User’s Manual for Advanced Axial Flux Synchronous Motors and Generators

www.emrax.com Version 4.5 / January 2017 50

protected from these objects even when it is already mounted in the system (especially if the motors are mounted

close to the ground and if there are iron particles). In this case the motor should be protected with some fine net in

order for the cooling to remain sufficient at the same time! In the event a foreign object enters the motor, do not by

any means simply keep on using the drive! In this case contact the EMRAX Company and explain what happened.

Unintended handling leads to secondary damages. Opening or disassembling of the motor causes a void of warranty!

Also for opening the motor, special tools are needed to prevent any damages to the motor and to the person who

opens the motor. Opening of the motor must be avoided in any case. The EMRAX Company can remove the foreign

object from the motor and also checks the interior of the motor at the same time as well as protects it again. Removing

particles from the motor, inspection and protection of the stator costs approximately 190 euros per motor. The

customer also has to pay shipping costs and duty costs that may incur.

In case of damage, ship the drive back to the EMRAX Company for repairs. It is important, that you contact the EMRAX

Company before sending the motor back.

Keep magnetic memory cards or electronic devices out of the rotor’s close range, because the alternating magnetic field

can cause a delete of data. Be careful with medical devices (e.g. pacemakers) which are sensitive to alternating

magnetic fields.

19. Starting EMRAX motor (connecting the motor with controller):

1. Firstly, it is important to read the manuals for the EMRAX motors and for the controllers!

2. Be aware of the following safety instructions before starting:

It is essential to permanently check the loads driven by the motor for damages, cracks etc. The use of damaged

loads can lead to heaviest injuries.

The frequency converter needs to be mounted jacked up, so that a vibration free use is unconditionally

guaranteed. If this is not the case, vibrations can cause contact faults and furthermore the breakdown of

devices. This may lead to damages to the electronic system or to components in its environment.

3. Connecting the EMRAX motor, controller and batteries:

Before starting, the right direction of rotation has to be checked and if necessary changed – motor connectors

UVW must be set according to the controller phase positions. UVW (1, 2, and 3) connectors of the motor are

parallel to UVW output phases from the controller. If sensor (encoder / resolver / hall) is used it has to be

properly connected to the controller. Instructions can be provided by the sensor producer or the controller

producer. For connecting instructions of the RLS encoder / LTN resolver / hall sensors please contact the

EMRAX Company.

The drive should be, if possible, directly connected to the frequency controller, without any inserted

connectors. If this is not possible, only use high current capable, low-impedance, best quality connectors.

Shoddy connectors lead to voltage peaks and can destroy the frequency converter. Oftentimes unplugging the

connector can cause contact problems which may also lead to a destruction of the converter. We also

recommend a main vacuum switch between the batteries and controller and a suitable DC fuse.

