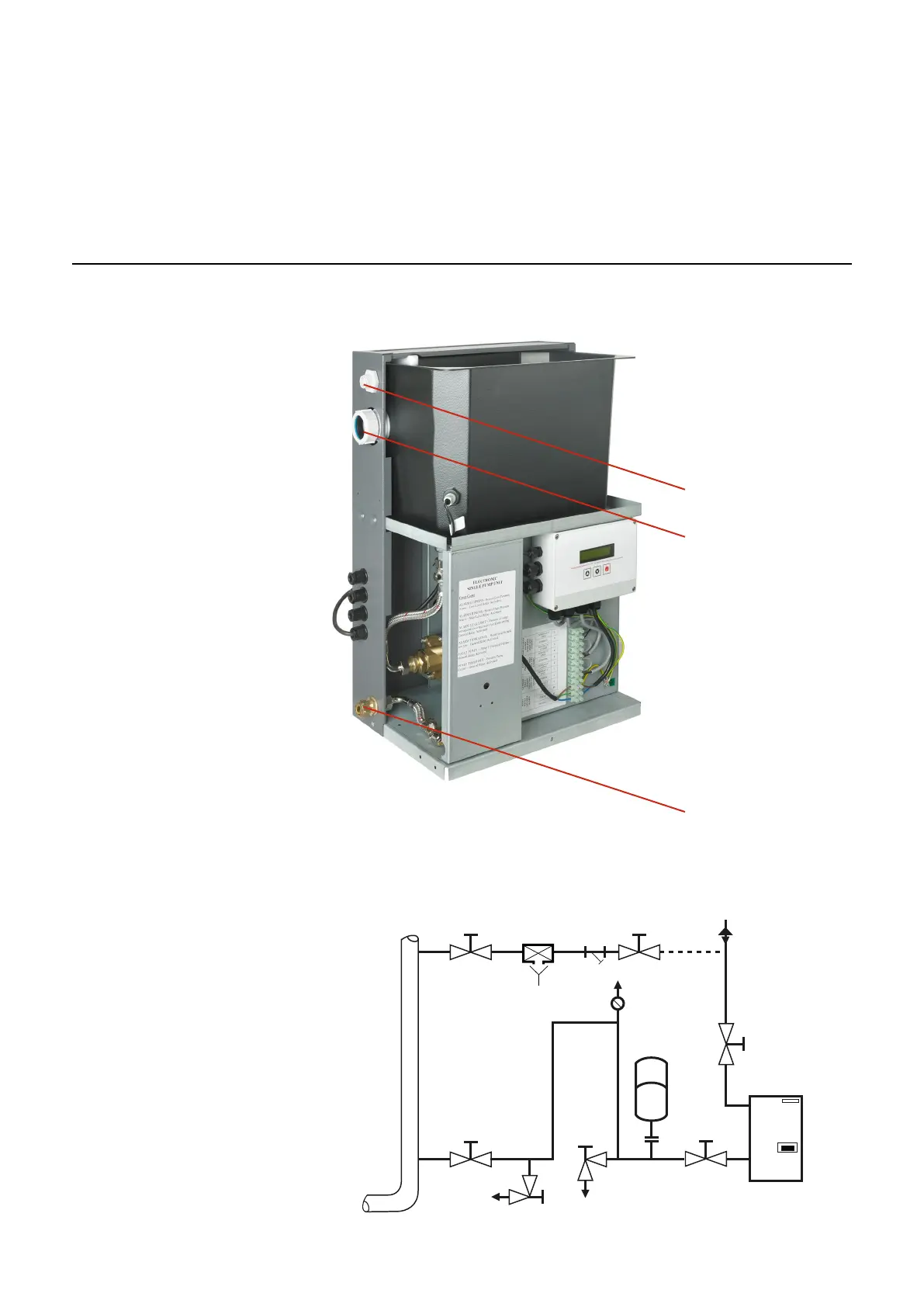

Figure 8.3 – Water connections

Figure 8.4 – System connections – clarity

15mm Mains cold

water supply (A)

32mm Plastic waste

outlet/overflow (B)

15mm System

connection (C)

Loading...

Loading...