Type 6492HM Safety Override System

Refer to Figure 3. Once placed in operation, the

upstream Type 92B (B) pilot senses the intermediate

pressure between both valves, and the Type 6492HM

(A) pilot senses downstream pressure of the second

valve. As demand for ow increases, intermediate

pressure will fall causing the Type 92B pilot to open. As

the Type 92B pilot opens, loading pressure to the main

valve increases, opening the main valve.

The Type 6492HM (A) safety override pilot remains

open because its setpoint is above the setpoint of

the downstream valve. In the unlikely event that the

downstream valve fails open, downstream pressure

will rise above the downstream valve’s setpoint. This

pressure is sensed by the Type 6492HM (A) safety

override pilot. As downstream pressure increases

the Type 6492HM (A) safety override pilot closes,

reducing loading pressure to the upstream main valve,

which positions the main valve to maintain desired

downstream override pressure.

In the event that the upstream valve fails, the

downstream valve will prevent downstream pressure

from rising above safe operating levels.

It is recommended to install some type of warning

system, such as a sentinal relief valve, to warn the

operator that a valve has failed in the system. This

will prevent prolonged operation with one valve, which

could cause valve trim wear and noise associated with

operation at high dierential pressures.

Installation

!

WARNING

Regulators should be installed, operated

and maintained in accordance with

federal, state and local codes, rules and

regulations and Emerson instructions.

If the regulator vents steam or a leak

develops in the system, it indicates that

service is required.

Failure to take the regulator out of

service immediately may create a

hazardous condition.

Call a service man in case of trouble.

Only a qualied person must install or

service the regulator.

CAUTION

Be sure to install Type 92B pilot above

the pipeline with the adjusting screw

pointing up and the control line sloped

at a downward pitch to the main line to

ensure proper condensate drainage.

The following points should be kept in mind when

installing this pressure reducing valve. See Figure 4

for a schematic drawing of a typical installation.

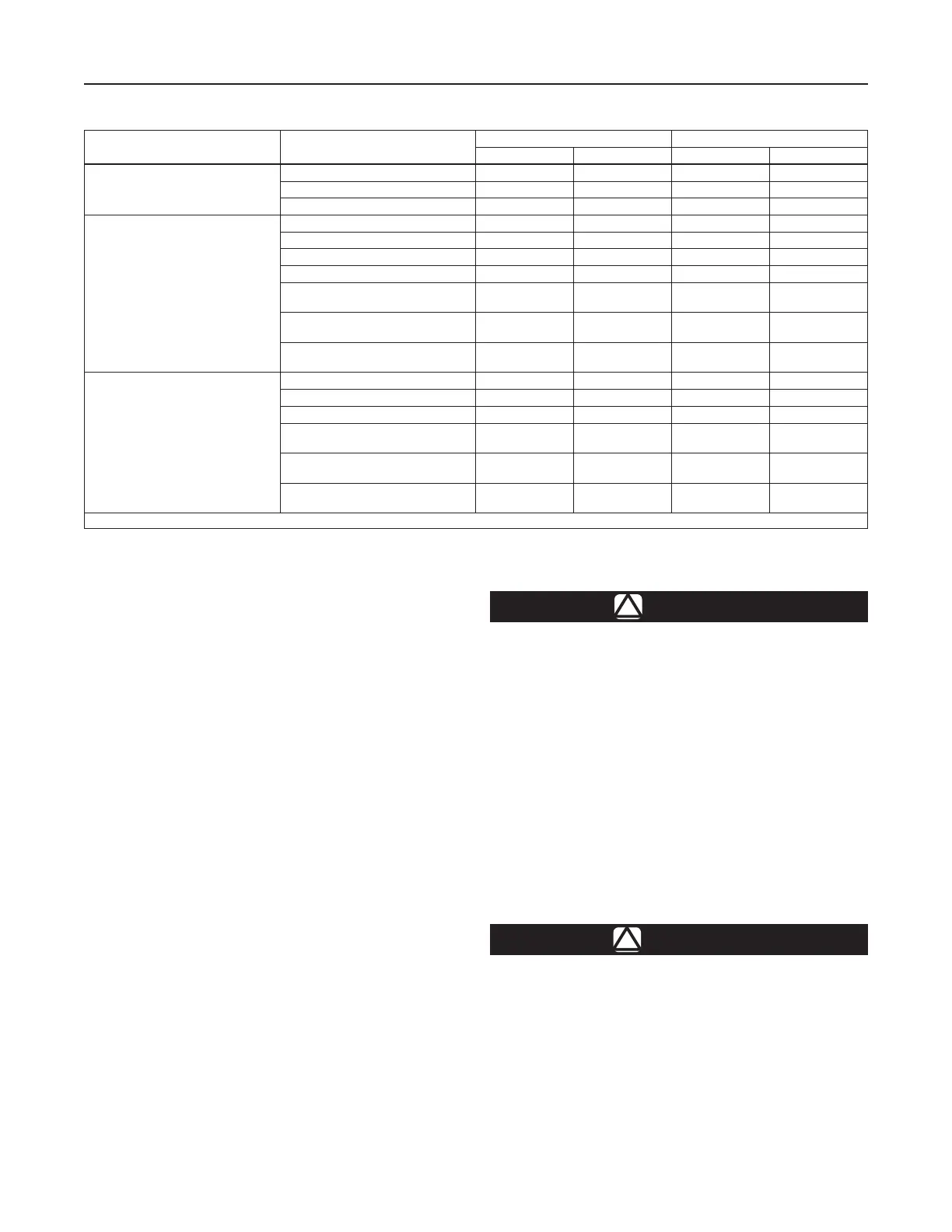

Table 3. Maximum Inlet Pressures and Temperatures

BODY MATERIAL END CONNECTION

MAXIMUM INLET PRESSURE MAXIMUM TEMPERATURE

psig bar °F °C

Cast Iron

NPT 250 17.2 406 208

CL125 FF 125 8.6 353 178

CL250 RF 250 17.2 406 208

Steel

NPT 300 20.7 450 232

SWE 300 20.7 450 232

CL150 RF 185 12.8 450 232

CL300 RF 300 20.7 600 316

(1)

PN 16/25/40 (NPS 1, 1-1/2, 2 and 3 /

DN 25, 40, 50 and 80)

300 20.7 600 316

(1)

PN 16 (NPS 4 / DN 100) 185 12.8 450 232

PN 25/40 (NPS 4 / DN 100) 300 20.7 600 316

(1)

Stainless steel

NPT 300 20.7 450 232

CL150 RF 175 12.1 450 232

CL300 RF 300 20.7 600 316

(1)

PN 16/25/40 (NPS 1, 1-1/2, 2 and 3 /

DN 25, 40, 50 and 80)

300 20.7 600 316

(1)

PN 16

(NPS 3 and 4 / DN 80 and 100)

175 12.1 450 232

PN 25/40

(NPS 3 and 4 / DN 80 and 100)

300 20.7 600 316

(1)

1. 450°F / 232°C with standard seat ring, 600°F / 316°C with seal weld option.

4

Type 92B

Loading...

Loading...