Safe Use Instructions – Emerson FloBoss 104

Part D301733X012

February 2018

www.Emerson.com/RemoteAutomation 5

Default values for all parameters exist in the firmware of

the FloBoss. If the default is acceptable for your

application, it can be left as it is. Perform adjustments to

the FloBoss through the configuration software. Refer to

the ROCLINK 800 Configuration Software User Manual (Part

D301159X012).

8. The calibration routines support 5-point calibration,

with the three mid-points calibrated in any order. The low-

end or zero reading is calibrated first, followed by the

high-end or full-scale reading. The three mid-points can

be calibrated next, if desired. The diagnostic analog

inputs—logic voltage (E1), battery voltage (E2), and

board/battery temperature (E5)—are not designed to be

calibrated.

With the optional I/O termination points installed, the

Analog Input can be calibrated using ROCLINK 800

software.

The built-in inputs that are supported with the 5-point

calibration are:

▪ Differential pressure located at AI Point A1.

▪ Static pressure located at AI Point A2.

▪ RTD temperature located at AI Point A3.

These inputs are assigned to the first three Analog Input

points. The calibration procedure for these inputs is

described in the ROCLINK 800 Configuration Software User

Manual (Part D301159X012).

9. To troubleshoot problems with the FloBoss 104,

identify whether the problem is with the configuration or

the hardware. Check the configuration in ROCLINK 800

software to identify any incorrect settings. Inspect the

hardware for damage. Inspect the termination boards for

connection location errors.

If you are experiencing problems with the FloBoss 104 that

appear to be software related, try resetting the FloBoss

with a warm start, a cold start, or a jumper reset.

If you are experiencing problems that appear to be

hardware-related, verify the wiring. If you still experience

problems, contact your local sales office for return

authorization.

During operation, the FloBoss 104 can be monitored (to

view or retrieve current and historical data) either locally

or remotely. Local monitoring is accomplished either by

viewing the LCD panel detailed in Section 2, or by using

ROCLINK 800 software on a PC connected through the LOI

port. Remote monitoring is performed through Comm 1

or Comm 2 of the FloBoss using ROCLINK 800 software, or

host system. Refer to Figure 8 for the communication

terminations.

10. To remove the FloBoss 104 from operation.

disconnect power from the unit and then remove all

external wiring connections. Remove the gas lines. Finally

remove the FloBoss housing from the pipestand or orifice

plate. The FloBoss may be placed in a box for

transportation.

DANGER

Take care when removing gas lines from the FB104.

Use one wrench to prevent the sensor connector from

moving, and use a second wrench to disconnect the

gas line. Allowing the sensor to rotate will damage the

internal wiring.

