Do you have a question about the Emerson Rosemount 470XA and is the answer not in the manual?

Emerson's warranty for firmware, goods, and services, including exclusions and limitations.

Outlines remedies for warranty breach and limits seller's liability for damages.

Ensures safe installation and operation according to requirements.

Warnings about electric shock and explosion risks.

Guidance on ventilation and leak testing procedures.

Safety measures for toxic vapors and hot surfaces.

Warnings on moving the heavy device and securing physical access.

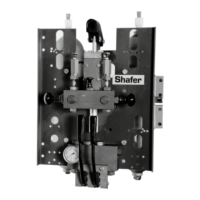

Overview of the Rosemount 470XA GC and its Maintainable Module technology.

Details on electronics, construction, and performance specifications.

Information on Ethernet, analog, and digital interfaces.

Capabilities for storing analysis results, chromatograms, and logs.

Details on vent flow rates and reference to product certifications.

Description of external components and views: front, left, right, rear.

Diagram and labels for the left side of the GC.

Diagrams and labels for the right and rear views of the GC.

Diagram and labels for the LOI keypad and screen.

Description of the backplane board and its connections.

Details on chromatography columns, valves, and detectors.

Considerations for choosing an installation site, including temperature and access.

Procedure for unpacking and inspecting the gas chromatograph upon receipt.

Steps to check shipment completeness and inspect for damage.

Options for mounting the GC: wall mount or pole mount.

Diagram showing the physical dimensions of the Rosemount 470XA.

Instructions and dimensions for pole mounting the GC.

Instructions and parts for wall mounting the GC.

Information on SCS options and requirements.

Procedure for mounting a single-stream SCS to the GC.

Steps to securely attach the GC to its mounting bracket.

Procedure for connecting tubing and atmospheric vents.

Specifications and procedures for carrier gas connection.

Specifications and procedures for actuation gas connection.

Requirements for calibration gas quality and connection.

Basic principles of sample handling for GC analysis.

Recommendations for sample lines, filters, regulators, and valving.

Information on GC cable entries and wiring.

Description of terminal boards for inputs and outputs.

Description of GC Ethernet ports and configuration.

Using Ethernet 1 for local computer connection.

Using Ethernet 2 for supervisory system connection.

Procedure for connecting a PC directly to the GC's Ethernet port.

Connecting digital and analog devices to the GC.

Details on configuring digital inputs and outputs.

Wiring procedures for analog input signals.

Configuration of analog outputs for transmitting GC variables.

Instructions for connecting the 24 Vdc power source.

General precautions for grounding electrical and signal lines.

Procedures for applying gases and initial setup.

Procedure for applying calibration gas.

Steps for powering on the GC for the first time.

Checking and acknowledging alarms after initial power-up.

Step-by-step guide for initial GC configuration.

Connecting a PC to the GC via Ethernet 1 port.

Navigating the GC's Local Operator Interface.

How to navigate menus and screens on the LOI.

Procedures for entering data using the LOI keypad.

Overview of LOI screens like Alarms and Reports.

Accessing and viewing live and archived chromatograms.

Details on Heaters and Status Display screens.

Controlling and monitoring valve modes and status.

Display and adjustment of carrier pressure.

Configuring discrete input settings.

Configuring discrete output settings.

Configuring analog input signals.

Configuring analog output signals.

System information and component data table details.

Setting timed events and calculation parameters.

Configuring streams and communication settings.

Accessing Alarm, Event, and Maintenance logs.

Starting sequences, halting, and calibrating the GC.

Adjusting screen brightness and setting GC time.

Setting up serial port parameters for Modbus communication.

Procedure for setting the GC's date and time.

Entering calibration gas concentration data.

Step-by-step guide for initial GC calibration.

Configuring Ethernet port settings.

Procedures for acknowledging alarms.

Acknowledging and clearing all active alarms.

Accessing maintenance and event log entries.

Methods for viewing live chromatogram data.

Procedure for viewing saved chromatograms.

Procedure for starting a single stream analysis run.

Procedure for starting a calibration analysis run.

Topics including validation, calibration gas change, and AVT.

Configuring streams and parameters for validation.

Initiating validation cycles and generating reports.

Procedure for changing the calibration gas cylinder.

Explanation of AVT for optimizing valve timing.

Description of Warm-start and Maintenance modes.

How to initiate AVT adjustments.

Using the Cal-Gas Saver feature to reduce gas consumption.

Procedure when installing a new module or changing the CPU board.

Recommendation to periodically save diagnostic data.

Configuring the GC for daily auto-calibration.

Plotting and viewing trend graphs of GC data.

Related information on configuring valve timing.

Tools and procedure for removing the maintainable module.

Prerequisites and procedure for installing the maintainable module.

List of tools for performing valve repair and maintenance.

Procedure for overhauling a valve, including diaphragm replacement.

Procedure for replacing oven system and stream switching solenoids.

Descriptions and recommended actions for common GC alarms.

Troubleshooting steps for the heater out of range alarm.

Troubleshooting for detector scaling factor and carrier pressure alarms.

Troubleshooting for stream validation, RF deviation, and calibration alarms.

Troubleshooting for LOI communication and AVT failure alarms.

Troubleshooting for module communication and validation issues.

Troubleshooting for IMB incompatibility and missing component data.

Troubleshooting for energy value and stream order alarms.

Troubleshooting for data integrity and n-pentane retention time drift.

Troubleshooting ethane drift and GC power-up problems.

Troubleshooting steps for un-normalized total errors.

Procedure for replacing the GC's CPU board.

Procedure for recovering the CPU if it is suspected to be corrupt.

Lists of available spare parts for helium and hydrogen carrier configurations.

| Manufacturer | Emerson |

|---|---|

| Model | Rosemount 470XA |

| Category | Industrial Equipment |

| Wireless Standard | WirelessHART |

| Power Supply | 24 VDC |

| Output | WirelessHART |

| Mounting | Wall or pipe mount |

| Hazardous Area Approvals | ATEX, IECEx, FM, CSA |

| Enclosure Rating | IP66/NEMA 4X |

| Material | 316L Stainless Steel |

| Communication Protocol | WirelessHART |