02/2011 - Art. Nr. 4200 1029 5200B20

Commissioning

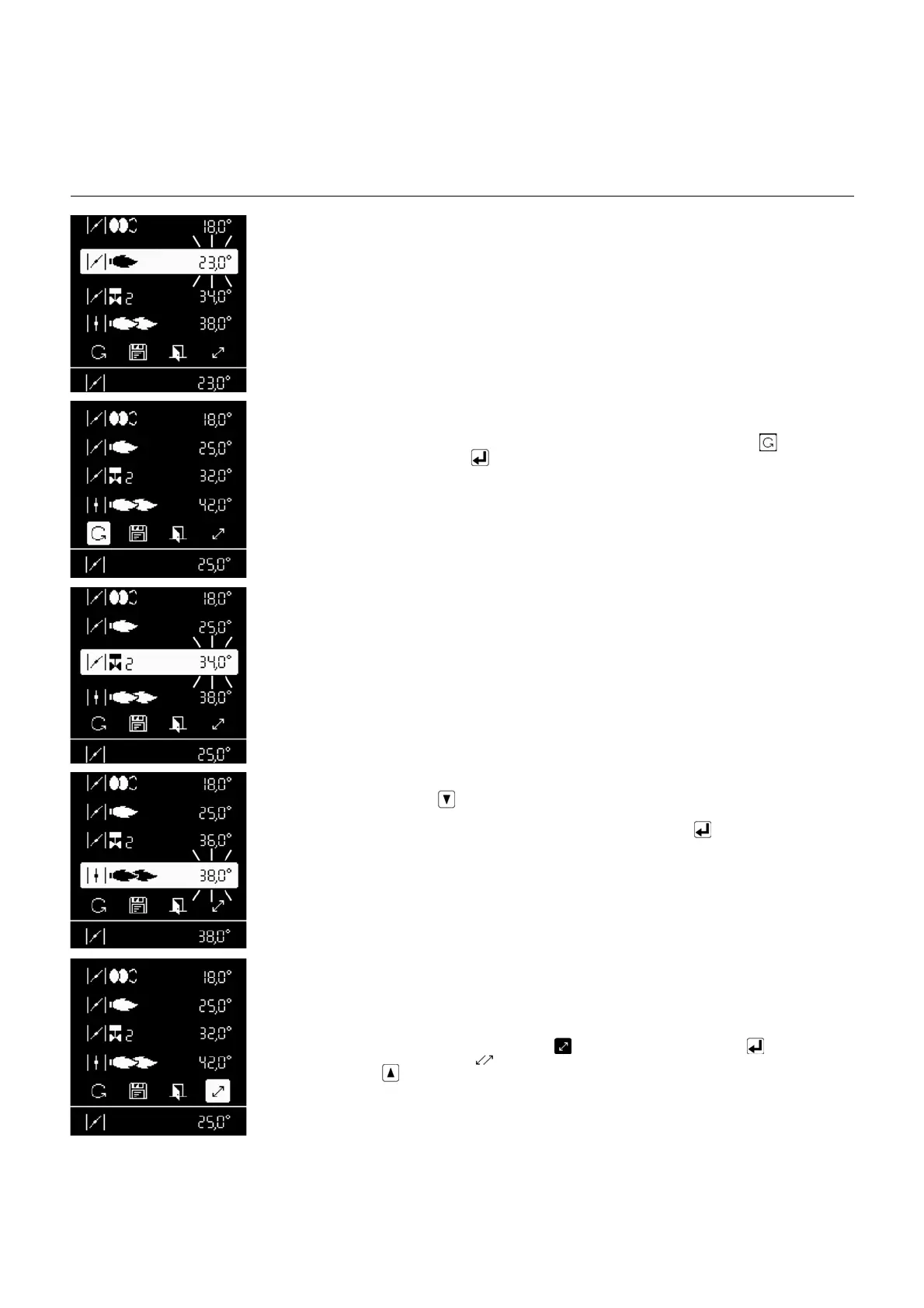

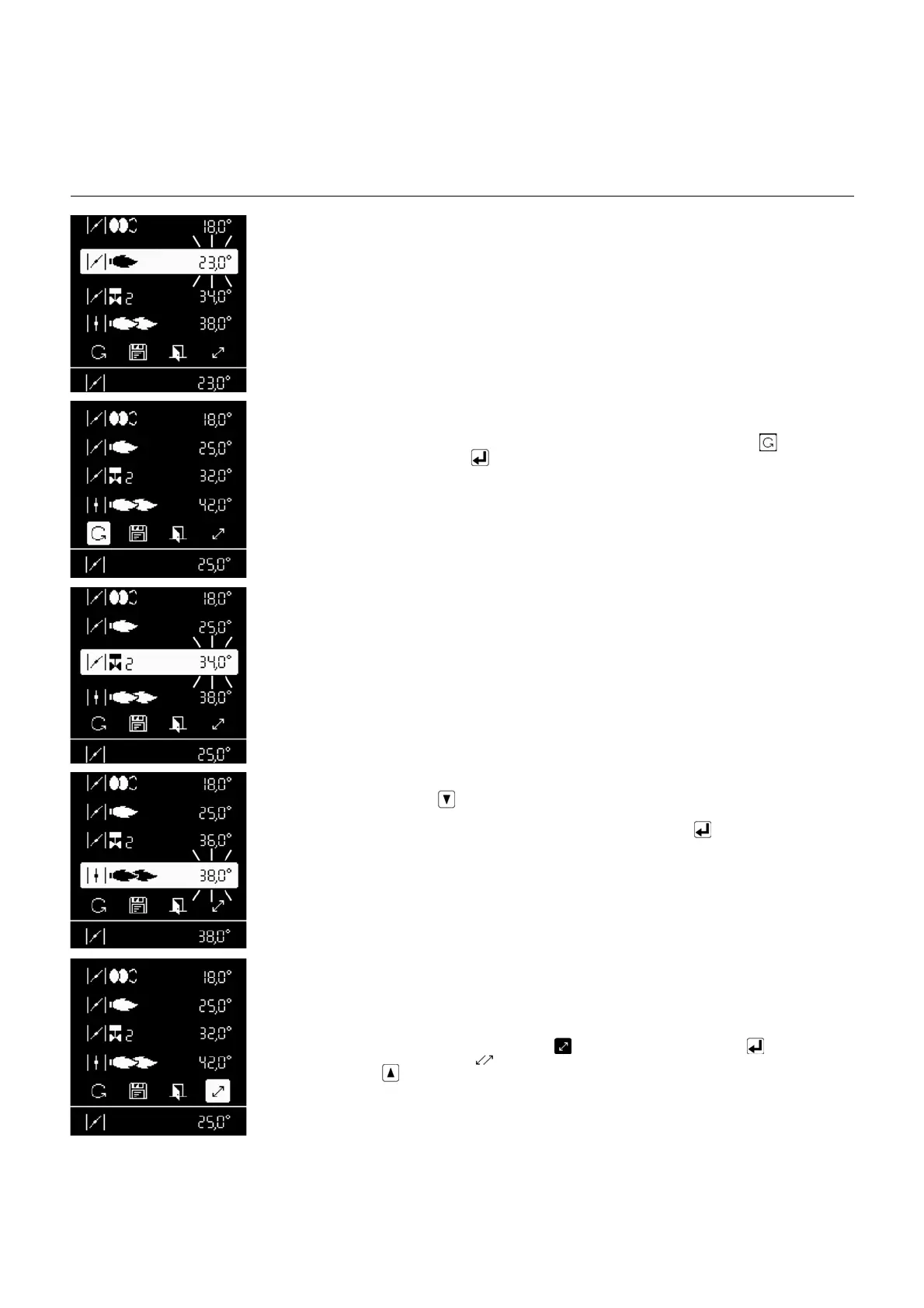

Setting the flame

Setting the 1st stage

If the flame has been detected, the control unit sets the burner to the 1st stage as soon as it

receives the regulation authorisation.

- Adjust the gas pressure for the 1

st

stage depending on the required output, using the regulator

on the gas valve. Monitor the combustion values continuously as you do so (CO, CO

2

, soot

test). If necessary, adjust the dimension Y and/or adapt the airflow.

- To do this, modify the position of the servomotor in 1

st

stage. Proceed as described on page

17, in the paragraph "Modifying the value of a servomotor position setting"

- Precautions: when modifying the setting value, the servomotor will move in real time. As a

consequence, the combustion values must be constantly checked.

Specific function: ignition checking

If the ignition position has been modified, it is possible to carry out a new burner start-up to check

the new ignition position, without having to quit the settings menu.

To do this, after modifying the ignition position, position the cursor on the symbol , and initiate

the new start-up using the button .

Setting the opening position of the 2

nd

stage gas valve

After the 1

st

stage is set, it is possible to set the opening value for the 2

nd

stage gas valve.

Proceed as described in the paragraph "Modifying the value of a servomotor position

setting"

- Precautions: in this case the servomotor does not move immediately, but first remains in the 1

st

stage position (the actual position of the servomotor is always displayed in the lower part of the

display). The 2

nd

stage valve also remains closed.

