Technical Guide

DAN-LIQ-TG-44-rev0813

November 2013

43

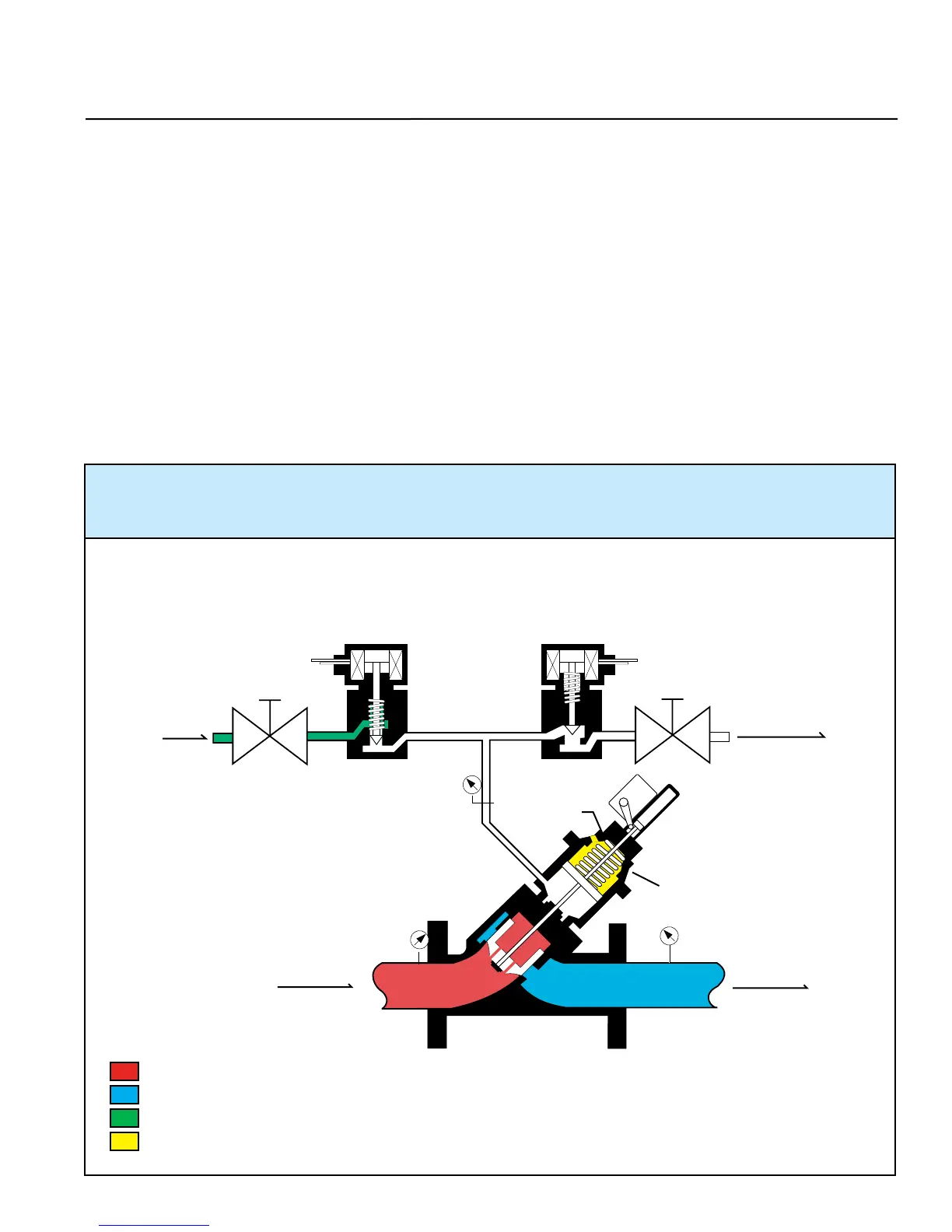

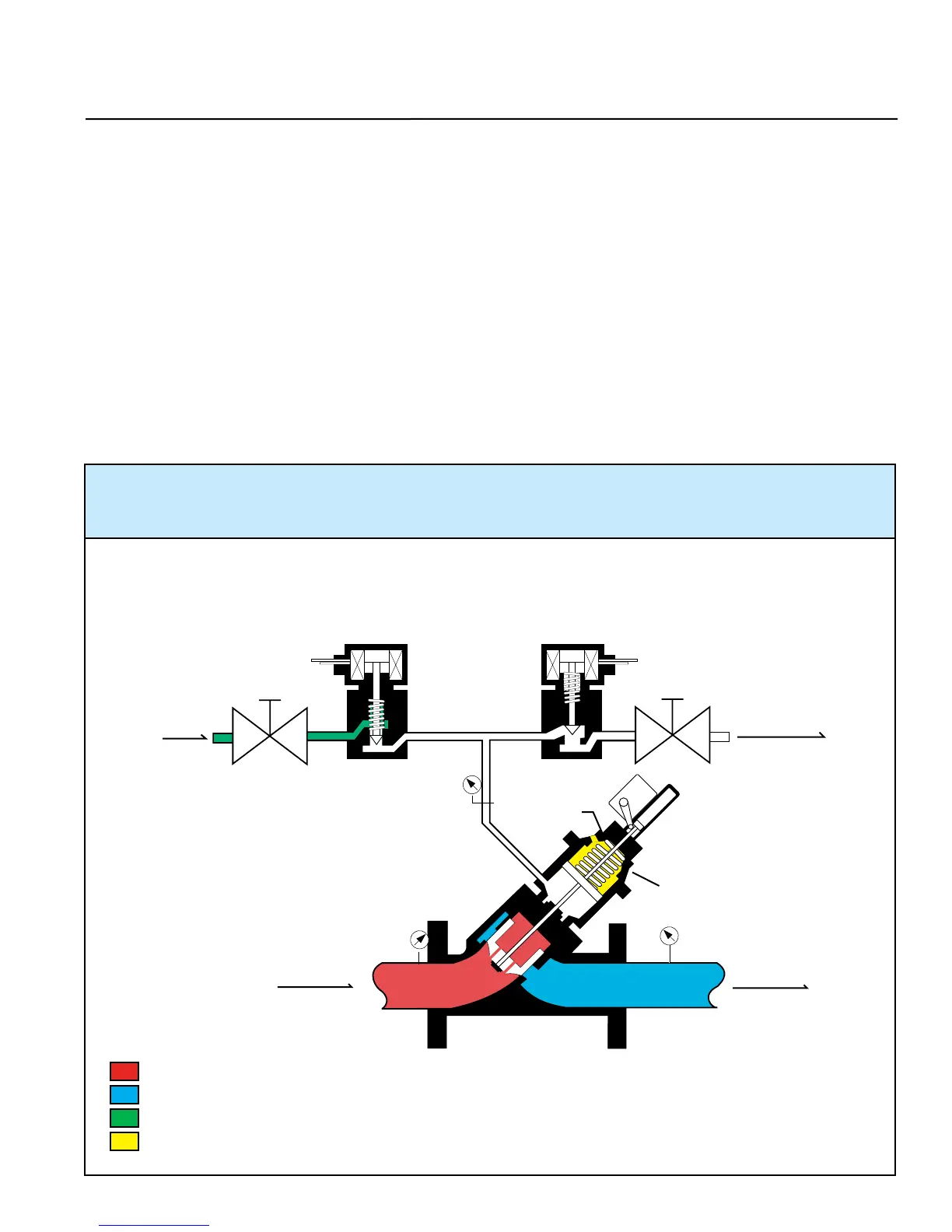

TWO STAGE VALVES

Model 578 (N.C.) Two-stage Electric Shut-off Valve

Two-Stage Control electric shut-off valves are normally closed (N.C.) and they will open only when both solenoids are energized.

The valves are fail-safe as they close upon loss of auxiliary power medium. They use an auxiliary power source (typically

regulated instrument air) to open and position the valve for high and low flow. Flow limiting control is not available. An electrical

supply controlled by a preset is the source of power for energizing the two solenoids.

These valves are used mainly for batching and they provide a means of reducing the rate of flow on startup and before final

shut-off of a predetermined delivery. This minimizes surges of pressure and line shock and assures ±1/4 gallon shut-off (sizes

2" - 6") of the preset volume.

The total system consists of four pieces of equipment: (1) a flow meter, (2) a preset counter, (3) dual sequencing switches, and

(4) a two-stage electric shut-off valve. The preset counter is the device used to set the predetermined volume of liquid that is

to be controlled by the valve. The valve closes in two stages. The first stage closure reduces the flow rate through the valve to

approximately 10% to 20% of the rated capacity of the meter. The second stage closes the valve when the predetermined volume

of liquid has passed through the meter. See Figures 7-8, 7-9 and 7-10.

CLOSED POSITION - The normally closed solenoid is closed. The normally open solenoid is open, venting the

power cylinder pressure (P3) to atmosphere. The power cylinder spring provides the differential force to close

the main valve piston and keep it seated. The closing speed needle valve controls the closing speed.

40

Figure 7-8

= Inlet Pressure

= Outlet Pressure

= Power Cylinder Supply Pressure

= Power Cylinder Spring Force

Solenoid (N.O.)Solenoid (N.C.)

Opening

Speed

Closing

Speed

Supply

Pressure

(30 PSI Max)

Exhaust

Power

Cylinder

Vent

Flow

P2

P1

P3

Loading...

Loading...