11/2010 - Art. Nr. 4200 1029 8600A 13

Commissioning

Checks before commissioning

Adjustment data

Checking combustion components

Checks before commissioning

The following must be checked before

initial commissioning:

• That the burner is assembled in

accordance with the instructions given

here.

• That the burner is pre-set in

accordance with the values in the

adjustment table.

• Setting the combustion components.

• The heat generator must be ready for

operation, and the operating

regulations for the heat generator

must be observed.

• All electrical connections must be

correct.

• The heat generator and heating

system must be filled with water and

the circulating pumps must be in

operation.

• The temperature regulator, pressure

regulator, low water detectors and any

other safety or limiting devices that

might be fitted must be connected and

operational.

• The exhaust gas duct must be

unobstructed and the secondary air

system, if available, must be

operational.

• An adequate supply of fresh air must

be guaranteed.

• The heat request must be available.

• Fuel storage tanks must be full.

• The fuel supply lines must be

assembled correctly, checked for

leaks and bled.

• A standard-compliant measuring point

must be available, the exhaust gas

duct up to the measuring point must

be free of leaks to prevent anomalies

in the measurement results.

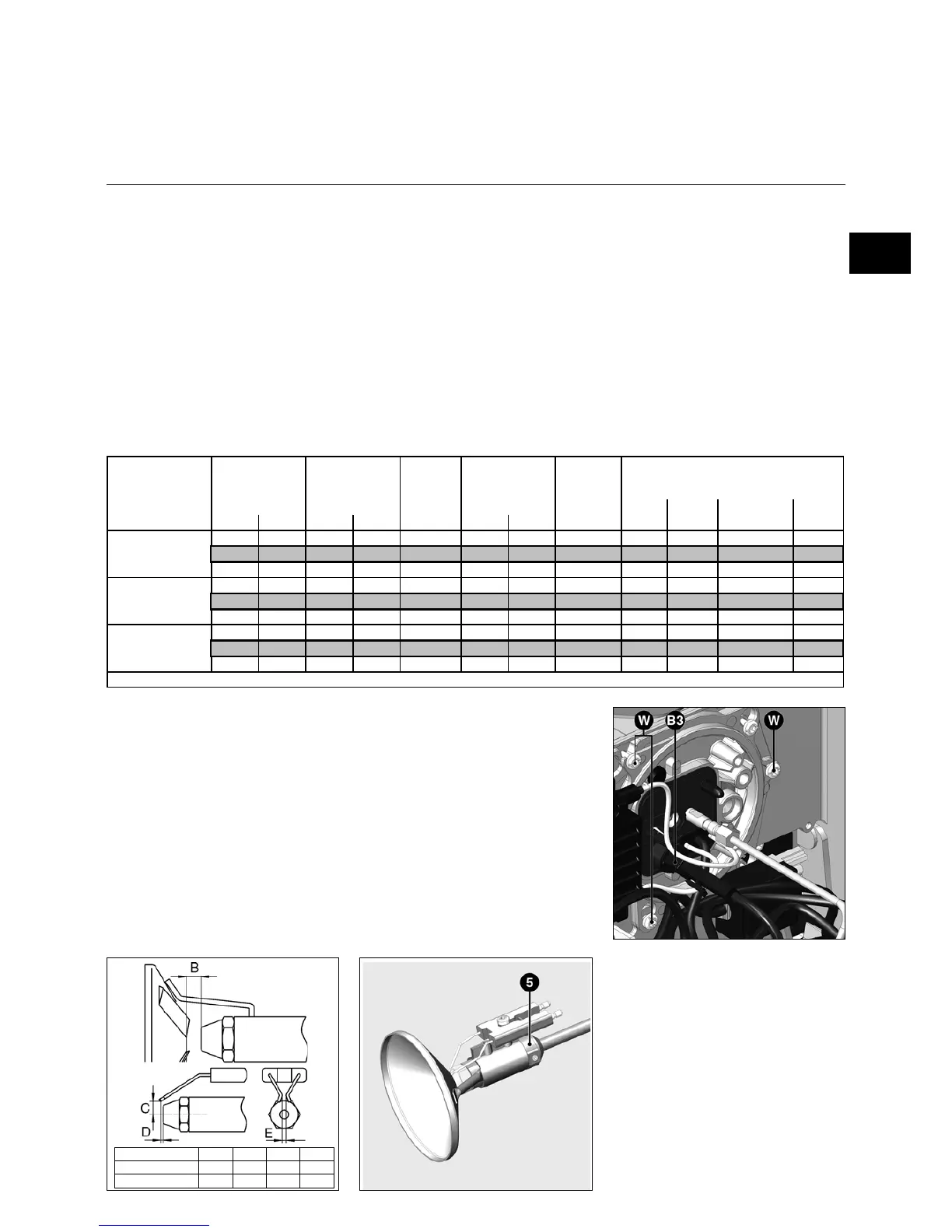

The settings data below are basic

settings. The factory settings data is

highlighted in bold and with a grey

background. With a normal case, these

settings enable the commissioning of

the burner. In all cases, carefully check

the settings values. In most cases,

according to the installation, corrections

must be made.

