10

5.4 Hydraulic Oil

The hydraulic oil shown in the following table is approved for use

with the pump.

Temperature Range Approved Hydraulic Oil

°C °F

15 to 60 60 to 150 ADV Hydo 10 (SAE 10W)

Failure to use the specified oil may result in damage to

pump and other hydraulic components and will void the product

warranty.

Be sure that the oil is clean and that it is poured from a clean

container. The oil cleanliness should be maintained to a minimum

cleanliness level of 18/16/13 per the ISO4406 standard. If the oil

has a milky, cloudy or dark appearance, it should be changed

immediately as described in the pump maintenance instructions.

Use only a high quality hydraulic oil that meets the specifications

shown in the approved hydraulic oil table. Add oil only when all

system components are fully retracted, or the system will contain

more oil than the reservoir can hold.

For detailed instructions explaining how to add oil to the pump

reservoir, refer to the Smart Tensioning Pump instruction sheet

(document L4186).

5.5 Hydraulic Couplers

Each tensioner includes a male quick-disconnect style hydraulic

coupler. The Smart Tensioning Pump, and the connecting hoses

include similar male and female couplers.

Failure to observe the following precautions may result in

death or serious personal injury.

• On the Smart Tensioning Pump, pressure is automatically

relieved and directed to the pump reservoir when the motor

is stopped. However, as a precaution after stopping the motor

and before disconnecting electrical power, always verify that

zero (0) psi/bar is indicated on both the pump pressure gauge

and on the pump touchscreen HMI pressure readout.

• Be sure that pump motor is OFF before connecting or

disconnecting any couplers.

• Do not pressurize disconnected couplers. All couplers must

be correctly and completely fastened together before applying

pressure.

• Never disconnect any couplers without first unloading the

tensioners and releasing hydraulic pressure.

• Never attempt to relieve pressure by loosening a fitting or by

unseating a coupler check ball or seat.

All system pressure must be released prior to making

connections. If there is any pressure trapped in the hydraulic

components, it will be not possible to connect or disconnect

hoses using the couplers.

