9

5.3 Tensioner Operational Checks

The following checks and inspections should be performed

before placing the tensioner into service, with the hydraulic hose

and electrical cables disconnected.

• Visually inspect the tensioner for any signs of damage or

excessive amounts of oil (which could indicate a potential

leak).

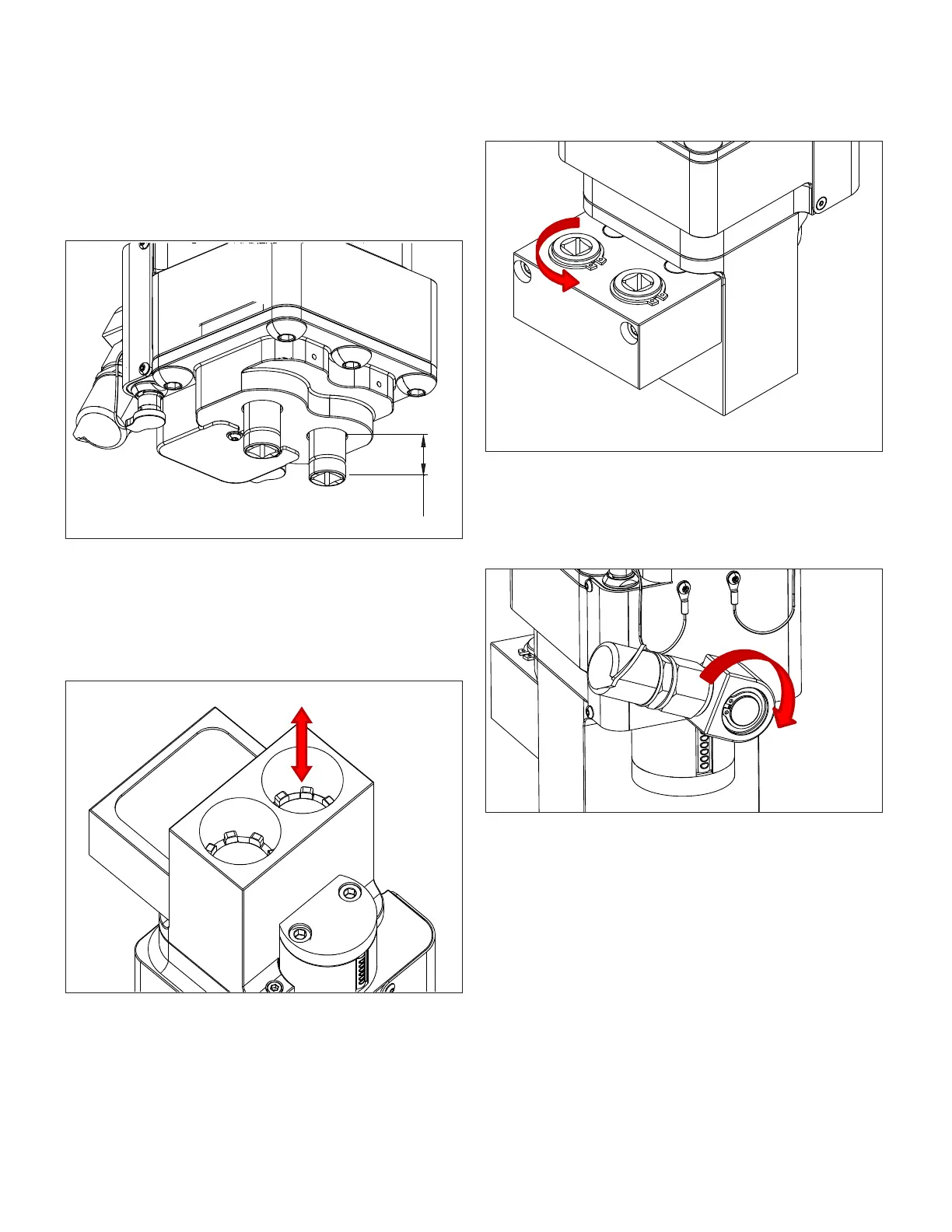

• Operational Check #1: Hold the tensioner upside down and

ensure that the puller sleeves freely retract by approximately

20 mm [0.78 in]. See Figure 4.

20 mm

[0.78 in.]

