Commissioning

ControlMeasures

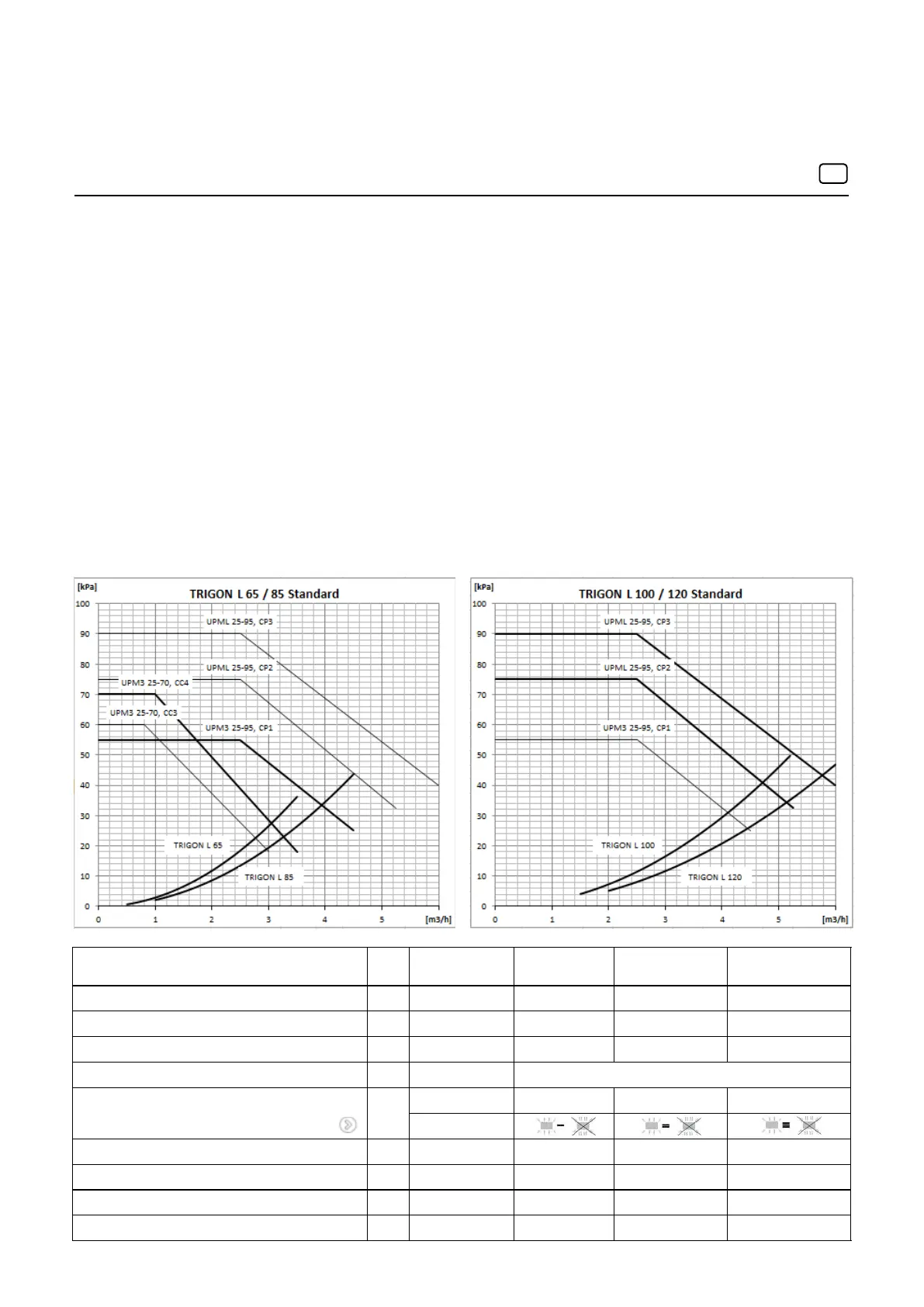

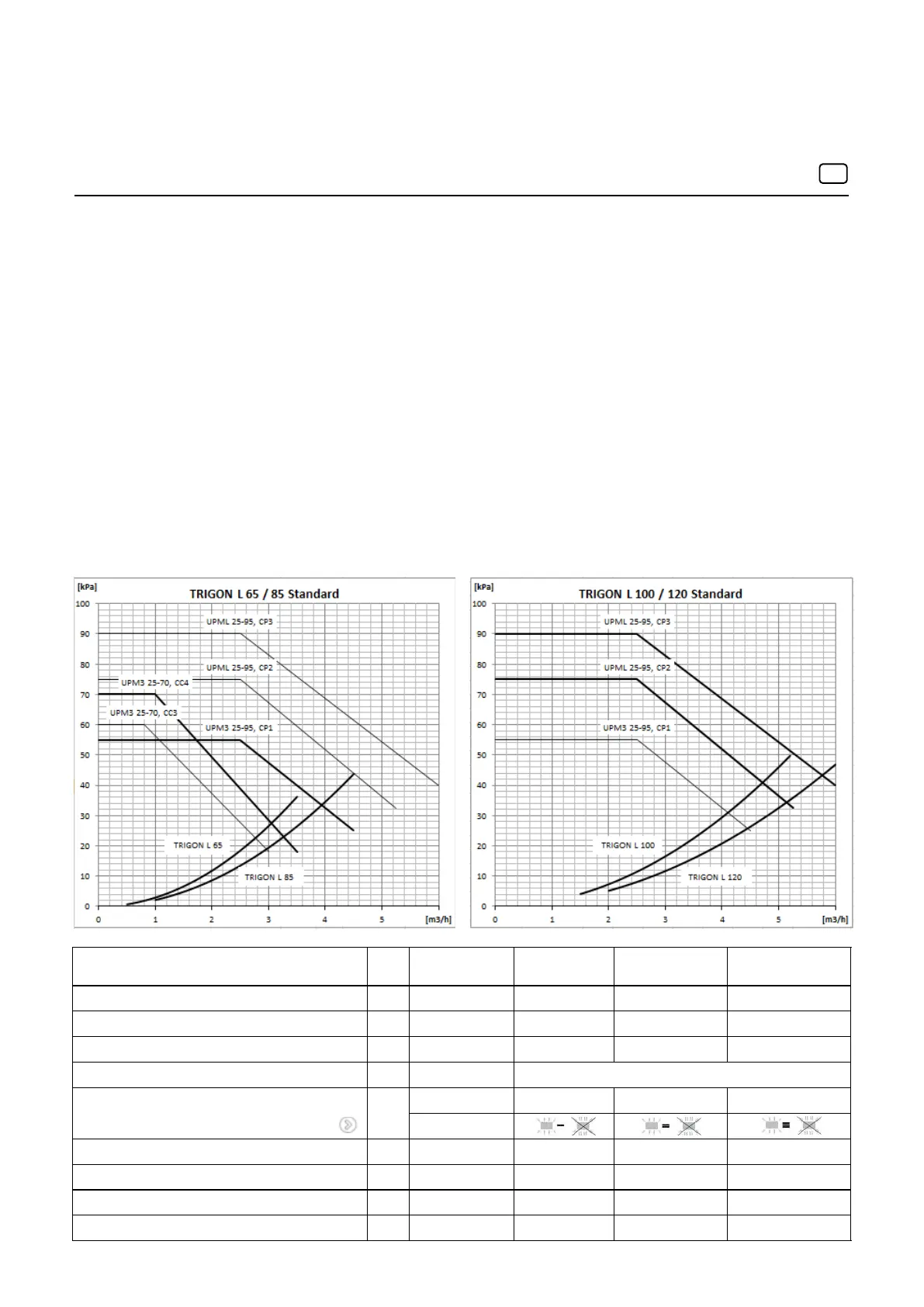

Standardboilers:Pump/Setting/Resistancecurves

16

Th

einitialcommissioningshallbe

performedbyanauthorized

specialistonly

Ingeneral,thefollowingcontrolchecks

mustbeperformedpriortocommissio-

ning:

Checkpowersupply.

Che

ckpressureinheatingsystem.

Che

ckpressureatgasconnection.

Checkgassupplyforleaks.

Checkproperassemblyofexhaust

accessories.

Che

ckcondensatedischargefor

leaks.

Ensurepriortocommissioning

Suf

ficientdimensionsoftheexpansi-

oncontainermustbeascertained.

Complywithnotesonwaterquality,

fillwithsoftenedwaterifnecessary.

Com

missioningofsystemandventing

shalltakeplaceimmediatelyafterthe

fillingprocessinordertoeliminate

standingairpocketsasacenterof

corrosion.

Com

missioningatlowsystemtempe-

raturesandmaximumthrough-flowof

theheatingsystemavoidcalcium

depositsinsidetheboiler.

Dur

inginspectionwork,thecomplete

exchangeofthesystemwatershould

beavoided.Thiscanbeaccomplis-

