Do you have a question about the Emerson Daniel 3410 Series and is the answer not in the manual?

Initial setup steps and required information for meter startup.

Overview of software utilities for meter configuration, testing, and data management.

Configuration parameters for connecting via Modbus serial interface.

Explanation of HART communication for digital signal transmission.

Instructions for integrating meters with DeltaV System communications.

Introduction to advanced features requiring optional software keys for enablement.

Procedure for obtaining and applying software keys to enable optional features.

Explanation of terms related to transducer timing for batch data and calculations.

How ultrasonic signals are processed to ensure accurate transit time measurement.

Explanation of raw, flow-condition, and base-condition volumetric flow rate values.

Overview of calculated flow characteristics like symmetry and turbulence.

Description of dry and wet calibration steps for meter accuracy.

Guide for calibrating analog inputs and outputs using the Analog Inputs Wizard.

Process for calibrating meter factors based on flow conditions.

How to test frequency, current, and digital outputs by forcing them to specific values.

Configuration of HART outputs including dynamic variables and device identification.

Setup for polling GC data for gas property calculations.

How to set up parameters for the meter's local display.

Explanation of data point actions for daily and hourly logs.

How the meter monitors data points and logs alarm status changes.

Utilities for managing meter configurations, including viewing, editing, and comparing.

Feature to view transducer waveforms for diagnostic analysis in time and frequency domains.

Utility to calculate Speed of Sound for gas compositions and operating conditions.

Instructions for upgrading meter firmware and software components.

Table of conversion factors for metric and U.S. Customary units used in the manual.

Formulas for K-Factor and Inverse K-Factor calculations.

Calculation method for the chord "L" dimension using meter housing and transducer dimensions.

Solutions for common Ethernet communication issues with the meter.

Troubleshooting guidance for mechanical and electrical issues encountered with the flow meter.

Tables providing flow rate data based on PSIG and m/s or ft/s.

Table listing configuration parameters protected from changes when the CPU Board WRITE PROT. switch is ON.

Alphabetical listing of topics and their corresponding page numbers for easy reference.

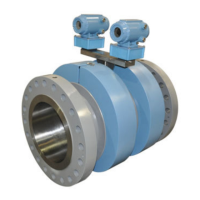

| Meter Body Material | Stainless Steel |

|---|---|

| Transmitter Housing Material | Stainless Steel |

| Process Temperature Range | -40°C to 204°C (-40°F to 400°F) |

| Output Signal | 4-20 mA |

| Process Connection | Flanged, Wafer, Threaded |

| Certifications | CSA, ATEX, IECEx |

| Operating Temperature | -40 to 185 °F (-40 to 85 °C) |

| Enclosure Rating | NEMA 4X |

| Material | Stainless Steel |