9

REFRIGERANT PIPING

Refrigerant Piping

1.

Clean ends of tubing and insert into fi ttings. See

Figure 4.

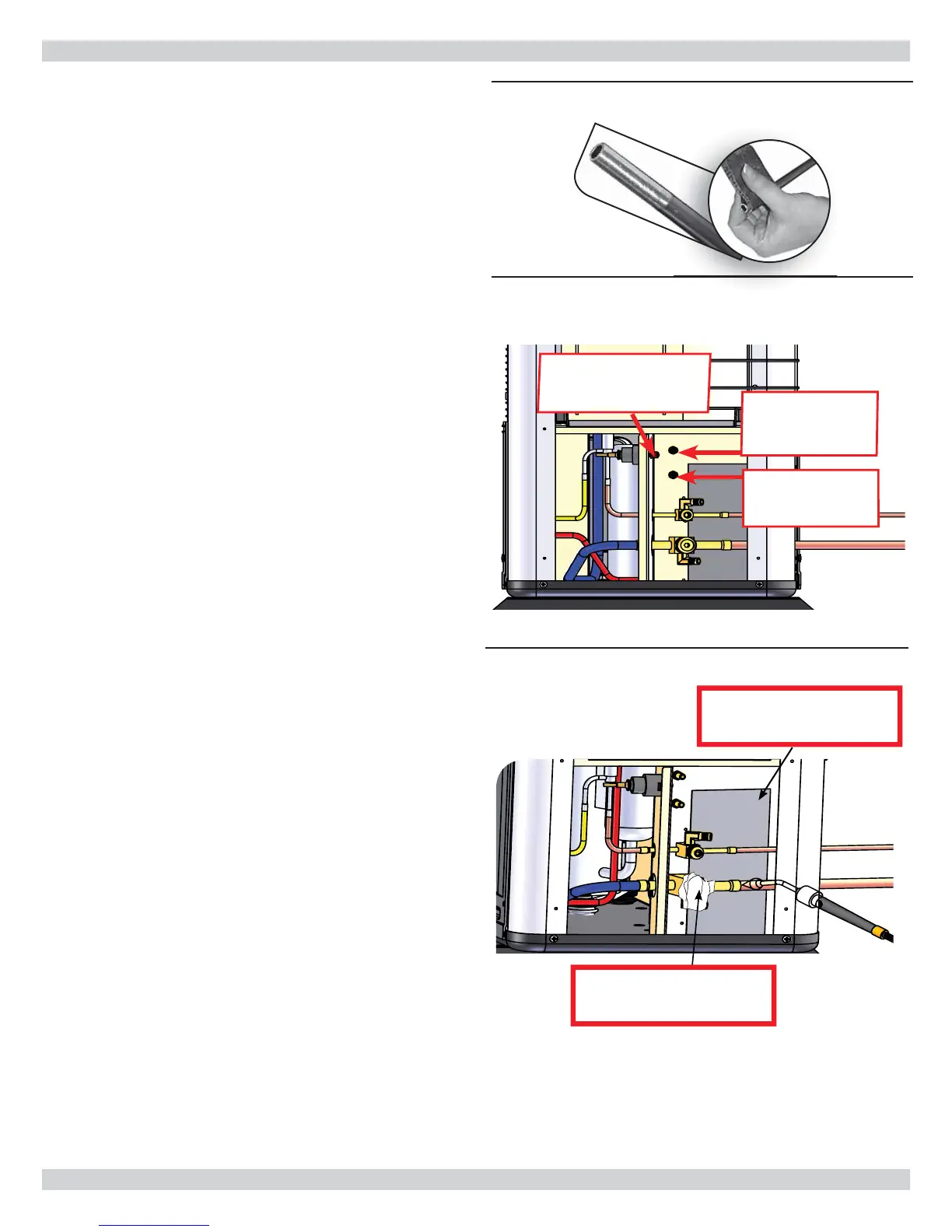

2.

Protect valves by wrapping with wet rag “heat sink”

before brazing. See Figure 6 .

3.

Use shield to protect paint as shown in Figure 5. (Shield

can be made from scrap metal.)

4.

Braze tubing into fi ttings.

Figure 4 - Clean Ends Of Tubing

Figure 5 - Common Suction, Common Discharge,

& High Pressure Switch

Piping Preparation

• Avoid piping on wet and rainy days.

• Use only clean, refrigeration-grade copper tubing.

• Use tubing benders to guard against kinking.

• Verify no burrs remain on fi ttings.

• Cap ends of lines until ready for connections. Verify

plastic end caps remain in place when inserting through

wall openings.

• Insulate both lines.

• Isolate tubing from transmitting vibration to building or

unit and avoid contact with sharp edges.

• Wrap refrigeration valves with wet rag “heat sink” to

protect valves while brazing. (See Figure 31, Page 51.)

COMMON

DISCHARGE

PORT

HIGH PRESSURE

SWITCH

COMMON

SUCTION

PORT

ADD Heat Shield behind

Valve when brazing to

prevent damage to unit

ADD Wet Rag over Valve to

Keep from melting internal

valve Components

Figure 6 - Wet Rag, Heat Shield Over Valves

Loading...

Loading...