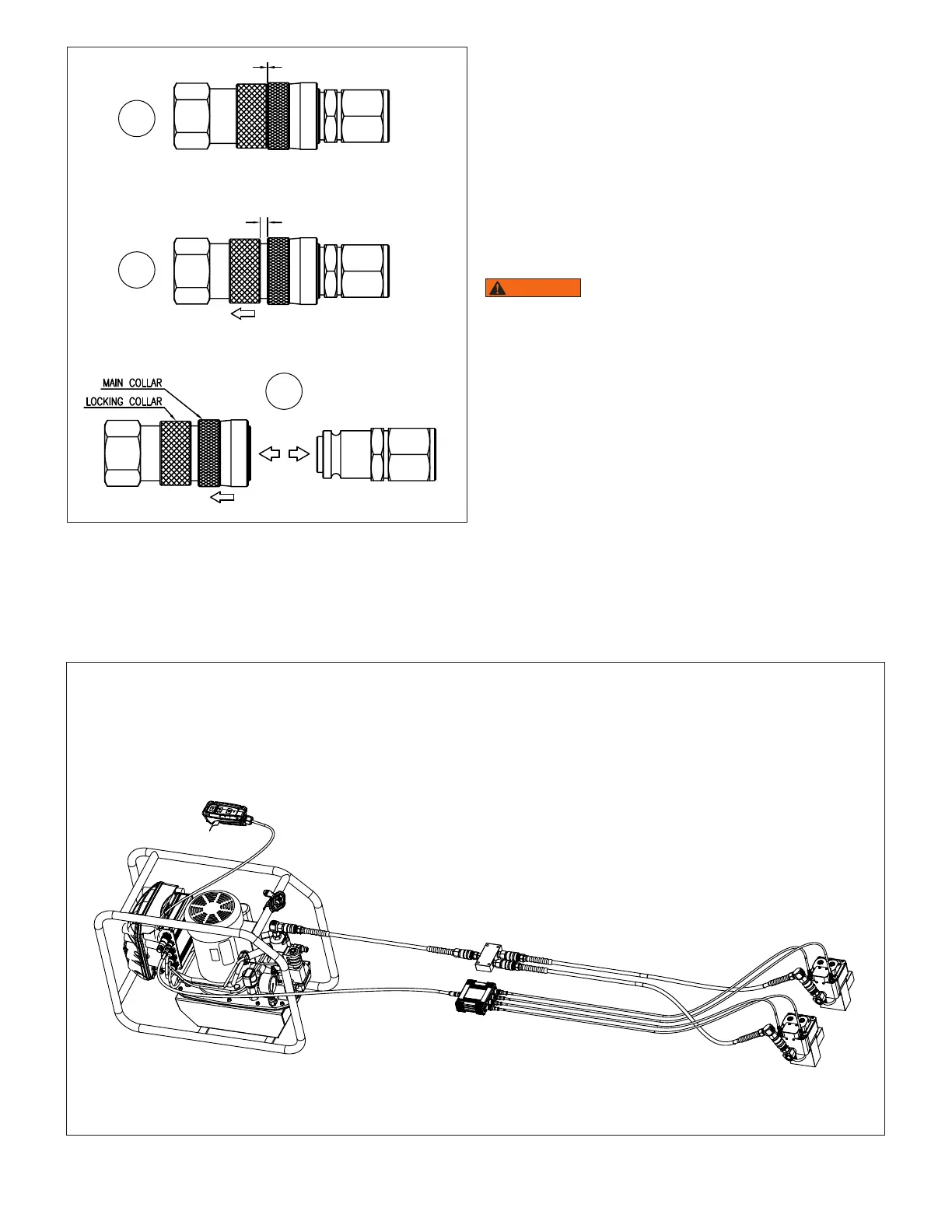

11

GAP

NO GAP

Loosen

Pull Back

Disconnect

1

2

3

Figure 9, Hydraulic Couplers - Unlock and Disconnect

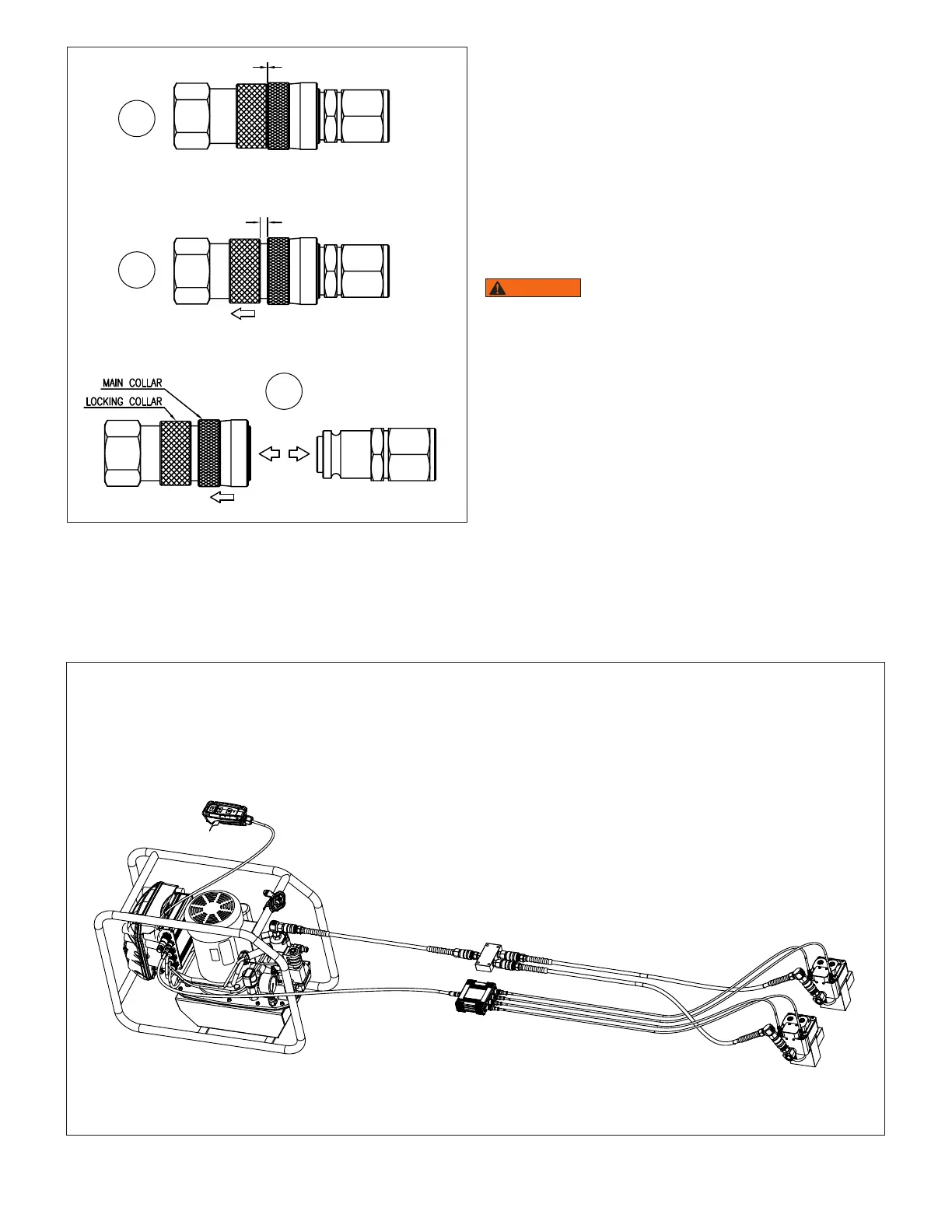

5.6 Hose and Cable Assemblies

See Figure 10 for an overall view of the hoses, cables, flow-

divider and junction box.

For detailed hose and cable connection instructions, refer to the

Smart Tensioning Pump instruction sheet (document L4186).

Before connecting or disconnecting hydraulic couplers on hoses,

tensioner, pump and other hydraulic devices:

• Be absolutely certain that any pressure is completely relieved.

Verify that both the pump hydraulic pressure gauge and the

touchscreen HMI pressure readout indicate zero (0) bar/psi.

• Be certain that the pump motor is o and that the pump control

valve is not energized

WARNING

All hoses, fittings and components used in the

system, MUST be rated at or above the maximum rated working

pressure of the tensioner - 21,750 psi [1500 bar]. Failure to

observe this instruction could result in dangerous high pressure

oil leakage. Death or serious personal injury could result if a high

pressure oil stream penetrates the skin.

5.7 Preparation for Tensioning Procedures

• Be sure all personnel involved in this procedure are trained

in tensioning procedures and in the equipment being used.

Ensure that all personnel read and understand the safety

information contained in Section 2 of this document.

• Read and completely follow the additional pump setup

instructions contained in pump instruction sheet L4186. Be

sure that the pump reservoir is filled with oil.

• Be sure all personnel are familiar with the use of the Smart

Pump and its HMI screens. Refer to the Smart Tensioning

Pump instruction sheet (document number L4186) for

additional information.

• Inspect the connecting rod studs to verify that they contain no

Figure 10, Hose and Cable Assembly

Notes:

• Refer to smart tensioner pump manual

(document No. L4186) for detailed hose and

cable connection diagrams.

• For illustrative purposes, touchscreen HMI and

chafe gear protective coverings are not shown

in this graphic.

Loading...

Loading...