Routine Maintenance/Service Tool

© 2017 EMP, Inc. 17

Routine Maintenance

When checking/filling vehicle

fluids

Ensure fluid levels are correct. Low fluid can cause a pump seal failure.

Every engine oil change or every

three months, whichever is

shorter

Inspect cooling system for leaks. Sample coolant and check to ensure coolant

meets minimum coolant quality requirements. Before removing the pump, evaluate

the leak using the methods outlined in the physical inspection of this document.

Every three months or more

often if conditions are harsh*

Visually inspect exterior of pump and ensure weep holes are not clogged by debris.

Check wires for wear or frayed insulation. Ensure all electrical connections are

tight.

Ensure connections are tightened to proper torque rating. Ensure all wires and pin

connections are intact. Inspect support structure for any damage or loose

hardware.

+ Inspections should also be conducted after any service to the unit.

Physical Inspection

CAUTION: Do not run the pump without fluid present. If run dry even for a short period the seal will

be damaged.

CAUTION: Pump may start running upon connection of power, ground and ignition. Do not make

electrical connections until pump and system are filled with fluid.

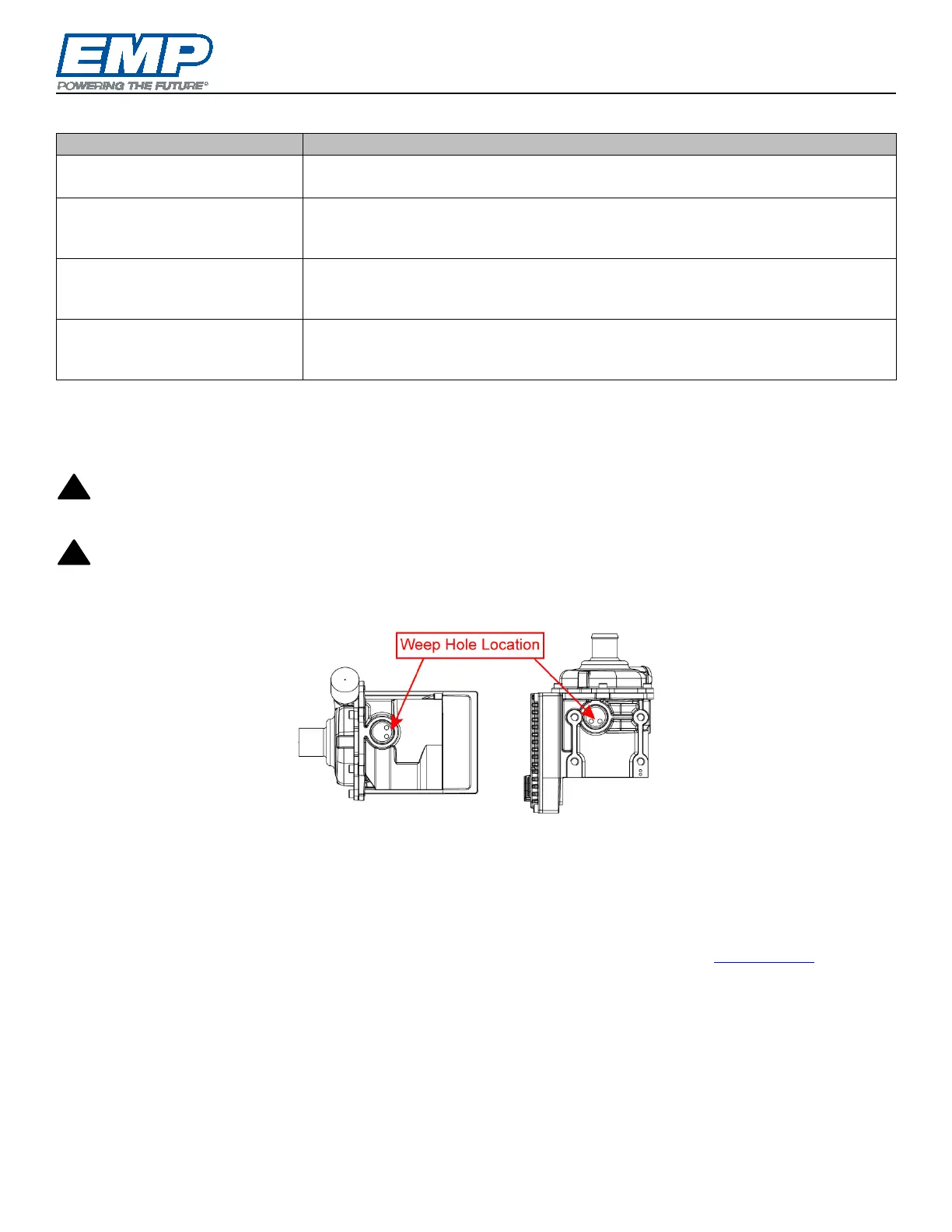

1. Make sure the weep hole ports are not clogged with debris. If weep holes are plugged then open them up.

Weep Hole Ports

NOTE: Images do not represent acceptable mounting positions. They are for reference only.

EMPower Connect™ Service Tool

Monitoring operation and manual control of the pump can be accomplished using the service tool EMPower

Connect service tool which is part of the EMP Service Suite available at no cost on the EMP website

.

To use EMPower Connect service tool, download and install the Service Suite software on a Windows PC. An

interface device will be needed between the computer and the pump. If the pump is being run without J1939

CAN, use an interface cable from the 6 pin Deutsch connector on the pump and an EMP USB/TTL converter.

The harness and converter are available as a kit (P/N 7500038001). If the pump is on a J1939 CAN bus EMPower

Connect service tool can be connected using an RP1210 compatible Data Link Adapter (DLA) to interface to the

CAN bus.

Loading...

Loading...