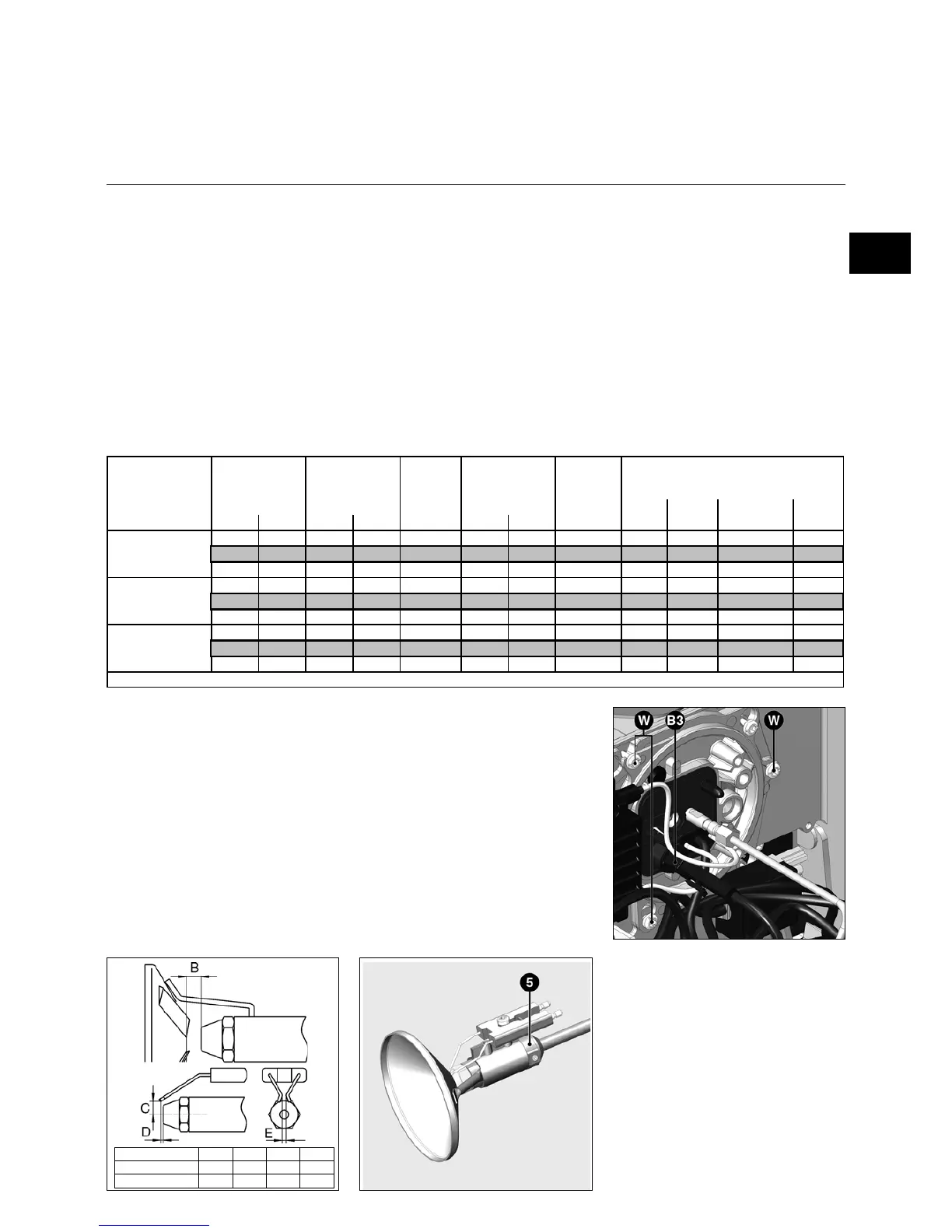

Checking checking combustion

components

• Disconnect the ignition cable on the

transformer side.

• Loosen the nozzle supply line.

• Loosen the three cover screws W.

• Remove the cover and remove the

mixture ignition device.

• Check nozzle sizes and exchange in

accordance with the parts specified in

the above table if necessary.

• Check the adjustment of the ignition

electrodes block and the baffle plate

and adjust if necessary.

• Check the gap between nozzle and

baffle plate and adjust if necessary.

1. stage 2. stage 1. stage 2. stage 1. stage 2. stage

60 80 5 7 1,35 11 22 20 30 30 40 50

70 100 6 8 1,50 11 22 30 30 30 40 60

90 120 8 10 2,00 11 22 35 35 35 40 60

80 110 7 9 1,75 11 21 25 30 30 40 50

100 140 8 12 2,25 11 22 30 35 35 40 90

110 160 9 13 2,50 11 22 35 35 35 40 90

100 140 8 12 2,25 11 22 15 35 35 40 70

125 170 11 14 2,75 11 22 20 40 40 65 90

150 210 13 18 3,00 11 21 35 50 50 65 90

Burner

2. stage

Stage

changeover

Ignition

Combustion head settings

Head setting values (space between

nozzle and turbulator - dimension B,

space between nozzle and ignition

electrodes - dimension C) can be

checked with enclosed drawing. The two

dimensions are set in the factory.

Dimension B was set thanks to adjust

ring 5. While reassembling the turbulator

for a nozzle replacement, it is not

necessary to re-adjust dimension B, as

far as the turbulator is re-assembled on

the stop on ring 5.

Loading...

Loading...