5

1.3 Hydraulic Tensioner Safety Precautions -

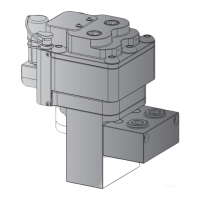

CAT 3600 Connecting Rod Tensioner

WARNING

Failure to observe the following precautions may result in

death or serious personal injury.

Hydraulic tensioners must be installed, operated and

maintained only by trained and skilled personnel familiar

with the safe operation of high pressure tensioning devices

and related equipment.

• Always wear eye protection, gloves and boots when working

near a pressurized hydraulic system.

• When working on site, the work area should be roped-o and

all non essential personnel not involved with the site operation

should be kept clear of the working area.

• Before starting tensioning procedures, be sure that all

personnel are aware that pressurization of high pressure

hydraulic equipment is about to occur.

• Never exceed the maximum working pressure of the hydraulic

tensioner (21,750 psi or 1500 bar).

• Do not exceed the maximum allowable stroke of the tensioner

pistons. An indicator (located on each tensioner sleeve) will

appear when the sleeve piston has reached its maximum

stroke. STOP pressurizing the tensioners immediately if this

indicator becomes visible.

• Never stand in-line with the bolt axis while tensioning or de-

tensioning is in progress. If the bolt or stud should fail, serious

personal injury or death could result if loose or broken parts

become projectiles. All personnel must be aware of this

potential hazard at all times.

• Allow personnel to be near pressurized hydraulic tensioners

only when absolutely necessary and only when the pressure is

steady. Continually observe the pump pressure gauge and the

touchscreen HMI pressure readout.

• Keep hands, fingers and other body parts clear of the

tensioner during tensioner operation. Do not attempt to move

or reposition the tensioner while it is pressurized.

• High pressure hydraulic equipment can be very dangerous if

misused. Keep away from oil leakages at high pressure. Liquid

escaping from highly pressurized equipment has sucient

power to penetrate the skin, which can cause blood poisoning.

In the case of such an accident, seek IMMEDIATE medical

attention.

• Never attempt to repair leaks while the system is pressurized.

Be sure system pressure gauge and the touchscreen HMI

pressure readout both indicate zero (0) psi/bar before

tightening fittings or beginning any repairs.

• Never attempt to disconnect a hydraulic coupler while it is

under pressure.

• Do not move or lift the hydraulic tensioners using the hydraulic

hoses and fittings.

• Hoses should not be twisted or bent too sharply. The bend

radius should not be less than the manufacturer’s specified

minimum bend radius for your hose type.

• Before pressurizing the system, carefully inspect all hydraulic

hose assemblies. Replace any damaged, crushed or kinked

hoses immediately.

• Before pressurizing the system, be sure that all hydraulic

hoses are connected. Each male coupler must be connected

to a corresponding female coupler. Verify that each coupler is

fully engaged and securely locked into position by physically

pulling on the connection.

• Never pressurize the back of a disconnected male coupler.

Male couplers cannot withstand high pressures when

disconnected. Serious personal injury could result if the

coupler fails while it is disconnected and under pressure.

• Use caution when pressurizing a system. Pressure can rise

faster than anticipated. Continuously monitor the pressure

gauge and the touchscreen HMI pressure readout during

pressurization. Be prepared to stop the pump immediately at

any time.

• Never leave a pressurized system unattended. If you must

leave the area, stop the pump and ensure that the hydraulic

pressure gauge and the touchscreen HMI pressure readout

both indicate zero (0) psi/bar.

• Use only the Smart Tensioning Pump (model No. 498-6540

or 498-6541) to power the tensioners. The tensioners are

designed for use only with this pump.

• Any maintenance or repairs to the tensioners, the pump or

related components must be performed with the equipment in

the unpressurized state (0 psi/bar).

Loading...

Loading...