2-22 Installation

P/N 0013-1027-005 Rev A

If EMI problems persist, additional counter measures can be attempted. Several suggestions for

systems modifications follow.

1. A ferrite “doughnut” or torroid around a signal cable may help. The ferrite will attenu-

ate common mode noise but will do nothing for differential mode noise. Specifically,

this should help RS232 communication problems.

2. Suppress each switched inductive device that is near the servo amplifier. This includes

solenoids, relay coils, starter coils and AC motors (such as in motor driven mechanical

timers).

3. DC coils should be suppressed with a ‘free-wheeling’ diode connected across the coil

4. AC coils should be suppressed with RC filters (a 200 ohm 1/2 Watt resistor in series

with a 1/2 microFarad, 600 Volt capacitor is commonly used).

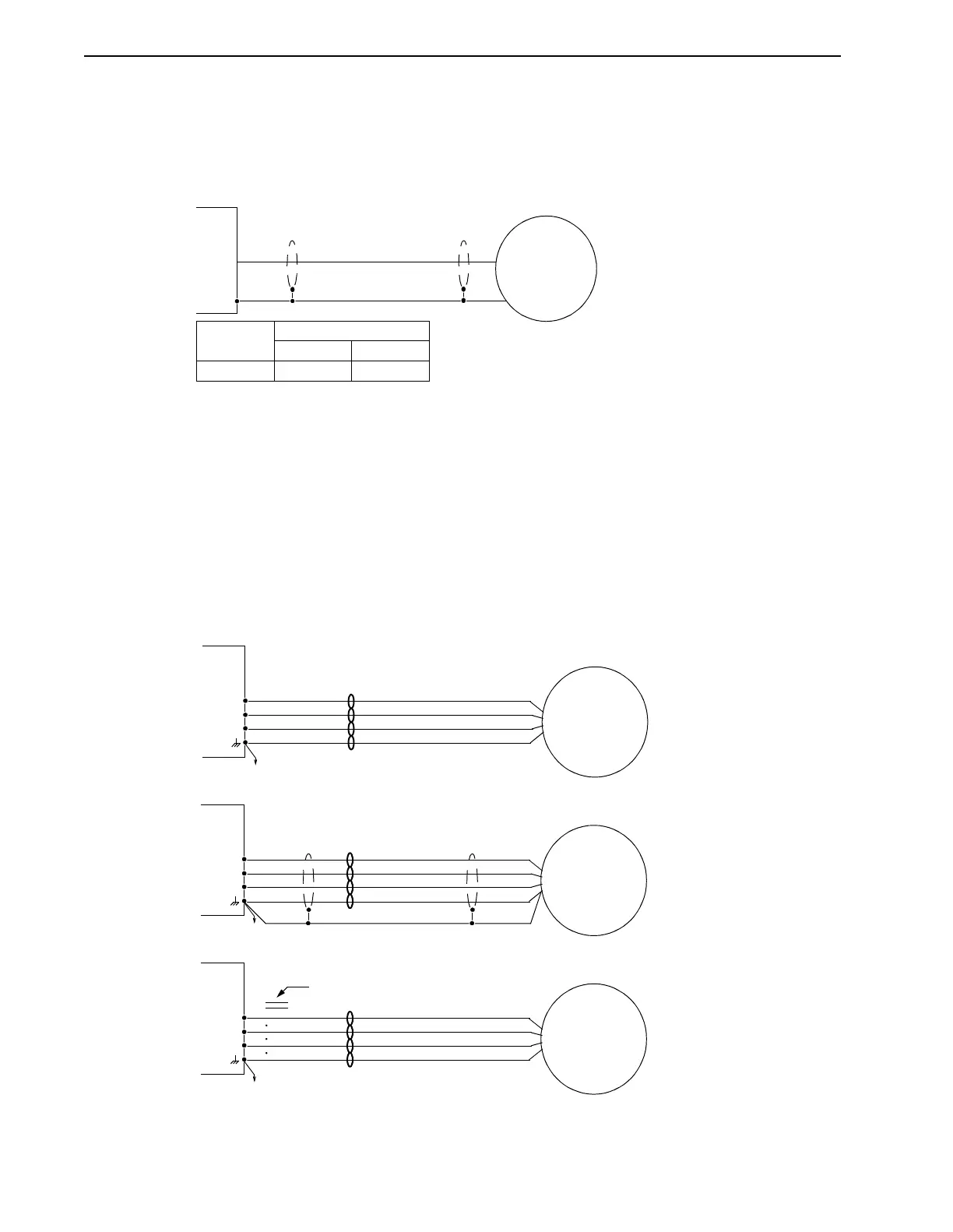

5. Motor Power Windings can be grounded, shielded, and choked to minimize noise emis-

sions.

