Do you have a question about the Endress+Hauser Prosonic FMU 862 and is the answer not in the manual?

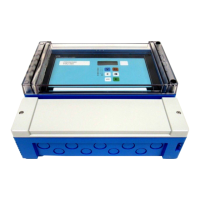

| Measurement Principle | Ultrasonic |

|---|---|

| Communication | HART, PROFIBUS PA, FOUNDATION Fieldbus |

| Process Temperature | -40 to +80 °C |

| Output Signal | 4 to 20 mA, HART |

| Power Supply | 24 V DC |

| Housing Material | Aluminum |

| Protection | IP66 |

| Display | LCD |

Options for field or control room, single or two-channel versions with relays and optional serial interface.

Easy setup with parameter matrix, linearisation functions, and fuzzy logic for stable measurement.

Water level measurement, e.g., for pump control in up to 5 stages, alternating pump control.

Flow rate measurement in flumes/weirs with millimeter accuracy, preset linearisation curves.

Differential level measurement, controlling screen cleaning, back water alarm.

Describes the ultrasonic pulse reflection and echo signal reception for height calculation.

Configuration via keypad and display using a standard matrix for easy parameter entry.

Minimised start-up time using preset parameters, automatically setting the measuring line.

Covers level measurement with characteristic curves and differential measurement, and flow rate measurement.

Remote configuration and data entry using Commulog VU 260 Z or HART communicator.

Details on connecting handheld terminals, required resistance, and technical data for communication.

Connecting intrinsically safe transmitters to a PC for remote operation using Commuwin II software.

Linking FMU 86... to existing process control systems via RS-485, PROFIBUS, FIP, or MODBUS.

Sensor installation in hazardous areas, transmitter in safe areas, observe local regulations.

Options for level and flow measurement, including single-channel and two-channel versions.

Loading...

Loading...