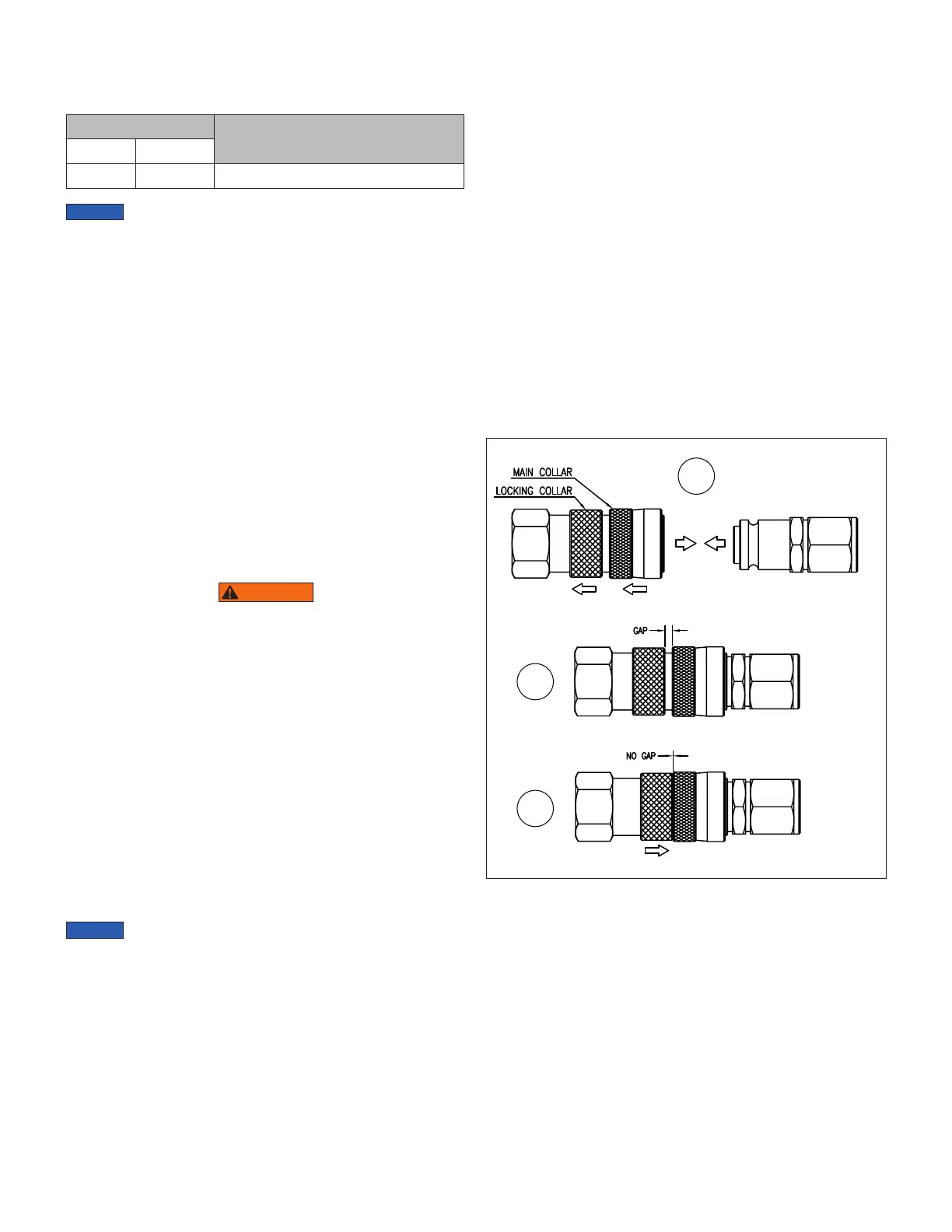

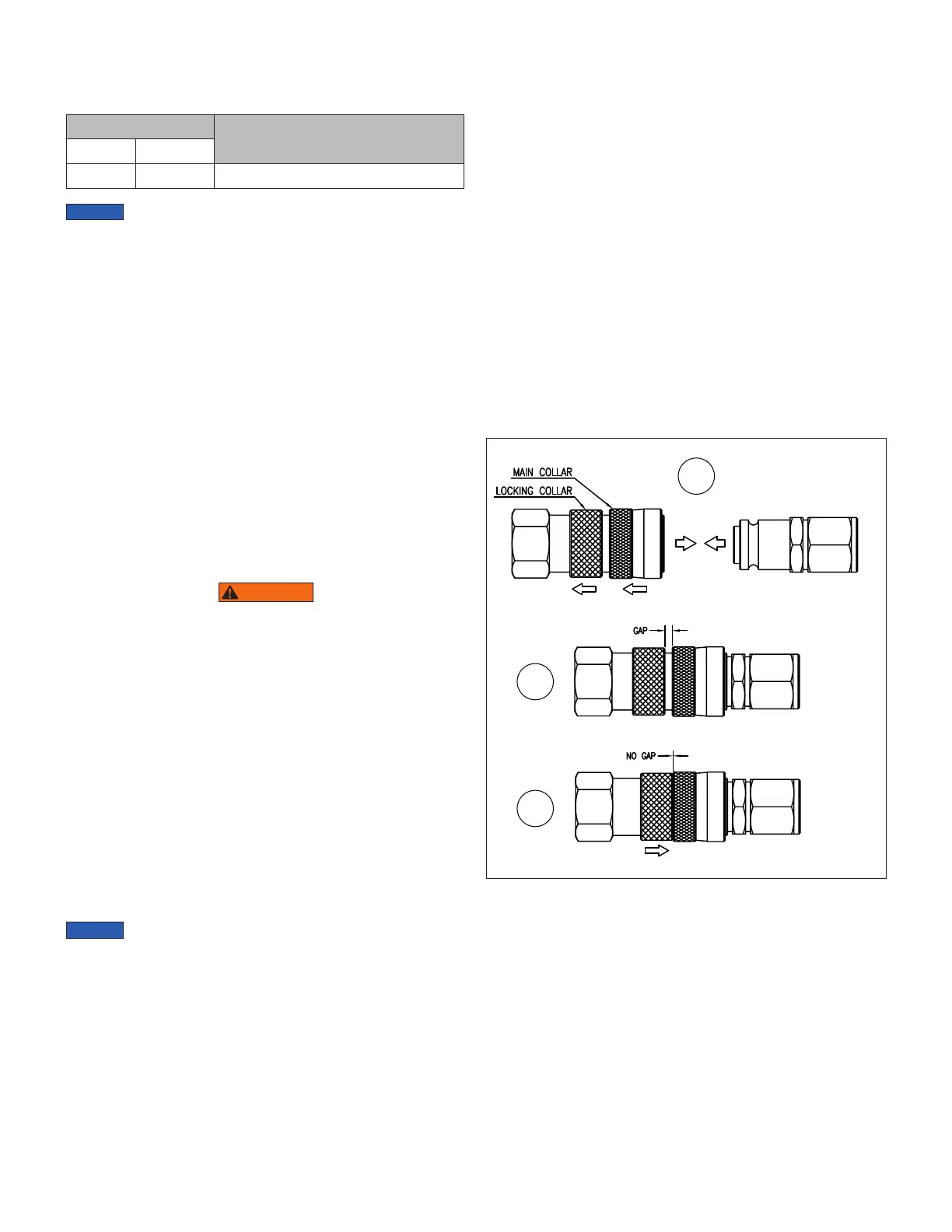

To Connect Couplers:

See Figure 8.

1. Before making any connections, be sure that the pump

pressure gauge and the touchscreen HMI pressure readout

both indicate (0) psi/bar.

2. Be sure that couplers are free of dirt and debris.

3. On the female coupler, be sure that the locking collar is

completely backed-o (unscrewed). Then, hold back the

main collar and push the male coupler into the female

coupler.

4. Release the main collar on the female coupler and push the

male coupler further into the female coupler until a “click” is

heard and engagement is felt.

5. Thread down the locking collar so it makes contact with the

main collar and locks the couplers together. There should be

NO GAP where the collars meet. Tighten by hand only. Do

not use tools.

6. At each coupler connection, firmly tug the hose to verify that

the couplers are securely connected. Verify the couplers

are locked by attempting to pull back the main collar on the

female coupler.

1

Hand Tighten

Pull BackLoosen

Connect

2

3

Figure 8, Hydraulic Couplers - Connect and Lock

To Disconnect Couplers:

See Figure 9.

1. Before disconnecting any couplers, be sure that the pump

pressure gauge and the touchscreen HMI pressure readout

both indicate (0) psi/bar.

2. On the female coupler, fully back-o (unscrew) the locking

collar to unlock the connection.

3. Pull back the main collar on the female coupler to disconnect

the couplers.

Loading...

Loading...