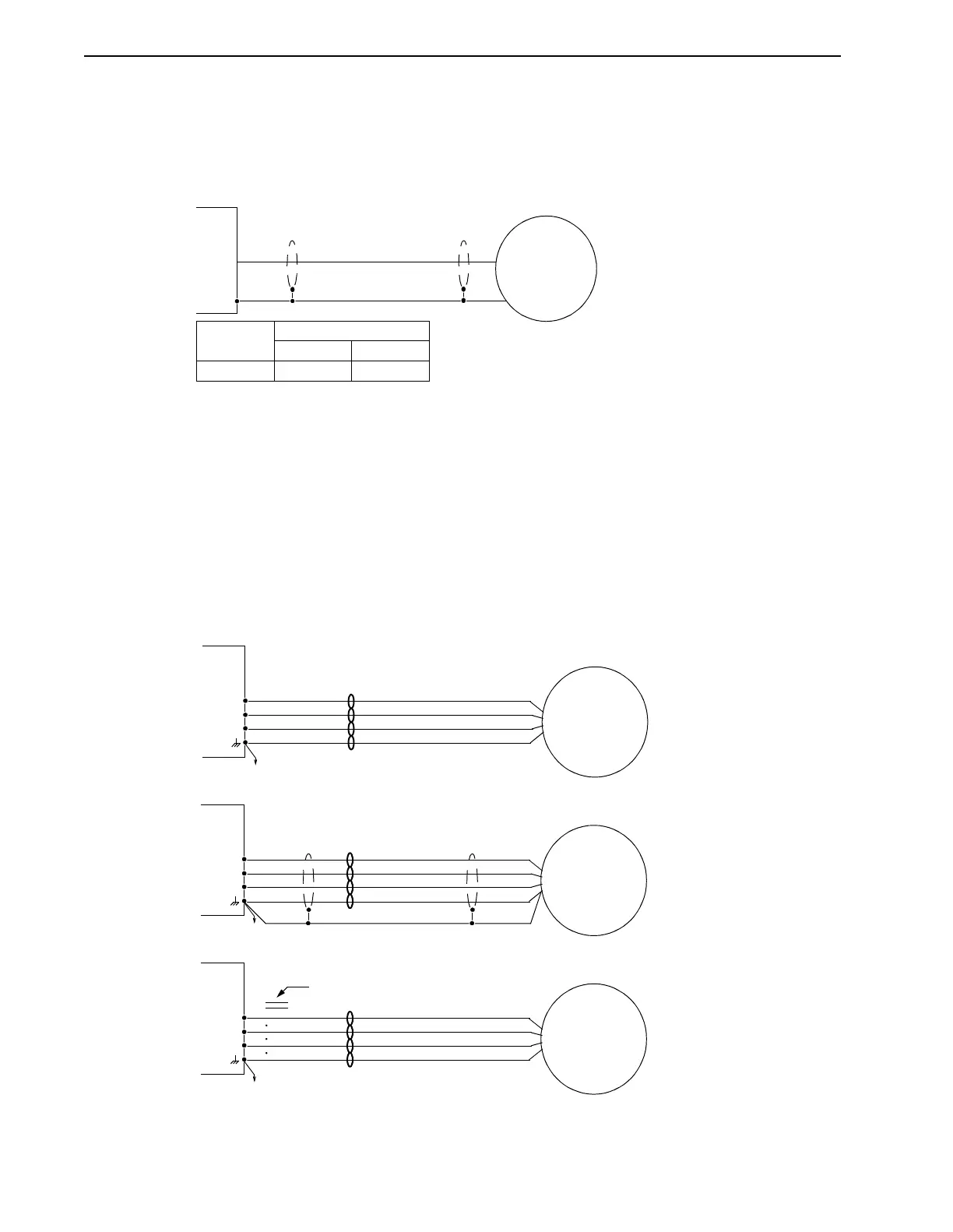

FIGURE 2.16 Torroid Encoder Shielding Method for Brushless Servo Motors

FIGURE 2.17 Motor Power Winding Methods to Minimize Noise Emissions

AMPLIFIER

SHIELD

ENCODER CABLE

MOTOR CASE

BRUSHLESS

MOTOR

Belden Part No. Carol Part No.

Recommended raw cable for

building your own cable

C06258337

Elec-

IQ 2000/

AMPLIFIER

SHIELD

TWISTED TOGETHER

MOTOR CASE

BRUSHLESS

MOTOR

T

S

R

CHASSIS

T

S

R

TO SINGLE POINT

EARTH GROUND

AMPLIFIER

TWISTED TOGETHER

MOTOR CASE

BRUSHLESS

MOTOR

T

S

R

CHASSIS

T

S

R

TO SINGLE POINT

EARTH GROUND

AMPLIFIER

TWISTED TOGETHER

MOTOR CASE

BRUSHLESS

MOTOR

T

S

R

CHASSIS

T

S

R

TO SINGLE POINT

EARTH GROUND

COMMON MODE CHOKE

(10-20 TURNS ON COMMON

FERRITE TOROIDOL CORE)

Loading...

Loading...