Assembly

ConnectingEquipment,FillingSystem

Sip

honandcondensatedischarge

I

nsertsiphon(1)accordingtheFigure

totheleft.

Dis

mountcoverpanelingfromcon-

densingboiler.

Con

nectcondensatedischargeand

neutralizingdevice(accessory)to

siphon.

Note:

Thecondensatelinemustnotbefirmly

connectedtothesewerline.The

condensatemustbeabletofreelydrip

intoafunnel.

Fillingsystem

Con

nectwaterhosetoKFEvalve(2).

O

penallradiatorvalves.

Fil

lcoldsystemupto1bar.

M

onitorwaterquality.

Ven

tilatepump(loosenimpellerwith

screwdriverifnecessary).

Fil

lcondensatesiphonwithwater

(approx.0.5l).

Sta

rtuppumpseveraltimes.

Upo

ncompleteventing,fillsystemto

finaloperatingpressure.

Clo

seventingscrewandremovefil-

linghose.

Replacingsystem

Rin

sesystemcarefully.

Che

ckconnectionsfortightnessand

leaks.

Ventilatesystemcarefully

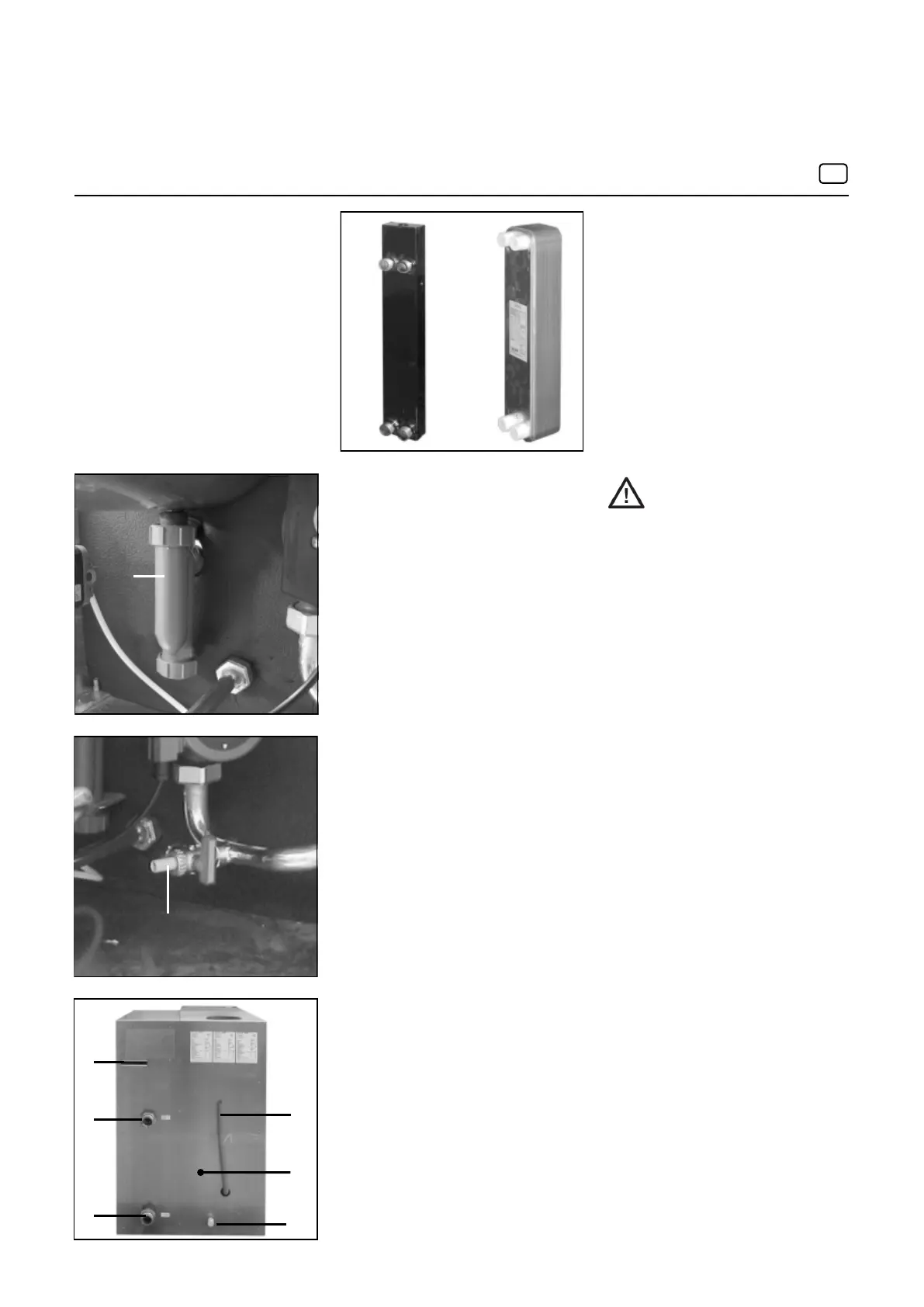

3 Cablepassageforexteriorcable

4 Gasconnector3/4“

5 Flowconnector

6 Returnconnector

7 Condensateconnector

8 expensionvessel

(plateheatexchangeronly)

14

1

2

3

5

6

7

8

4

Con

nectgasline

Che

cklinesfortightnessandleaks

Equipmentmustbeconnectedby

anauthorizedspecialistonly.

Pluginrequiredexhaustconnector

plate(concentric/parallel)

I

nsertboilerconnector(concentricor

parallel)fromthetopintotheintended

openingandpushintoreceivingpipe.

UselubricantsuitableforPPSex-

haustpipes

Con

nectexhaustcollectortoexhaust

system

M

ountconnectingpipe

Installationofinternalhydraulic

accessories

Assemblyofthehydraulicswitchorthe

plateheatexchangerisperformed

followingaseparatemanual.

Thismanualiscontainedinthe

respectiveaccessoryset.

DANGER:

Dangerofpoisoning!Ifthe

siphonisnotfullofwater,orwith

openconnections,fluegasesarising

canputpeopleinmortaldanger.

e

n

Loading...

Loading...