Technical Guide

DAN-LIQ-TG-44-rev0813

November 2013

Section 7

POWER CYLINDER OPERATED VALVES

Model 531, 535, 578 and 588 (N.C.) Pressure to Open and Model 532 and 536 (N.O.) Pressure to Close

Power cylinder operated valves can perform various functions. The power cylinder can be full open or closed or the pressure can

be regulated for two-stage batch control or digital batch control.

All valves employ a bias spring in the power cylinder. There is no spring behind the main valve piston. The power cylinder spring

requires 30 psi to make a full stroke. An optional spring to make a full stroke at 15 psi is available for selected applications.

These valves use the line product or an auxiliary supply pressure (pneumatic or hydraulic) to operate the power cylinder. The

main valve piston and the power cylinder piston are of balanced design.

The valves are used in a variety of applications such as:

1. Automatic tank safety shut-off

2. Line block valve

3. Emergency shut-off or opening

4. Batching, single or two-stage operation, or digital batch control

The pressure drop across the valve is very low as it follows a Cv curve. Anytime the valve is closed, it is inherently a check valve

without adding any additional controls. The main valve piston is balanced at all positions.

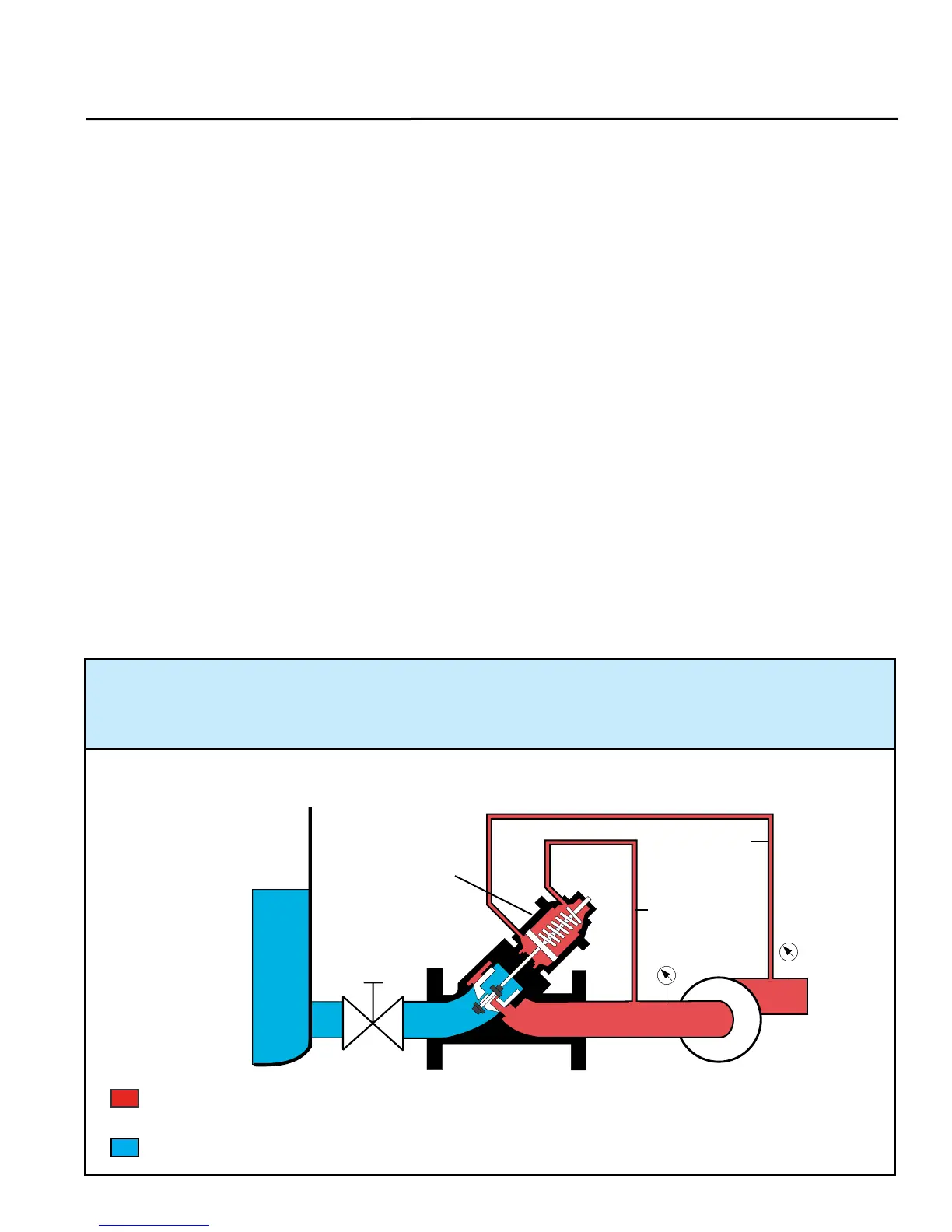

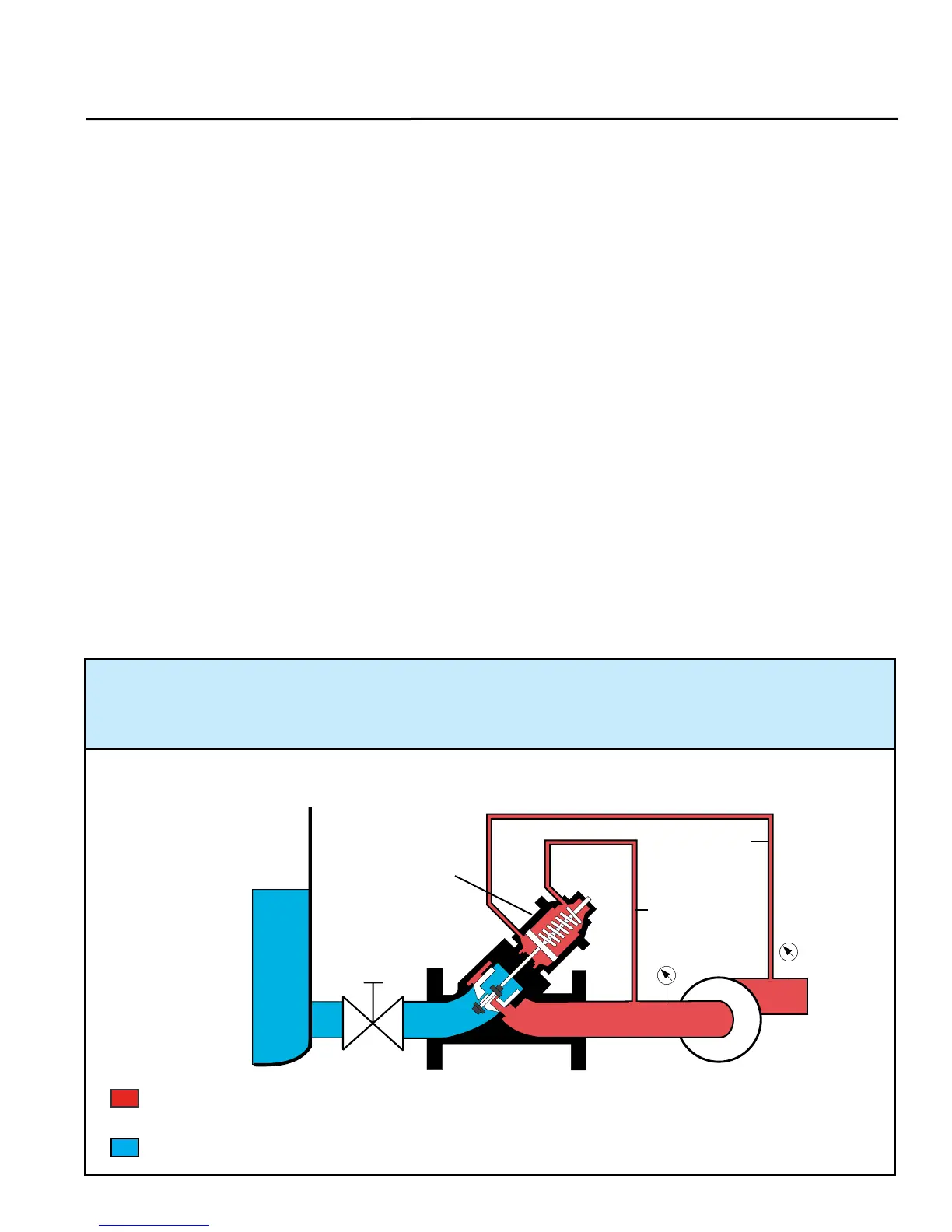

TANK SAFETY CONTROL

36

= Pump and Valve

Outlet Pressure

= Valve Inlet Pressure

CLOSED POSITION - The differential pressure between (P1) and (P2) is less than the spring force of the power

cylinder spring. This indicates the pump is not running or insufficient differential pressure (P1 minus P2) to

overcome the spring force of the power cylinder spring. The power cylinder spring provides the differential

force to close the main valve piston and/or keep it seated.

Figure 7-1

P2

P1

Sense

Line (LO)

Sense

Line (HI)

Power

Cylinder

Pump

Technical Guide

DAN-LIQ-TG-44-rev0208

February 2008

Loading...

Loading...