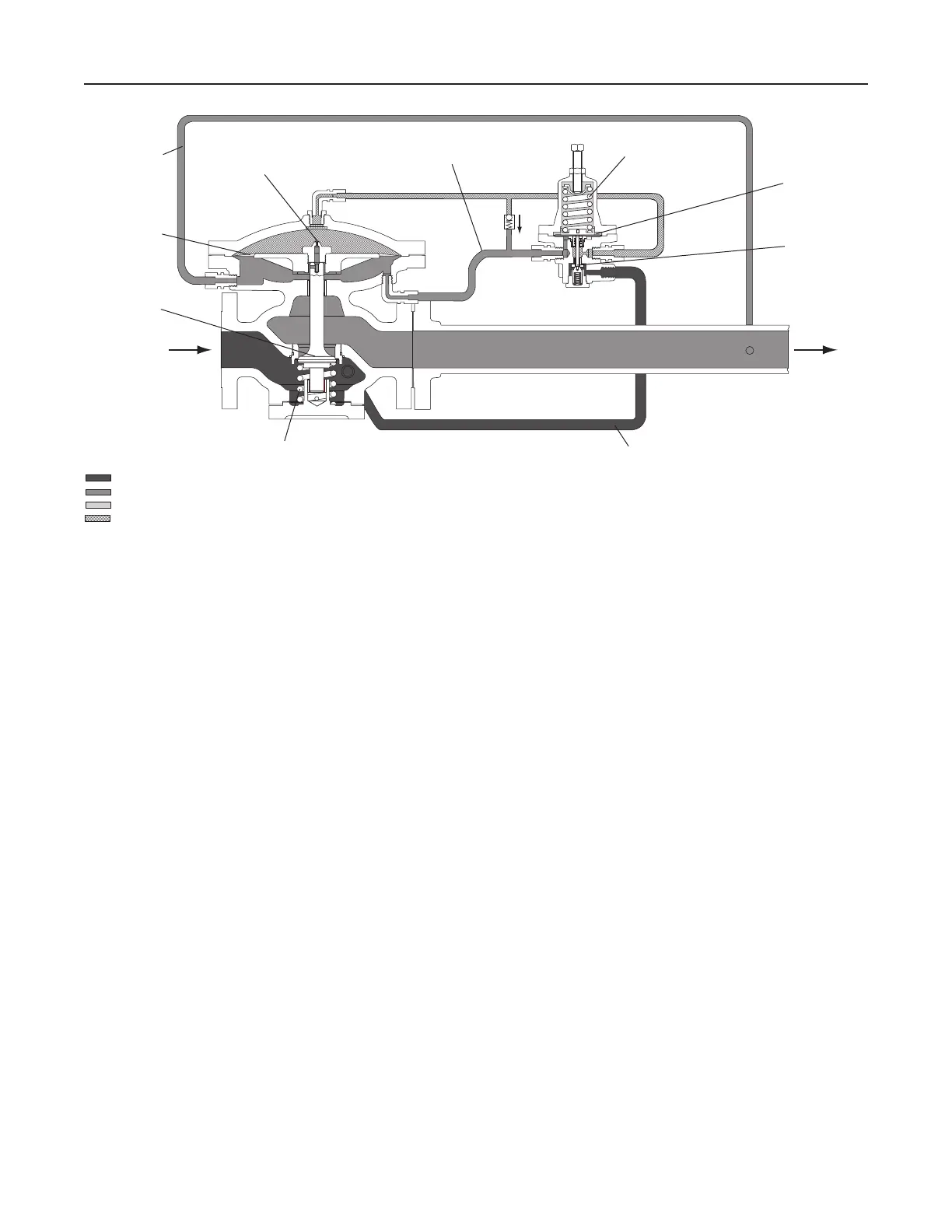

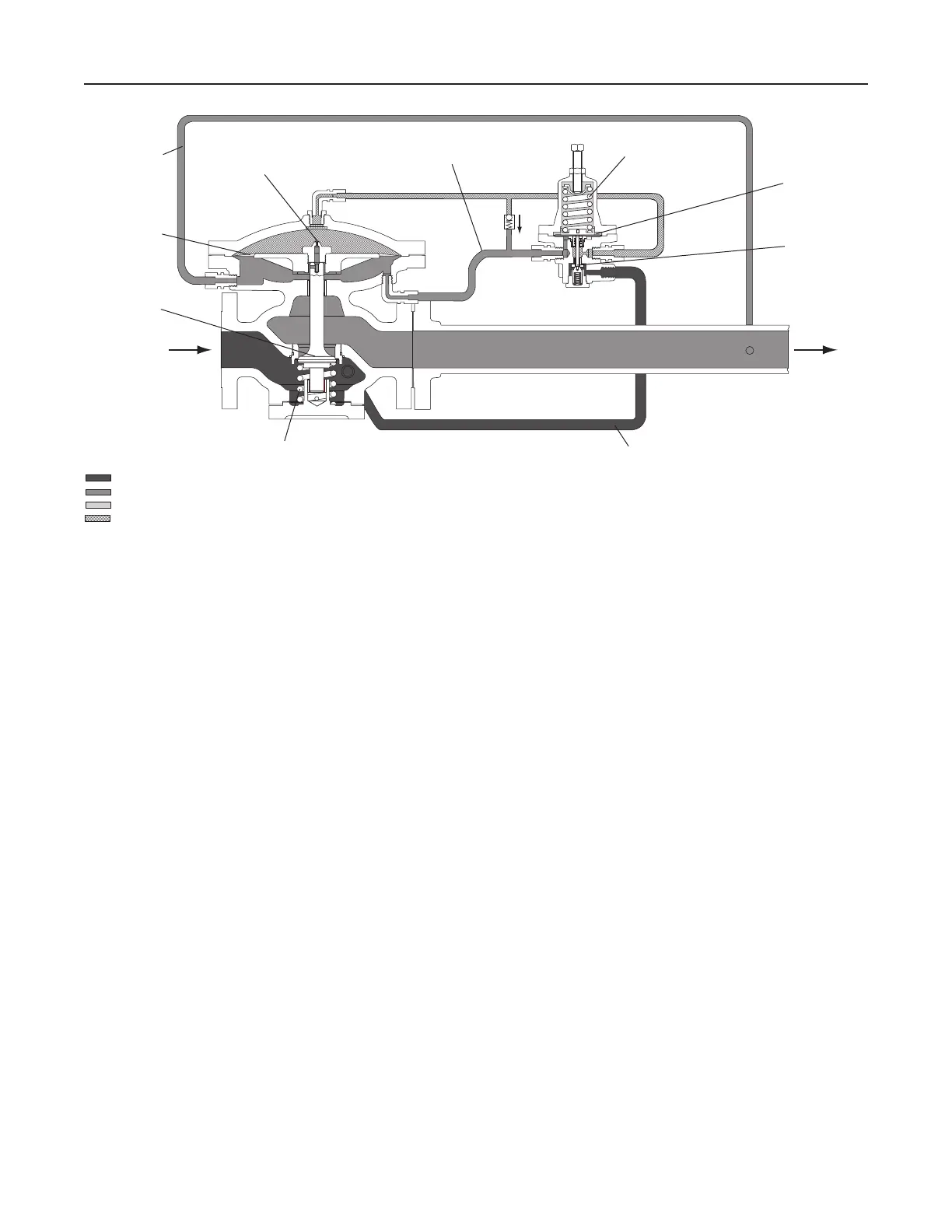

Principle of Operation

Refer to the operational schematic in Figure 2.

Compression of the pilot spring pushes the diaphragm

down and holds the pilot valve plug open. Outlet

pressure is changed by varying the amount of pilot

spring compression.

When steam enters the inlet of the valve, it also enters

the pilot supply line and ows through the open pilot

valve to the top of the main diaphragm. The force

created by this steam pressure on the diaphragm

overcomes the force of the main valve spring opening

the valve plug and allowing steam to ow downstream.

Downstream pressure registers under the main

diaphragm through the control line and tends to

balance the diaphragm. Steam from the downstream

system also registers under the pilot diaphragm

through line. Pressure forces the diaphragm upward,

permitting the pilot valve plug to move toward the

closed position. Flow of steam to the top of the main

diaphragm is thereby reduced and the pressure on

main diaphragm drops due to the bleed through the

orice. The main valve moves toward the closed

position, allowing only enough steam ow to satisfy

downstream requirements.

When steam demand increases, the downstream

pressure decreases below the setting of the pilot

spring. The pilot opens to increase the pressure on the

main diaphragm. The main valve opens to increase

the ow downstream. Conversely, if the steam demand

