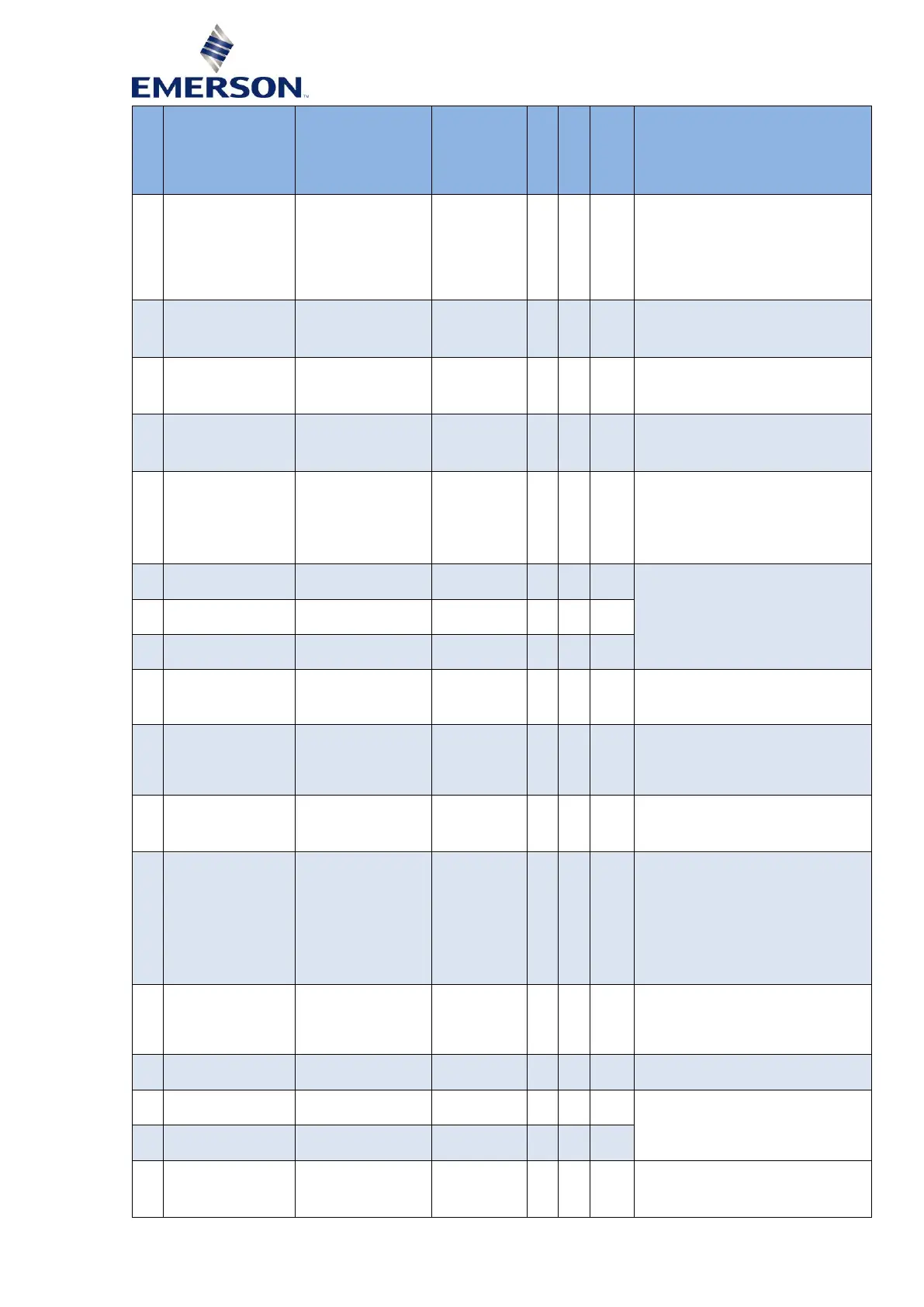

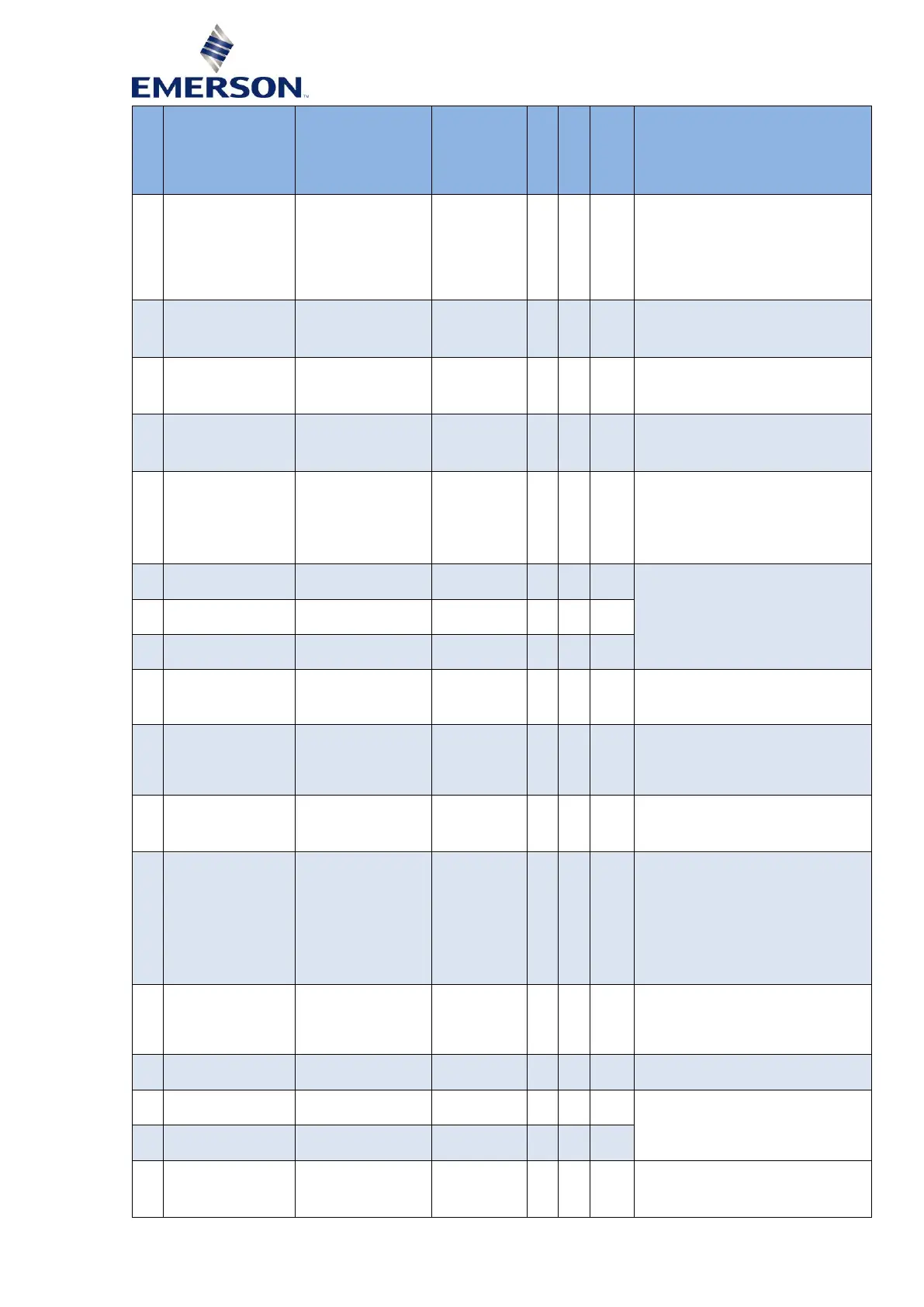

Static, dynamic &

recovery limits

Check &

corrective action

Compressor phase

current foldback timeout

If compressor is running

outside the envelope for

30 seconds.

In Active Envelope

protection mode the

compressor is allowed to

run outside for a longer

time.

Check if the compressor is running within the

envelope. Check the envelopes in Appendix 4

and read chapter 4.4 for further information on

Envelope Control.

Module temperature

foldback timeout

Speed-drop protection

limit / recovery value

EV3150B, EV3185B:

108 °C / 103 °C

Check if the fan is on and working properly. If

the fan is broken, the module will overheat, and

the drive will report this fault.

Input current foldback

timeout

Speed-drop protection

limit / recovery value

EV3150B: 30 A / 28 A

EV3185B: 41 A / 39 A

Check the compressor load. This fault will be

triggered if the load is too high for a certain

speed during 30 seconds.

This fault will be triggered if the fan stops

working. If the fan has been replaced, check the

connections as per instructions in chapter 7.2.

If the fan still does not work, replace the drive.

Drive module HW

overcurrent

This fault appears when there is a short

between phases or in case of a locked rotor

event. Check if the connections between drive

and compressor are properly made and restart

the drive.

If the fault persists, replace the drive, as the

power module might be damaged.

Compressor U phase

overcurrent / sensor fault

If this fault appears, it can only be cleared with a

power cycle on the drive. Check the wiring to

the compressor and run the motor again.

If the fault persists, replace the drive.

Compressor V phase

