5 Press dolly on to sample for about 10

seconds.

2 Ensure test surface of dolly is clear of

old adhesive - see Section 8.2

‘Cleaning the Dolly’ on page en-7.

4 Apply a thin, even coat of adhesive to

dolly test surface. If adhesive is low

viscosity, see Section 9 ‘Using a Dolly

Plug’ on page en-8.

1 Identify the dolly test surface.

3 Wipe dolly test surface and sample

area with a solvent to remove oil and

grease.

7 If required, score the coating around the dolly using a dolly cutter

- see Section 10 ‘Spares & Accessories’ on page en-9.

6 Leave dolly undisturbed for at least 15 minutes (preferably for 2

hours or more), to allow the adhesive to harden.

www.elcometer.com

en-4

R

3 GETTING STARTED - DIGITAL PRESSURE GAUGE (continued)

The gauge can display readings in MPa (Megapascals) or PSI

(Pounds per Square Inch).

The gauge has a gauge reset function which restores the original

factory settings.

3.3 SELECTING THE UNITS

3 To cancel the reset request, press or to toggle to

‘CANCL’ followed by to confirm.

3 Press to select the units required.

2 Press again to confirm the reset. The gauge will reset and

switch off.

2 Press or to toggle between MPA and PSI.

1 Press until RESET is displayed followed by to select.

1 Press until UNITS is displayed followed by to select.

3.4 RESETTING THE GAUGE

MAX

MENU

MENU

MENU

MAX

MENU

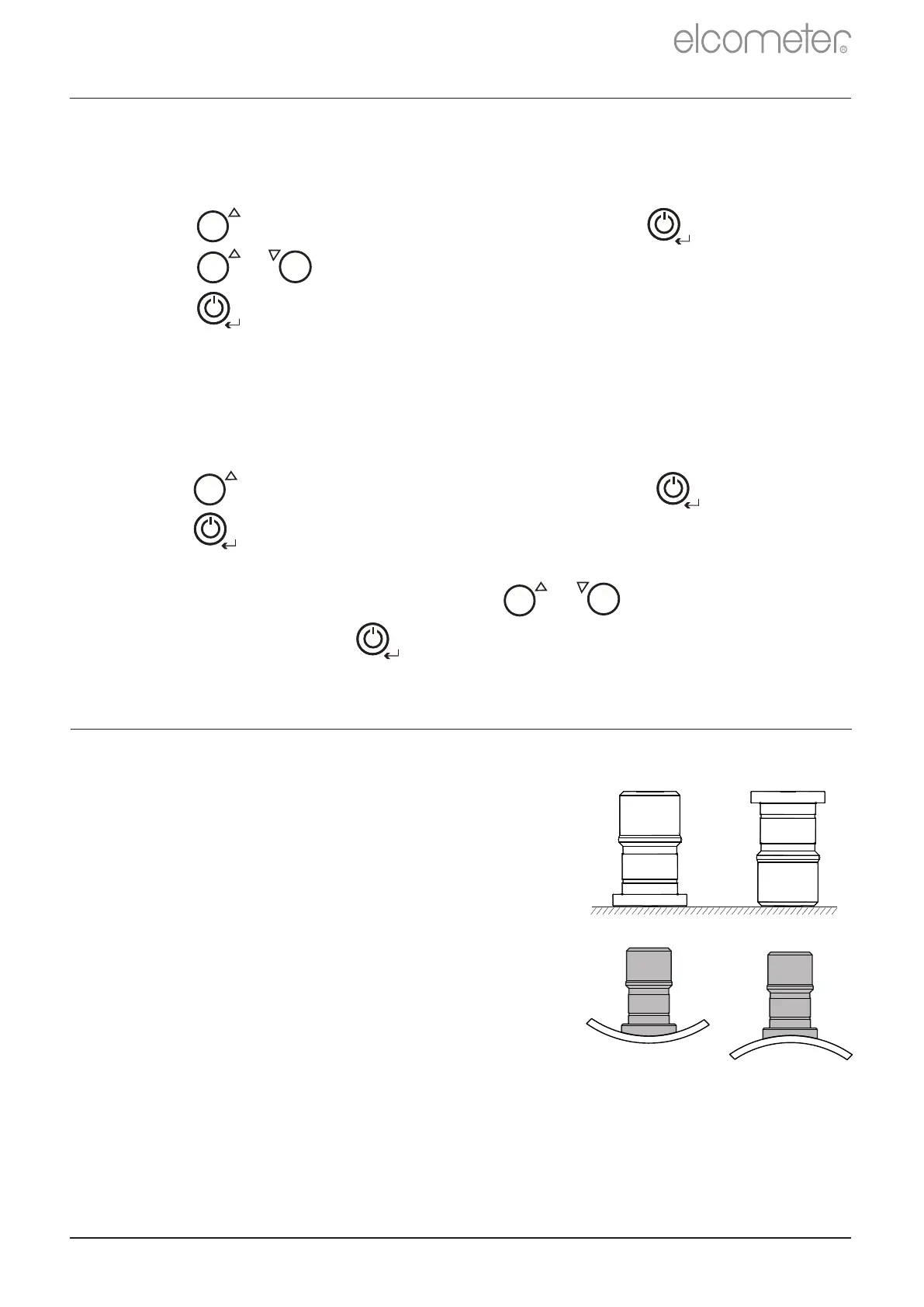

4 SECURING THE DOLLY

û

ü

ü

ü

Loading...

Loading...