14

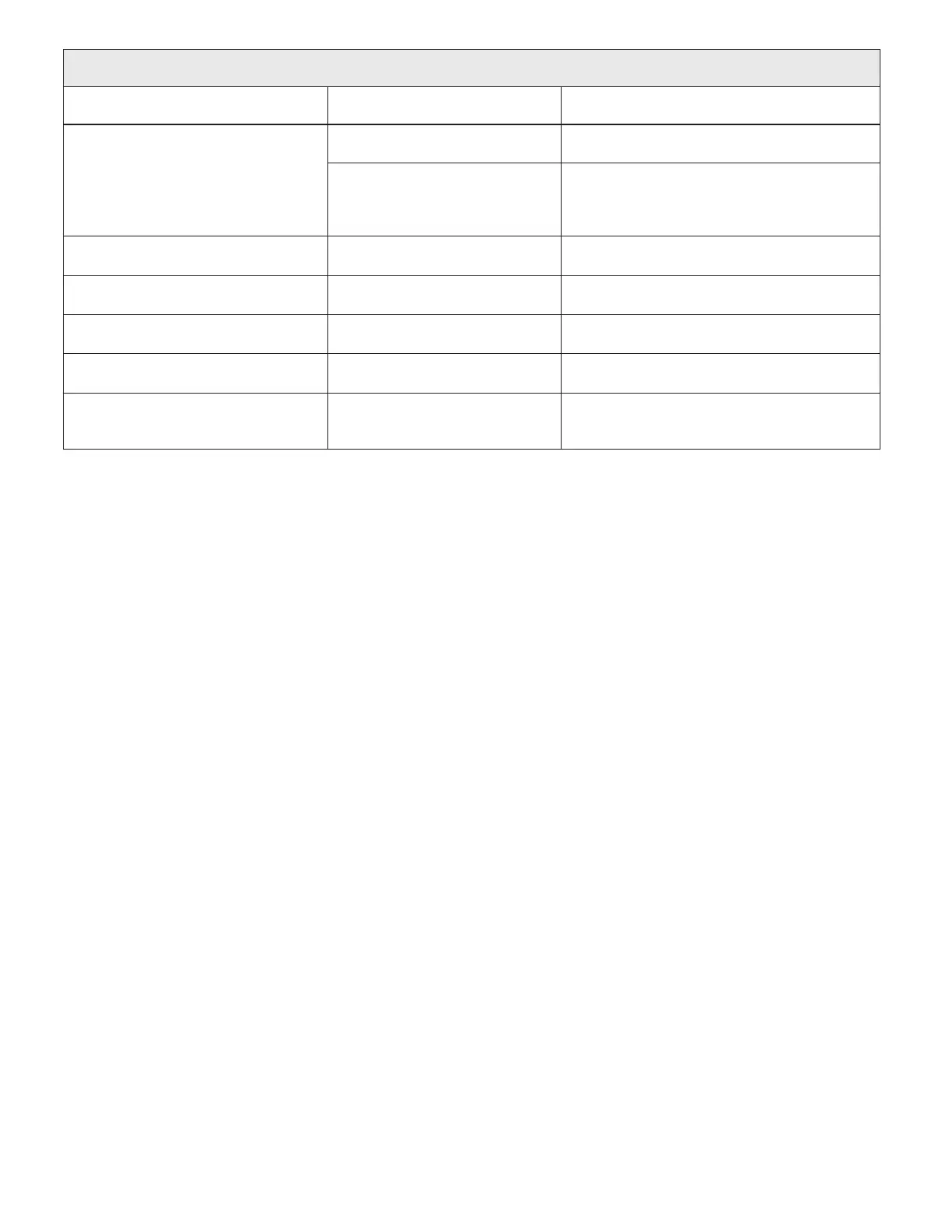

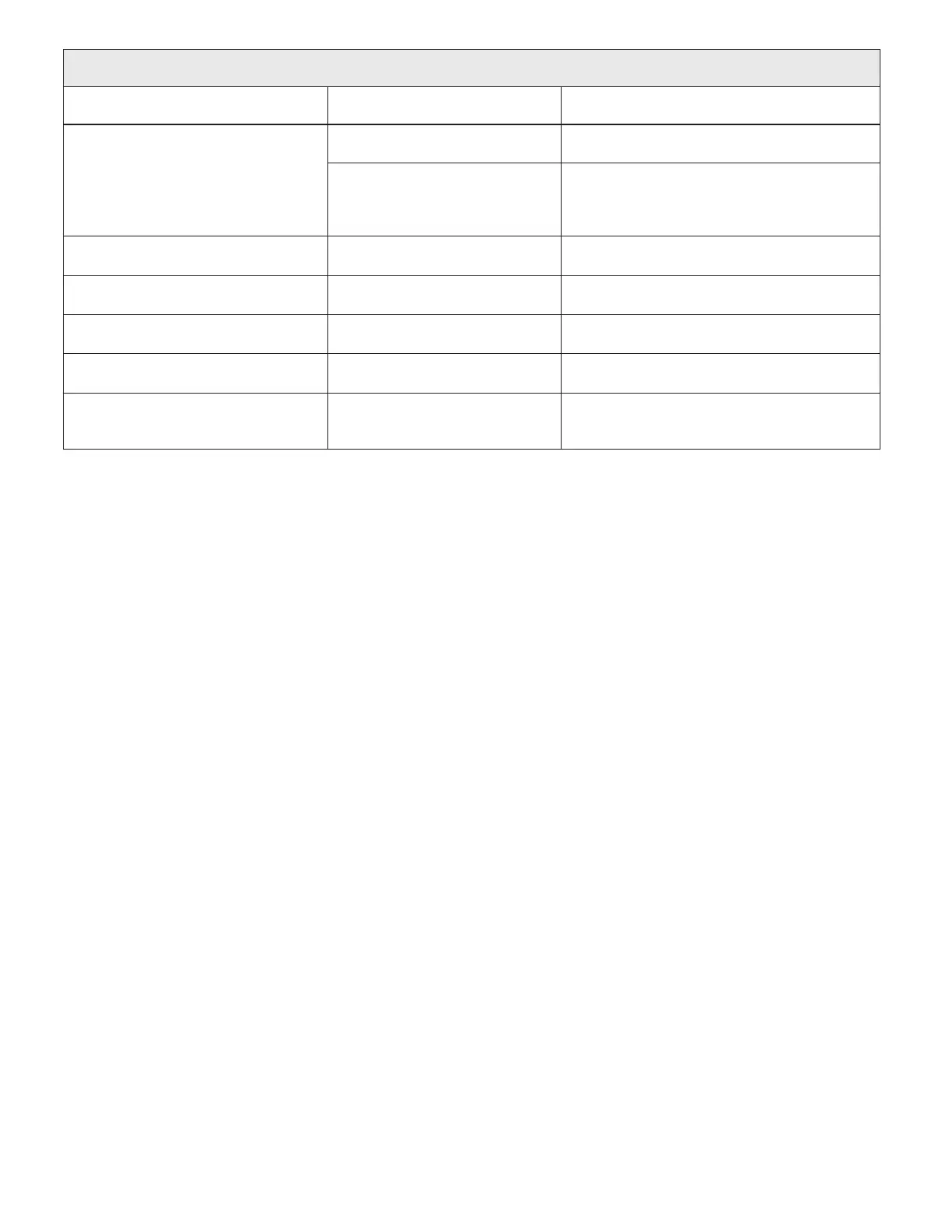

Troubleshooting Chart

Symptom Possible Cause Remedial Action

Puller sleeves not moving when they

should be moving.

Bad hydraulic connections. Check ALL hydraulic couplers for debris and

proper engagement.

Pump not building pressure. Check if pressure is increasing, using:

1) mechanical pressure gauge, 2) touchscreen

HMI readout, 3) amber LED on proportional relief

valve driver.

Oil leaking from tensioner. Over stroke protection activated. Press “motor o” button on hydraulic pump

pendant. Reinstall tensioner.

Nut rotating socket will not spin. Over torqued gearbox bolts. Loosen gearbox bolts until nut rotating socket

spins.

Transducers not providing feedback. Loose cable connection. Check ALL electrical cable connections for

debris, bent pins, and proper engagement.

Puller sleeves not returning to flush with

the top cap.

Bad hydraulic connections. Check ALL hydraulic couplers for debris and

proper engagement.

Puller sleeve not returning to flush with

the top cap.

Weak return spring force. With hose assembly connected, use ratchet to

manually bring puller sleeve to flush. Replace

broken or weak return springs.

Loading...

Loading...