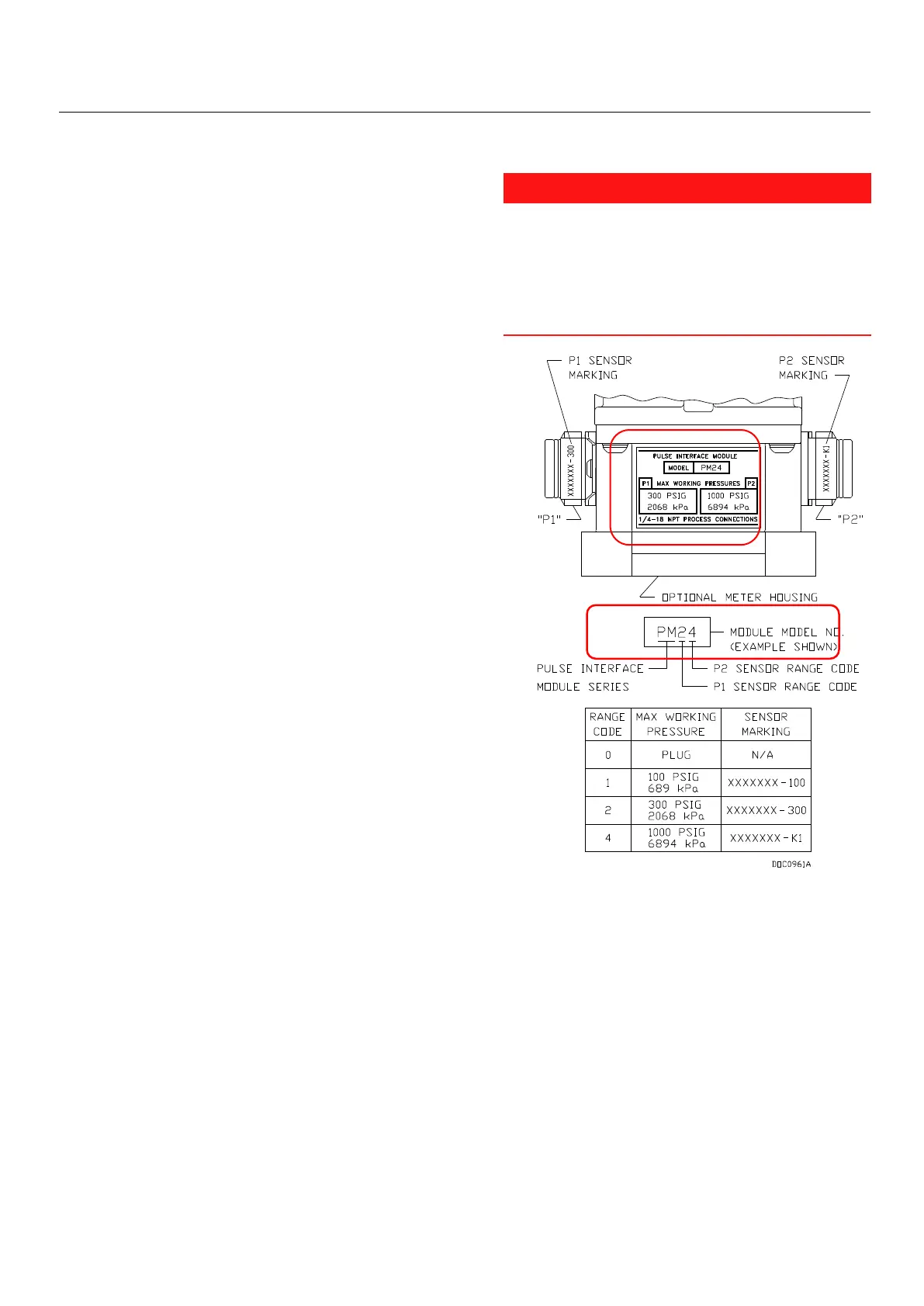

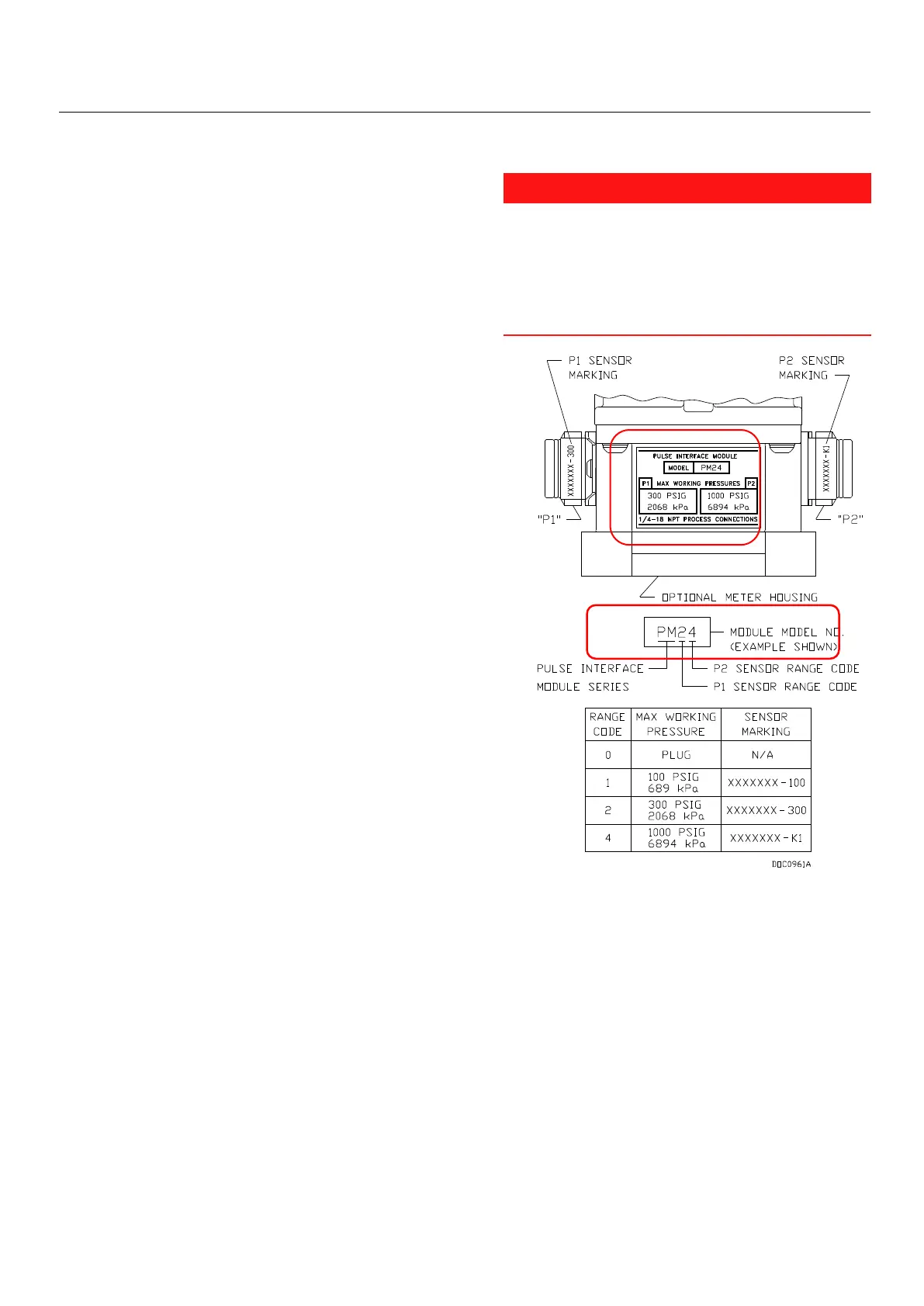

Figure 7. FB104 Pulse Interface Housing

When connecting gas pressure lines to the optional

Pulse Interface module, note the maximum working

pressure limits to the individual P1 and P2 sensors

based on the model number of the module. For

example, Figure 7 shows a model PM24 module with

its P1 (300 PSIG/2068 kPa) and P2 (1000 PSIG/6894

kPa) sensor ranges.

Loading...

Loading...