7

1 2 3 4

5

6

7

8

9

10

11

12

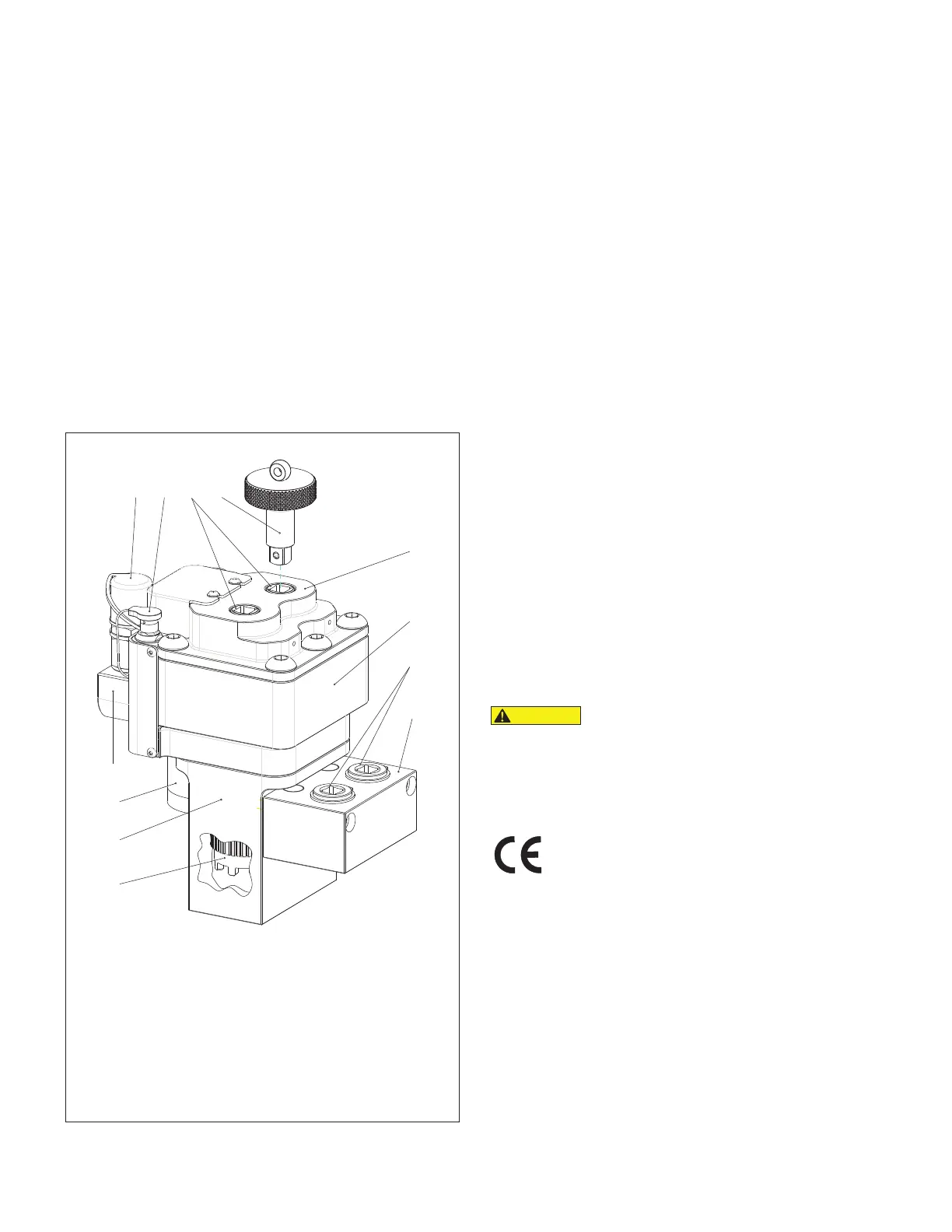

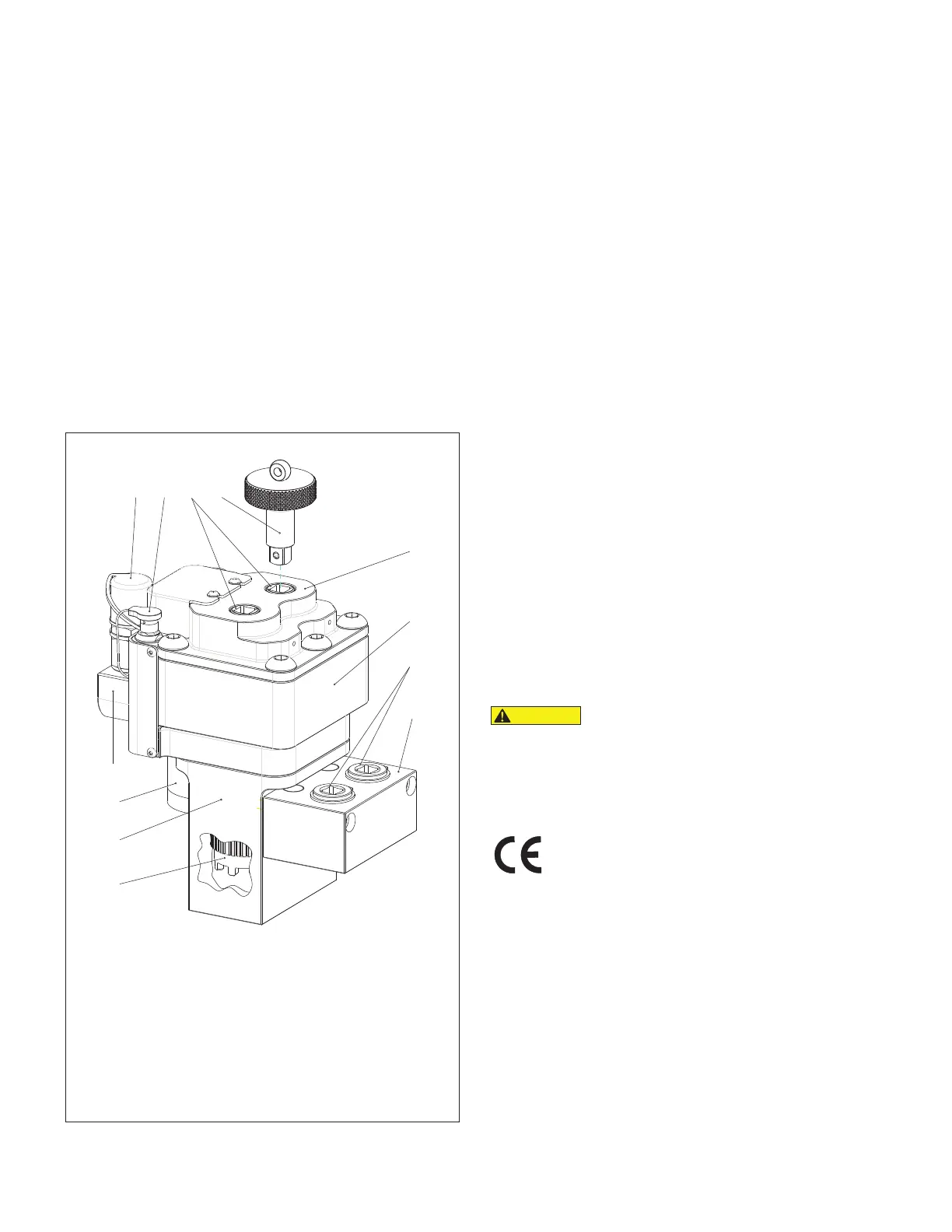

Figure 1, Major Features and Components

Key:

1. Coupler, Male

2. Electrical Connector

3. Puller Sleeves *

4. Thumb Wheel, 3/8 in.**

5. Top Cap

6. Tensioner Body

3.0 PRODUCT DESCRIPTION

3.1 Overview

The Enerpac Model 498-6547 hydraulic tensioner is designed to

precisely tension the connecting rod studs used on CAT 3600

Series engines. It includes the following features:

• Application specific design - custom engineered to precisely

fit CAT 3600 connecting rods.

• Overstroke protection.

• Twin stud tensioning

• Fast castle nut spin down using standard 3/8" square drive.

The tensioner is part of a complete tensioning system that

includes a specially programmed Smart Tensioning Pump. This

pump oers the following advanced features:

• Convenient touchscreen HMI (human-machine interface).

• Automated GO/NO-GO operation with transducer feedback.

• Quality record (Includes: system pressure, tensioner piston

travel, operator ID, serial number and time stamp).

7. Drive Gears *

8. Gearbox

9. Nut Rotating Sockets

10. Tensioner Bridge

11. Cycle Counter

12. Swivel Manifold

* 3/8 inch drive. ** Item included in tensioning kit.

3.2 Additional Tensioner Features

• The tensioner mounts and operates quickly, since it is

especially designed for the CAT 3600 tensioning application.

• The puller sleeves and drive gears contain standard 3/8

inch female square drives. This allows the technician to easily

complete various operations that are part of the tensioning

process.

• Built-in electrical transducers help ensure that proper

tensioning procedures are followed.

• Cycle counter indicates tool cycles, and can be used to

determine when routine inspection and maintenance activities

are required.

• Durable black oxide finish helps protect the tensioner from rust

