8

REFRIGERANT PIPING

Tubing specifi cations

System supports refrigerant runs to internal. See Table 2,

Page 8. Units furnished with sweat connections, equipped

with refrigerant valves and Schrader fi ttings for charging

and taking pressure readings.

NOTICE

Install fi lter drier in liquid line at outdoor unit on all

models.

Table 2 - S1CV/S1HV Tubing Specifi cations

Model

Max.

Length

Equivalent

Feet

Max.

Lift

Max.

Trap

Height

Liquid

Line

Suction

Line

“H” “P” O.D. O.D.

09

100’

(30 m)

35’

(11 m)

20’

(6 m)

1/4" 1/2"

12 1/4" 1/2"

18 3/8" * 5/8"

24 3/8" * 5/8"

*Install 3/4” to 5/8” Bushing @ Air Handler

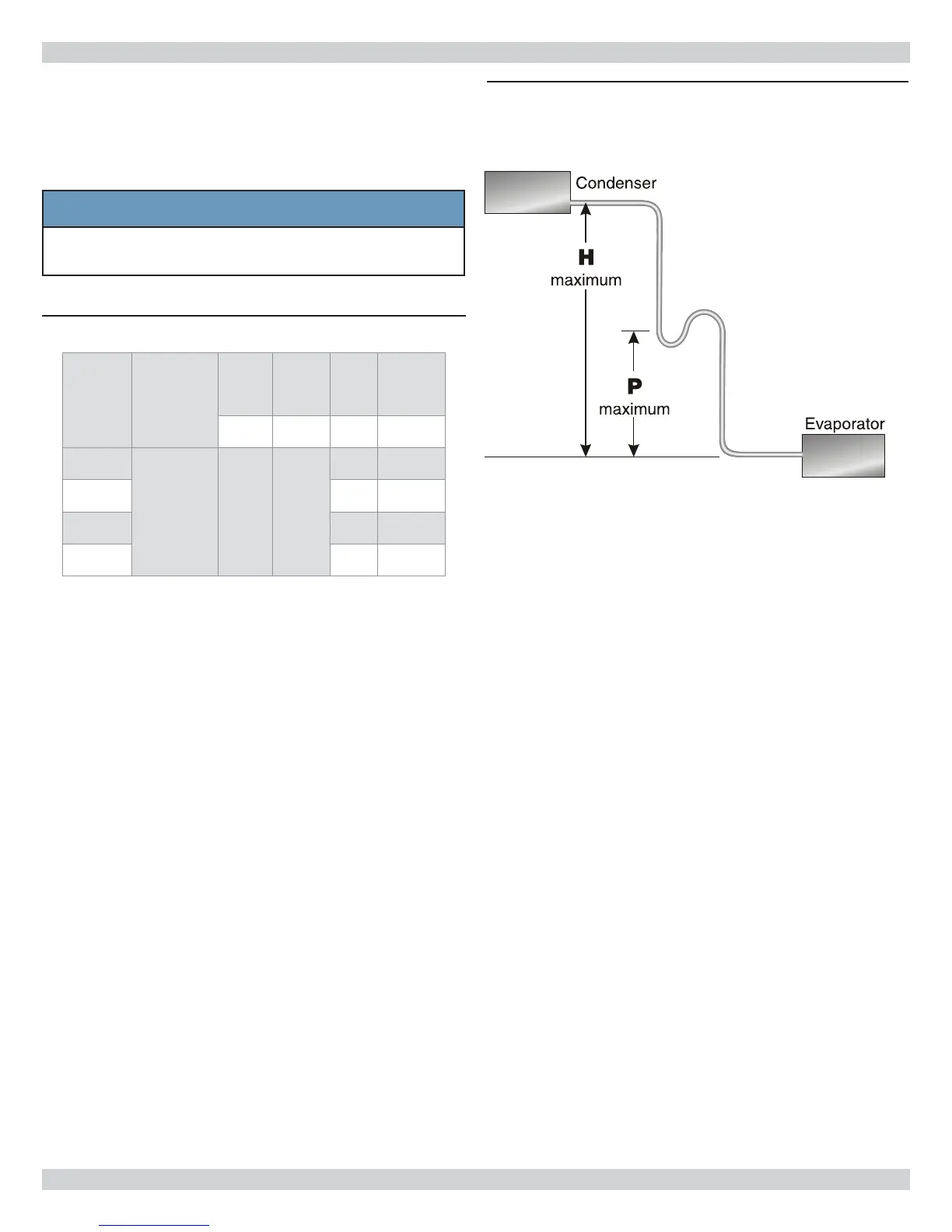

P-Trap Installation

• Recommend a P-trap when suction riser P is equal to

or greater than that shown in Figure 3 and Table 2 .

• Condenser installed above air handler, P-trap is

required. Facilitates return of oil back to compressor.

Locate trap at midpoint of rise

• Fabricate P-trap using 2 street elbows and 2 regular

elbows.

Or

• Purchase prefabricated trap from wholesaler or

distributor. Trap should be shallow as with 3 elbow

confi guration.

• Each elbow is approximately two (2) equivalent feet.

• One P-trap is equal to approximately 12 equivalent

feet.

• P-traps are not required at foot of hot gas risers due to

increased oil fl ow at higher temperatures.

Figure 3 - P-Trap Placement

(See Table 2 for Dimensions H & P)

Loading...

Loading...