hedthroughpartialshutoffsor

throughreuseofretainedandfiltered

systemwater.

Minimumcirculationamounts/Flow

monitoring

Youmustensurethatthesystemhas

sufficienthydraulicflowuponheat

demand.Thesystemisequippedwith

aflowsafetydevicewhichmonitorsthe

through-flow.Inordertomaintaina

minimumflow,theinstallationofa

switchoraplateheatexchanger(both

availableasaccessories)is

recommended,ortheconnectionof

theTRIGONLtoanopenmanifold.

Boi

ler

T

RIGONL65

T

RIGONL85

T

RIGONL100

T

RIGONL120

Nom

inalheatinputHimax

k

W

60

.7

80

.0

90

.0

11

2.4

M

inimumheatinputHimin

k

W

8.6 16

.0

18

.0

22

.5

Nom

inalwaterflowatdT=20K

m

3

/

h

2.6 3.4 3.9 4.8

Pumptypespeedcontrolledpump UPM325-70 UPML25-95AUTO

Pum

pfactorysetting:

CC4 CP1 CP2 CP3

LED

T

otalheadatnominalflow

kP

a

34 41 48 50

M

aximumavailableheadforsystem

kP

a

14 16 20 20

M

axpowerconsumptionpump

W 53 80 11

0

14

0

T

otalmaxpowerconsumption(boiler+pump)

W 19

3

27

4

33

2

38

5

e

n

Loading...

Loading...