decreases, the downstream pressure increases and

the pilot reacts to decrease the pressure on top of

the main diaphragm. The main valve throttles toward

the closed position and the steam ow decreases.

Thus, through the combination of pilot and main valve

operation, control of the downstream steam pressure

is maintained.

A check valve is included in all Type 92B pilots to limit

dierential pressure on the main valve diaphragm.

In the event of a large decrease in downstream

pressure, the check valve opens to relieve diaphragm

loading pressure to the downstream system. The

check valve cartridge assembly has a factory setting

to limit dierential pressure across the diaphragm

to approximately 40 psid / 2.8 bar d. If diaphragm

dierential pressure exceeds 40 psid / 2.8 bar d,

the check valve opens to relieve diaphragm loading

pressure into the downstream system, thereby

preventing a high dierential across the diaphragm

which might otherwise cause diaphragm damage. The

check valve closes and normal operation resumes

when the dierential pressure across the diaphragm is

reduced to the proper level.

Figure 2. Type 92B Operational Schematic

E0672_1

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

LOADING PRESSURE

CONTROL LINE

MAIN VALVE

DIAPHRAGM

VALVE PLUG

MAIN VALVE SPRING

PILOT SUPPLY LINE

PILOT VALVE

PLUG

PILOT

DIAPHRAGM

PILOT SPRING

PILOT CONTROL LINE

ORIFICE

3

Type 92B

Loading...

Loading...