Liquiphant S, Nivotester

4 Endress+Hauser

General information

!

Note!

General information on functional safety (SIL) is available at:

www.de.endress.com/SIL (German) or www.endress.com/SIL (English) and in the Competence Brochure

CP002Z "Functional Safety in the Process Industry - Risk Reduction with Safety Instrumented Systems".

Measuring system design

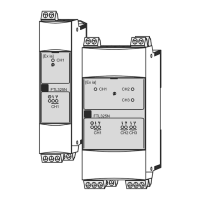

System components The measuring system's devices are displayed in the following diagram.

SD175en02

The measuring system consists of the Liquiphant S FDL60 or FDL61 sensor with the FEL67 electronic insert

and Nivotester FTL670 switching unit.

A signal which is dependent on the level is generated in the sensor. This is fed to the switching unit where it

is made available as a fail-safe contact.

Description of use as a

protective system

The tuning fork of the sensor vibrates at its intrinsic resonance frequency. The frequency decreases if the fork

is submersed in liquid. This change in frequency causes the fail-safe contact to change.

The switch point depends on installation. For information on the switch point, please refer to the Operating

Instructions (→ ä 6, "Supplementary device documentation").

SD175en03

1. Installation from above

2. Installation from the side

"

Caution!

The measuring line only works in the overfill protection safety function (MAX safety) using the fail-safe contact!

The fail-safe contact always works in idle current safety; i.e. the contact opens when:

• The switch point is exceeded (level exceeds response height)

• A fault occurs

• The mains voltage fails

FTL670

s

Nivotester

FTL670

Cover

Electronic insert

FEL67

Liquiphant S

(FailSafe)

s*

1. 2.

approx. 5 mm

Loading...

Loading...