142 Micro Motion Series 1000 and Series 2000 Transmitters

Troubleshooting

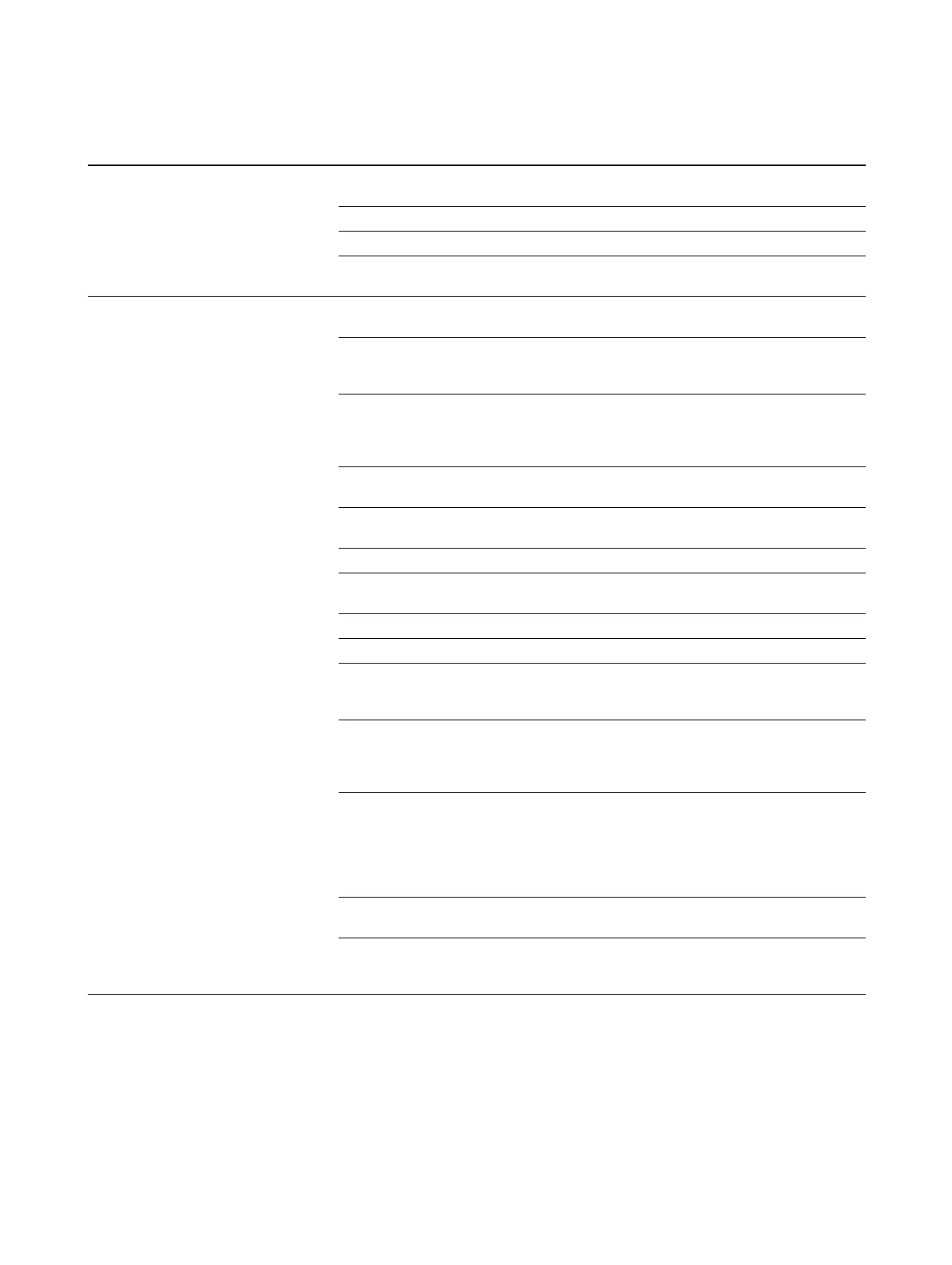

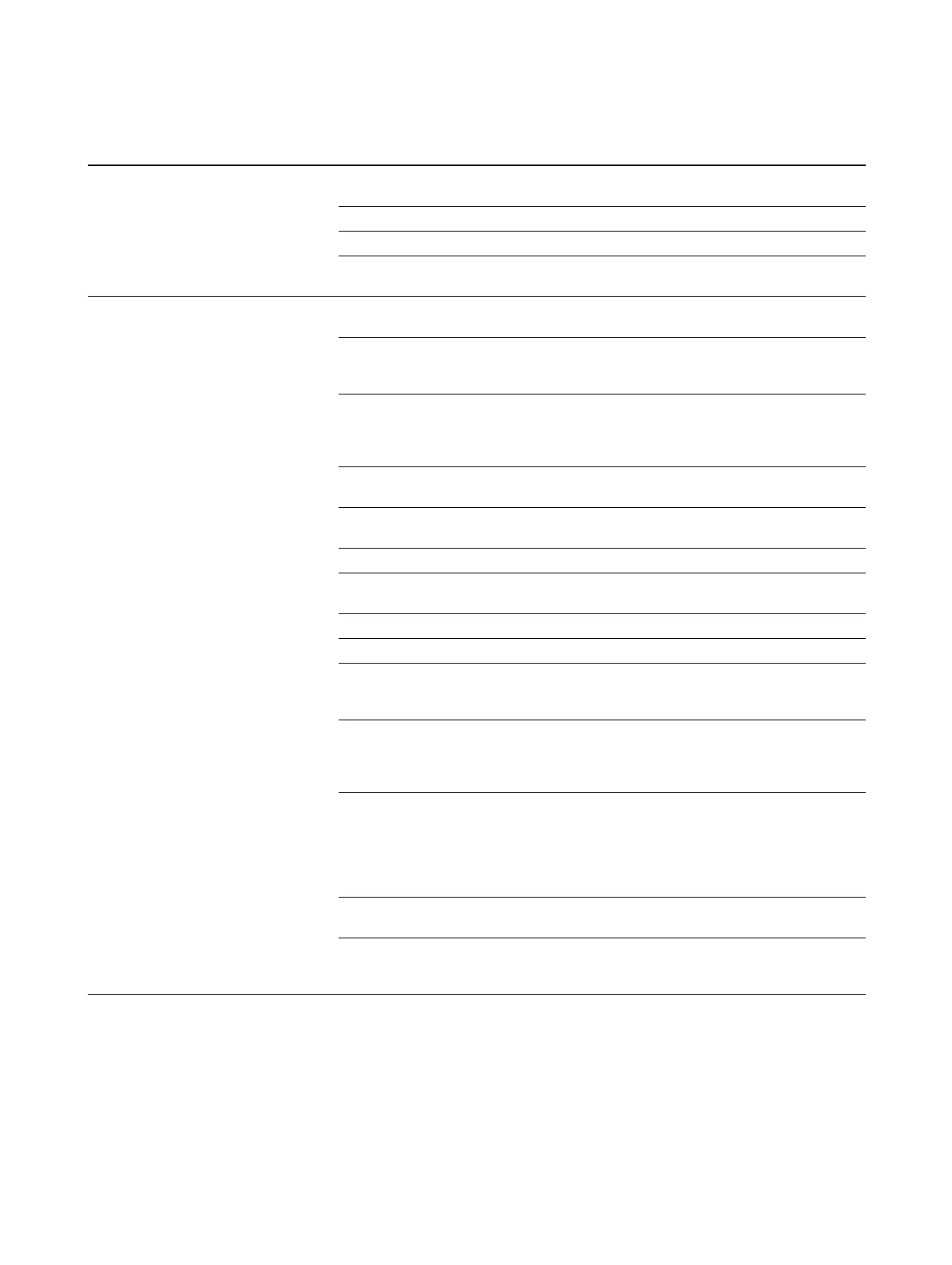

Table 12-6 Process variables problems and possible remedies

Symptom Cause Possible remedy

Steady non-zero flow rate under

no-flow conditions

Misaligned piping (especially in new

installations)

Correct the piping.

Open or leaking valve Check or correct the valve mechanism.

Bad sensor zero Rezero the meter. See Section 5.5.

Bad flow calibration factor Verify characterization. See

Section 6.2.

Erratic non-zero flow rate under

no-flow conditions

RF interference Check environment for RF interference.

See Section 12.14.4.

Wiring problem Verify all sensor-to-transmitter wiring

and ensure the wires are making good

contact.

Incorrectly grounded 9-wire cable (in

9-wire remote installations and remote

core processor with remote transmitter

installations)

Verify 9-wire cable installation. Refer to

Appendix B for diagrams, and see the

installation manual for your transmitter.

Vibration in pipeline at rate close to

sensor tube frequency

Check environment and remove source

of vibration.

Improper sensor grounding (T-Series

sensors only)

Verify that the sensor is grounded to

earth ground.

Leaking valve or seal Check pipeline.

Inappropriate measurement unit Check configuration. See

Section 12.20.

Inappropriate damping value Check damping configuration.

Slug flow See Section 12.17.

Plugged flow tube Check drive gain and tube frequency.

Purge the flow tubes or replace the

sensor.

Moisture in sensor junction box Open junction box and allow it to dry.

Do not use contact cleaner. When

closing, ensure integrity of gaskets and

O-rings, and grease all O-rings.

Mounting stress on sensor Check sensor mounting. Ensure:

• Sensor is not being used to support

pipe.

• Sensor is not being used to correct

pipe misalignment.

• Sensor is not too heavy for pipe.

Sensor cross-talk Check environment for sensor with

similar (±0.5 Hz) tube frequency.

Incorrect sensor orientation Sensor orientation must be appropriate

to process fluid. See the installation

manual for your sensor.

Loading...

Loading...