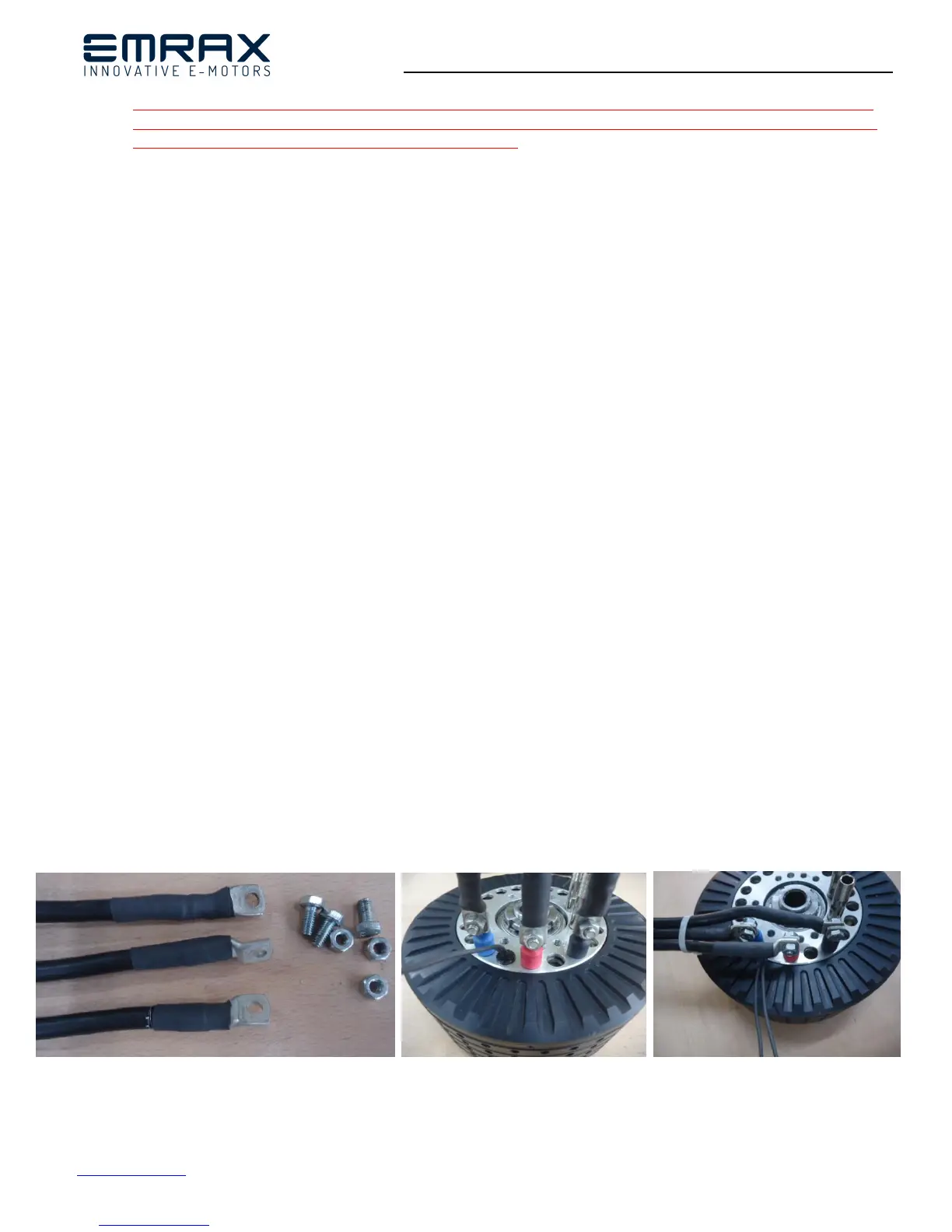

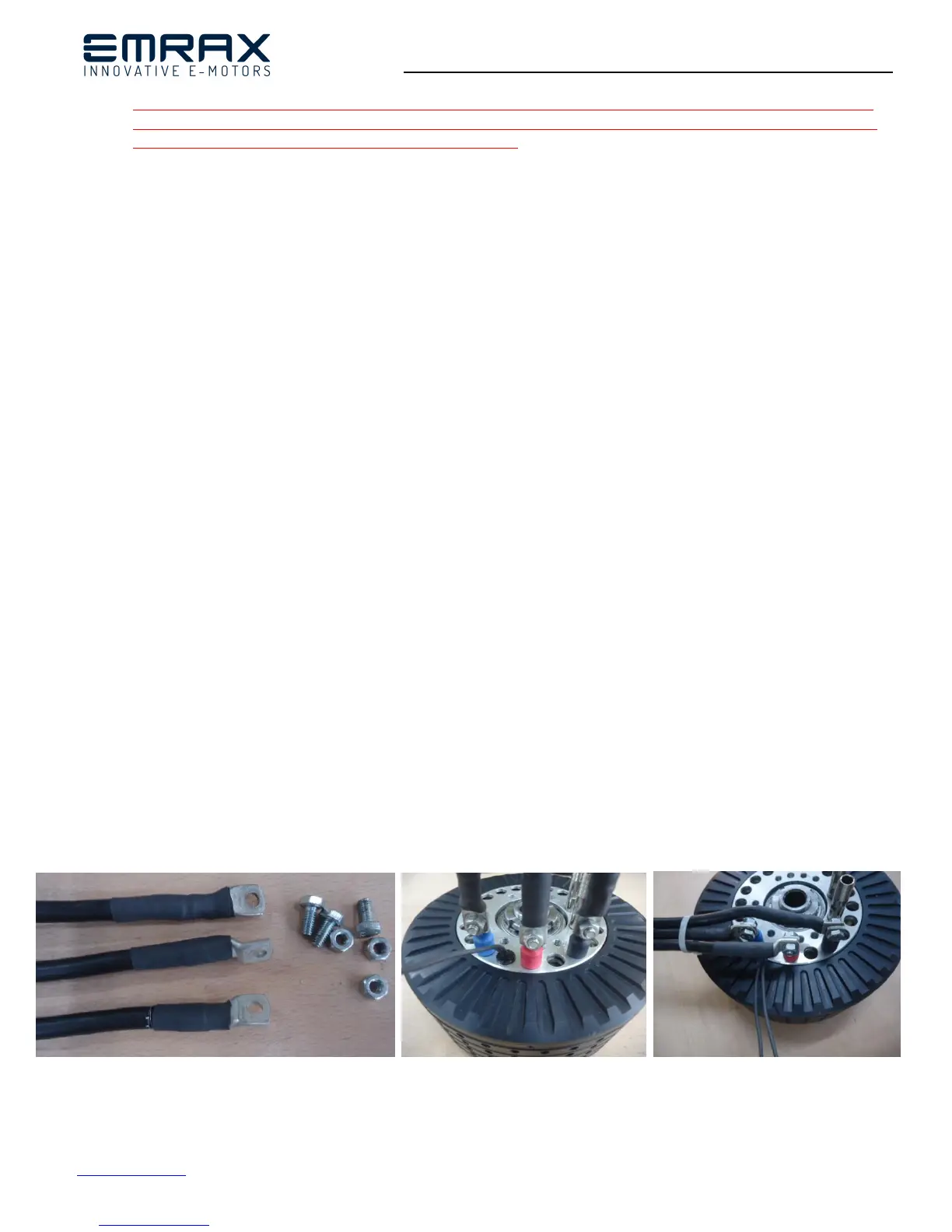

Figure 45: Straight connection of motor phase connectors to controller cables.

Loading...

Loading...