and corrosion, prolonging its life.

See Figure 1 for a diagram of the tensioner's major features and

components.

3.3 Maximum Working Pressure -

CAT 3600 Tensioning Application

The maximum working pressure for the CAT 3600 tensioning

application is regulated by the Smart Tensioning Pump, when the

pump is operated in the automatic program (P) mode. Note that

this pressure can be less than the maximum working pressure

(“WP”) stamped on the side of the hydraulic tensioners. This

pressure can also be less than the maximum pressure shown on

the pump data plate.

Program (P) mode limits the pump's maximum working

pressure to a setting determined by the Caterpillar Engine

Products Group. The pressure is automatically optimized for the

selected application, to help prevent bolt failure due to over-

pressurization.

The pump also contains a manual (M) mode. The manual mode

should be used only for troubleshooting or diagnostic purposes

while the tensioner is not mounted on the connecting rod, and

with use of appropriate fixturing to prevent over-stroke of the

tensioners.

CAUTION

Use of the pump in manual mode with the

model 498-6547 Smart Tensioners may result in incorrect

clamp load and/or failure of the connecting rod studs.

Tensioner could drop if studs break, possibly injuring

persons in the work area. Property damage could also result.

3.4 Conformance to National & International Standards

Enerpac declares that the Enerpac Smart Tensioner

has been tested and conforms to applicable standards

and is approved to carry the CE certification mark. An

EU Declaration of Conformity is enclosed separately.

4.0 IMPORTANT RECEIVING INSTRUCTIONS

Visually inspect all components for shipping damage. Shipping

damage is not covered by warranty. If shipping damage is found,

notify carrier at once. The carrier is responsible for all repair and

replacement costs resulting from damage in shipment.

Loading...

Loading...