Figure 4, Checking Puller Sleeve Retraction

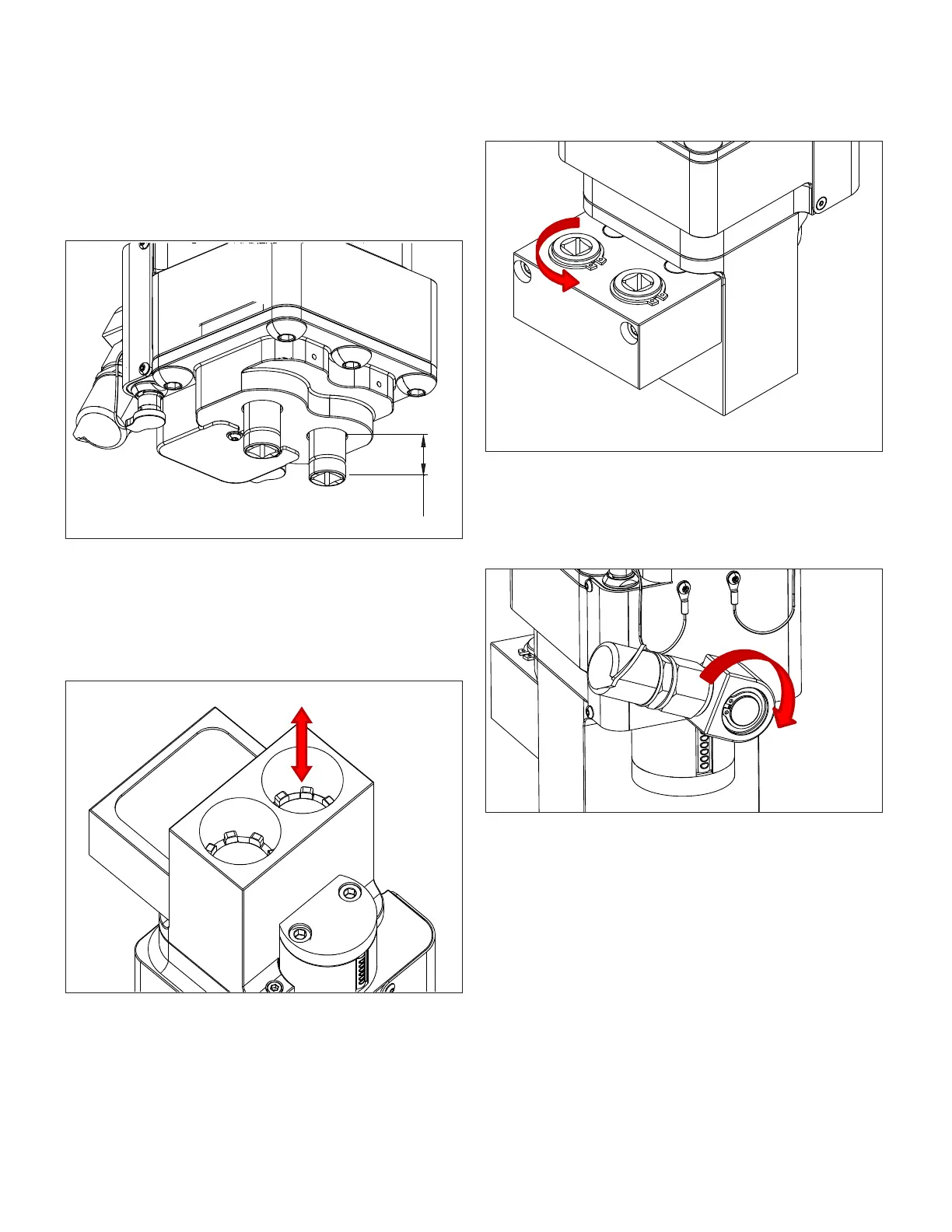

• Operational Check #2: With the tensioner still in the upside

down position, depress the nut rotating sockets by hand

by approximately 5-10 mm [0.20 - 0.39 in.] to ensure they

move freely and are returned to their original position by the

compression springs. See Figure 5.

Figure 5, Checking Spring Return

• Operational Check #3: Use a 3/8 inch drive extension to

rotate the drive gears on the gearbox at least one complete

revolution in both directions. Check that they rotate freely

without binding, and that they rotate the nut rotating sockets.

See Figure 6.

Figure 6, Checking Drive Gear Rotation

• Operational Check #4: Rotate the swivel manifold by hand at

least one complete revolution in both directions. Check that it

rotates freely without binding. See Figure 7.

Figure 7, Checking Puller Sleeve Retraction

If the tensioner is unable to successfully perform one or more of

the operational checks, it should be inspected and repaired by

an Enerpac Authorized Service Center before being placed into

service.

Loading...

Loading...