Product Description

Page 30 of 62 User Manual QT50 Doc ID 1321 version 2.0 Sept. 2018

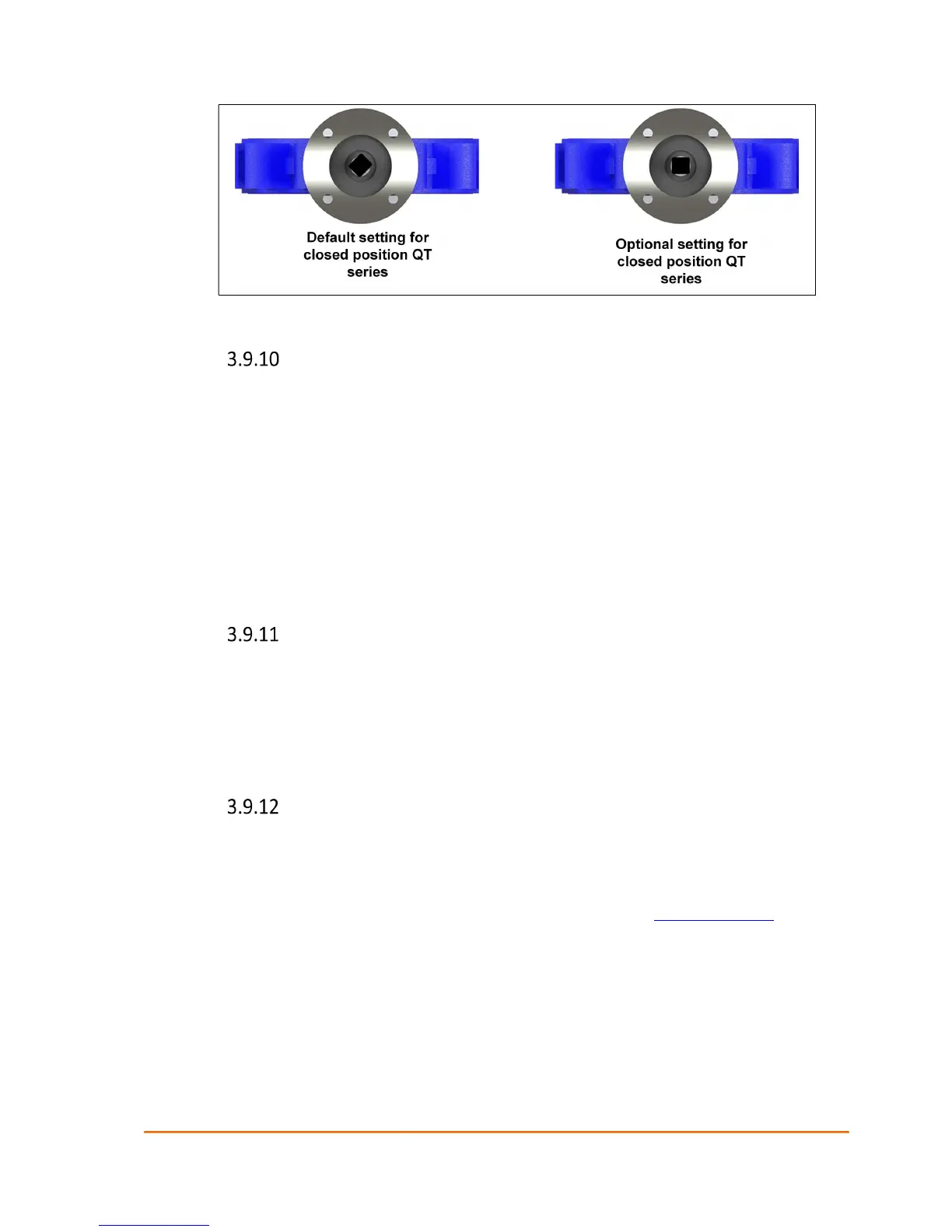

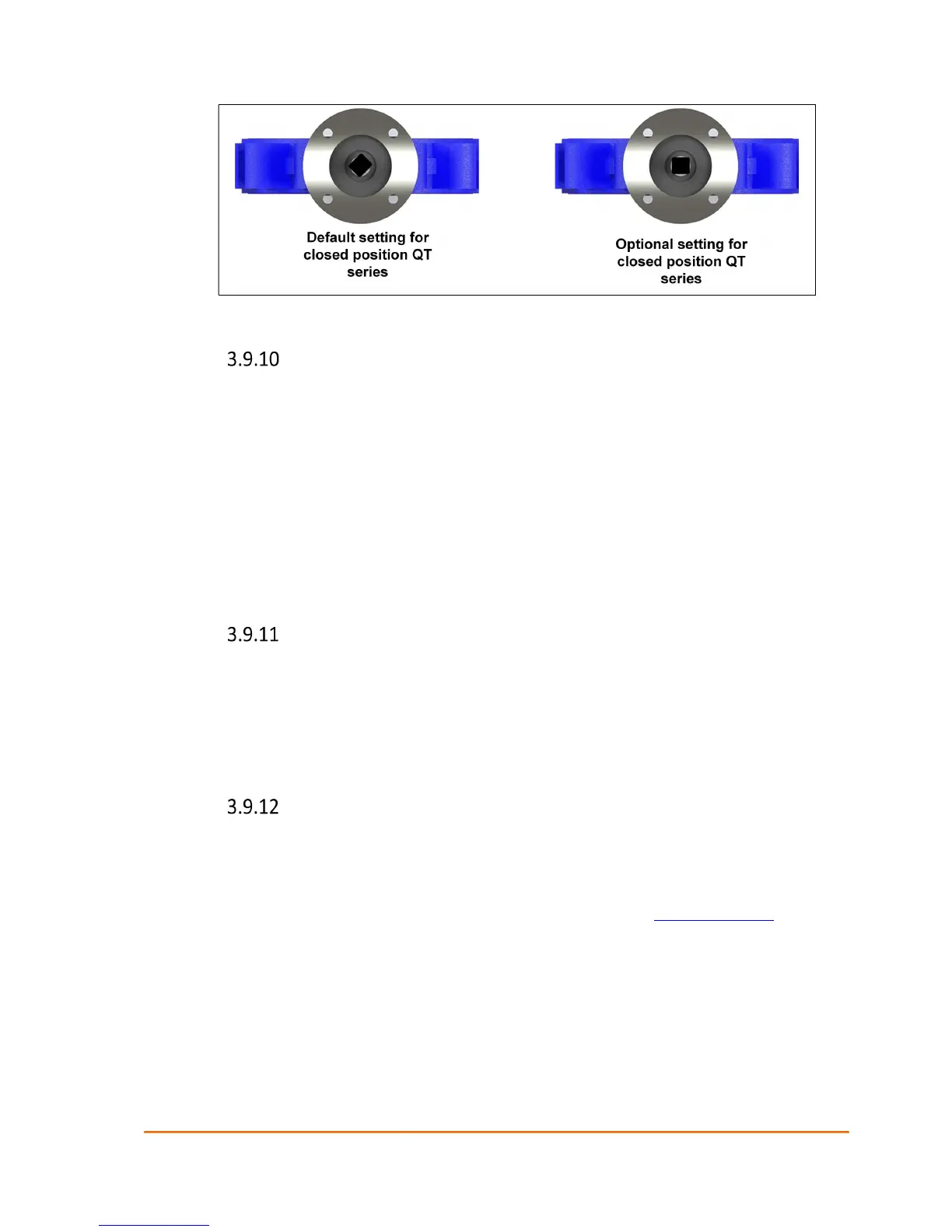

Figure 13: QT 50 Settings for closed position

Torque considerations for valve and actuator

The actuator must have sufficient torque to operate the valve in all situations

with an acceptable safety margin. Valve type, temperature, operating pressure,

medium density and viscosity and the medium’s effect on the valve friction are

among the variables that need to be evaluated. A change in any of these

variables may change the required operating torque. Preferable a torque table

with all parameters should be used, but for an electrical actuator, the output

torque is constant, reducing the considerations to be made. Using the break to

open (BTO) value usually gives a correctly sized actuator. The break to open

torque is defined as the torque required to move the valve out of the seat.

Be aware that the MAST of the valve needs to be verified to prevent damage to

the stem. Eltorque can assist with the necessary experience in selecting the

correct size of the actuators for the valve.

Closing time

For the QT50 the closing time is configurable within a predesigned interval. The

opening and closing profiles are shown in Table 5: System performance

parameters for QT50 actuators on page 17.

For the QT50, the closing time is configurable within a predesigned interval.

Hence, the opening/closing profile can be optimized to fit most system

specifications.

Configuration

The actuator is configured from a computer and it is delivered with the

configuration specified by the customer. Eltorque provides the E3C

configuration software which runs on a standard PC and the corresponding User

Manual E3C Software.

The software can be downloaded from the Eltorque website www.eltorque.no –

Technical Support – Software.

The Eltorque Configuration Cable is needed to connect the actuator to the

configuration PC/PLC. It must be ordered separately, see Chapter 8 Ordering

Information and Recommended Spare Parts on page 55.

Loading...

Loading...