Setting the 2

nd

stage

To set the position of the air flap in the 2

nd

stage, position the cursor on the corresponding line on

the display using the button .

- To make the burner actually switch to the 2

nd

stage, press the button again. The servomotor

will then move the air flap to the set position. At the same time, the 2

nd

stage gas valve will open,

as soon as the opening position set for the servomotor is passed.

- Adjust the gas pressure for the 2

nd

stage depending on the required output, using the regulator

on the gas valve. Monitor the combustion values continuously as you do so (CO, CO

2

, soot

test). If necessary, adjust the dimension Y and/or adapt the airflow. To do this, modify the

position of the servomotor in the 2

nd

stage. Proceed as described on page 17, in the paragraph

"Modifying the value of a servomotor position setting"

- Precautions: when modifying the setting value, the servomotor will move in real time. As a

consequence, the combustion values must be constantly checked.

Specific function: position the opening and closing of the 2

nd

stage gas valve differently

The control unit has the possibility of setting the opening of the 2

nd

stage valve, when the 1

st

stage

changes to the 2

nd

stage, at a different position to that for closing when the 2

nd

stage drops to the

1

st

stage.

- To do this, position the cursor on the symbol and confirm with the button . The selected

symbol will change like this one .

- Using the button , position the cursor on the setting value of the 2

nd

stage gas valve. It is

possible to adjust to different values resp. during 1

st

stage operation the opening position, and

during 2

nd

stage operation the closing position.

Loading...

Loading...