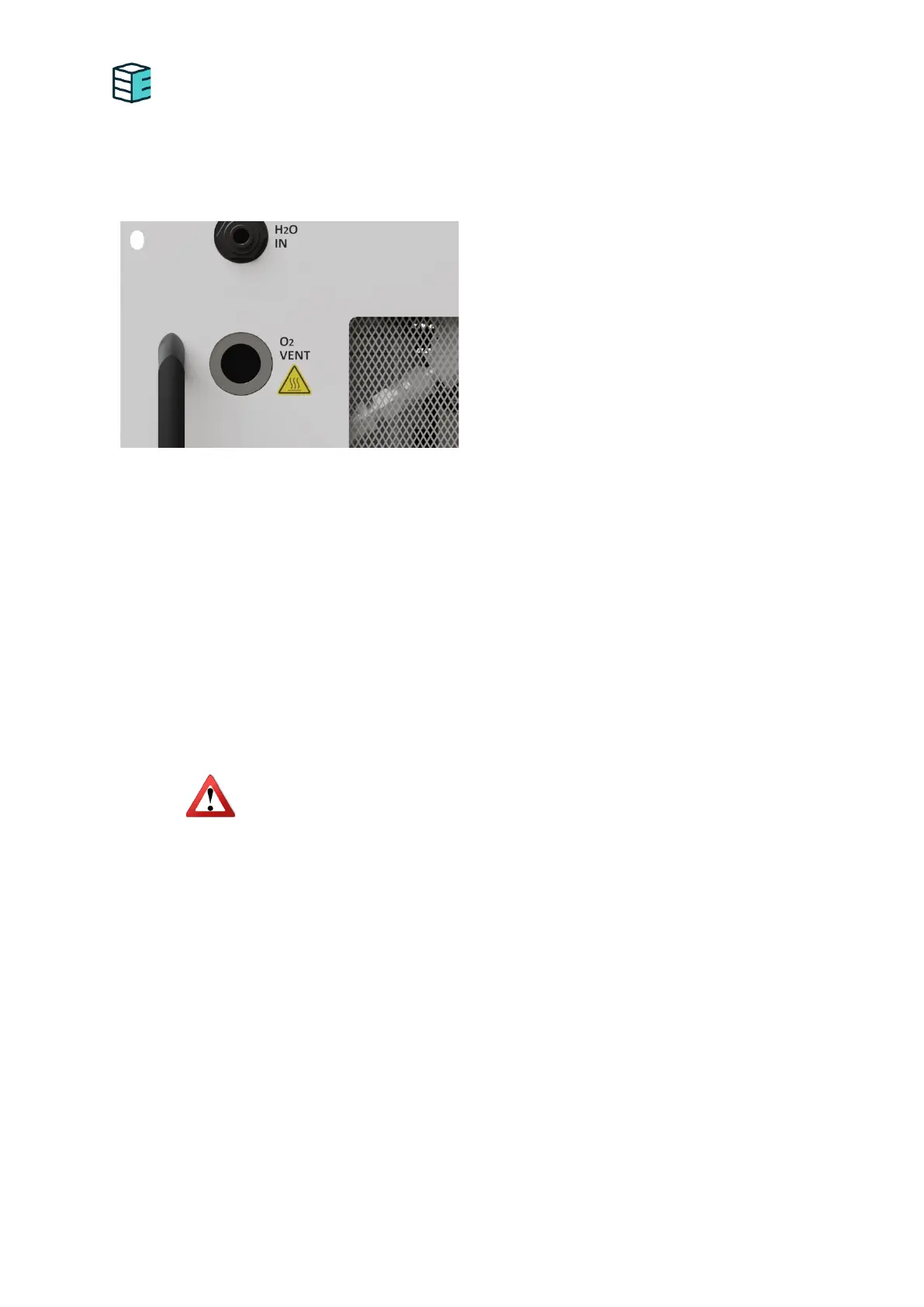

The O

2

vent line requires the most

demanding line management. Please study

this section carefully. The oxygen vent line

carries around 0.25 Nm³/h of oxygen at up

to 225 °C out of the electrolyser. Additional

components are water vapour and a

maximum concentration of 2 % vol

hydrogen. The water vapour sums up to

around 10-38 g/h.

Caution! Never mix the output of the H2 vent line with the output of the O2 vent

line.

Do not combine the O2 vent line of the EL4.0 with the O2 vent line of older

models. This line contains hot gases! Handle the output and the pipe with care,

use insulation if necessary and do not touch it during or directly after operation

as the pipe itself, connected parts and the gases at the outlet are hot and can

create injuries and damages.

Make sure, that there is never building up overpressure or underpressure of more

than 0.2 barg inside the pipe and that it is always at atmospheric pressure!

Otherwise, the device will get permanently damaged.

The line contains water steam and liquid water which is able to freeze and block

the pipe. The pipe of each device and the common pipes for several devices must

be sized appropriately and managed with water traps, heater and good

engineering practices to always allow bidirectional gas exchanges while still

draining the water safely.

The operator must ensure that the outlet satisfies all relevant local safety

guidelines, rules, directives and regulations, in terms of the safe dispersion of the

vented gas, noise emission, risk assessments, maintenance, a satisfactory safety

concept being utilised, and all other relevant areas.

It is the operator’s responsibility to regularly check and maintain all pipes.

Enapter is not responsible for any damage caused to the device from mismanaged

piping arrangements.

To connect the port labelled “O

2

Vent”, use heat and KOH resistant pipes, sealings and connectors only.

If connecting several devices to a common vent line, make sure the diameter of the line is sufficient

Loading...

Loading...