overcurrent / sensor fault

Compressor W phase

overcurrent / sensor fault

EV3150B: 28 A RMS

EV3185B: 39 A RMS

Send a clear fault command then restart the

compressor. Adjust the load so that the output

current does not exceed 38 A for 18.5 kW and

27 A for 15 kW.

Compressor start-up fault

This fault is triggered when the compressor fails

to start 3 times. Check if the wires are correctly

connected to the compressor. If it still fails, try

interchanging two wires and restart the

compressor.

This fault will appear at start-up if the HPS is not

connected. If it is not used, a short must be

made on the HPS terminals. The fault can only

be cleared with a power cycle.

Compressor motor phase

current imbalance

The difference between the maximum and

minimum compressor phase currents RMS

value exceeds 4 A. Check the compressor

U,V,W connections first, and make sure that the

screws are tight.

If the problem persists, check the values of the

compressor currents with the scope. If a

difference in currents can be observed on the

scope, replace the drive first. If the fault

persists, the compressor must be replaced.

The maximum value of

input voltage (RMS)

exceeds 1.5 x the

minimum value of input

voltage

Check the connection to the grid. This fault will

be triggered when a phase is not properly

connected.

EV3150B: 31 A RMS

EV3185B: 42 A RMS

The compressor load is too high. Try reducing it

and check if the fault still appears.

ADC base AD > 2662 or

ADC base AD < 1433

Restart the drive.

If the fault persists, replace the drive.

Check that all motor U,V,W phases are properly

connected and that there is no loose cable. This

fault is triggered when one of the motor cables

is not connected.

Loading...

Loading...