12

obvious damage or defects, and that they appear capable of

withstanding the force that will be applied by the tensioners.

• Ensure that the connecting rod caps are correctly and firmly

seated, and that the nuts are fully threaded onto the studs

until they firmly contact the connecting rod cap surface.

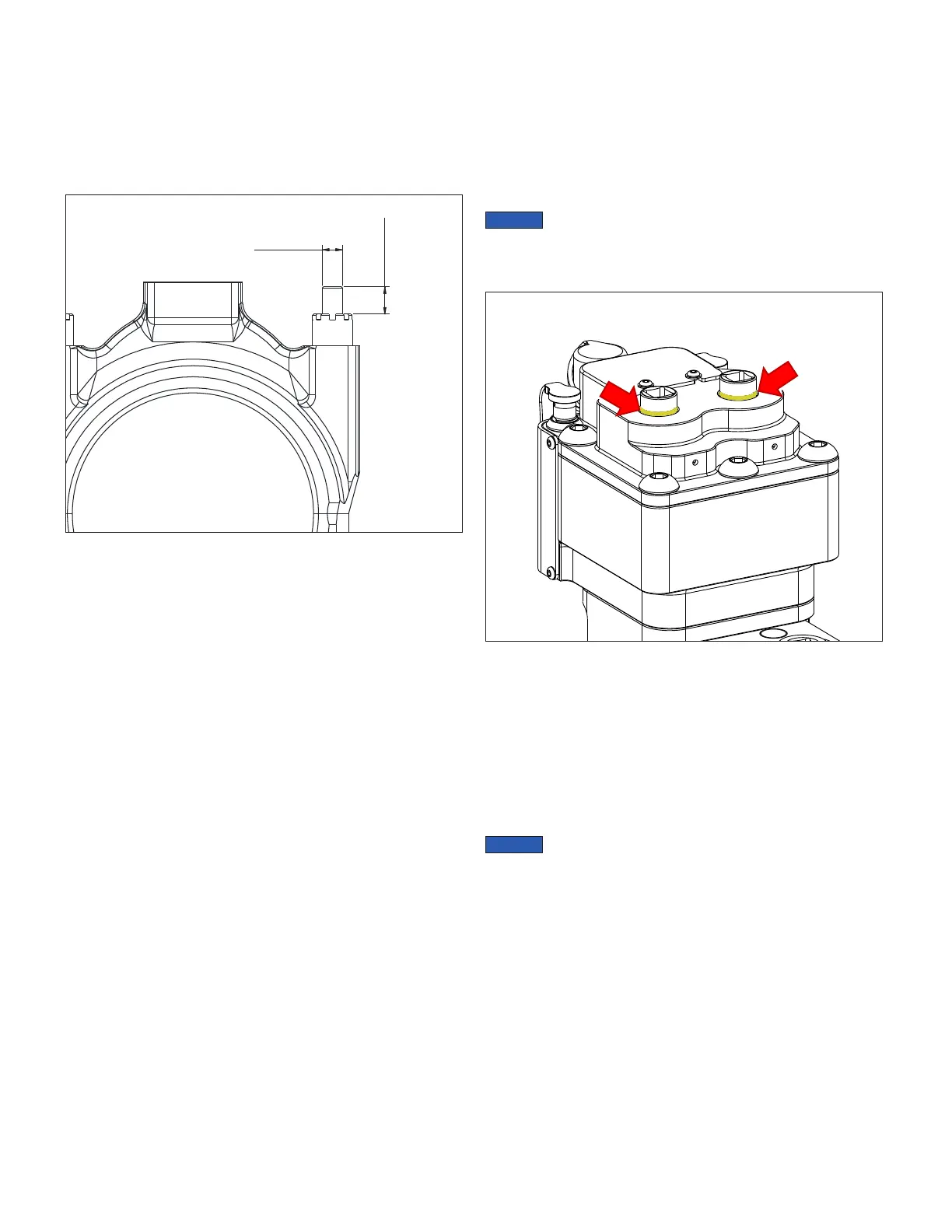

There should be a total of 26 mm [1.02 inch] above each nut.

Absolute minimum stud protrusion required to safely tension

the studs is 21 mm [0.83 inch]. See Figure 11.

26 mm

[1.02 in.]

M19 x 1.5

Figure 11, Checking Stud Protrusion

• Before installing each tensioner, be sure that the threaded

portions of the studs and puller sleeves are clean and free of

damage.

• Before using the tensioner and pump, use the pump's oil flush

feature to remove any trapped air from the system. Refer to

the pump instruction sheet (document No. L4186) for oil flush

procedure.

6.0 TENSIONING PROCEDURES

• Refer to the Caterpillar 3600 connecting rod Disassembly and

Assembly instructions (available from Caterpillar) for detailed

tensioner installation and operation procedures.

• Refer to the Smart Tensioning Pump instruction sheet

(document No. L4186) for detailed pump set-up instructions

and user-level pump troubleshooting information.

• If oil leaks occur or if abnormal operation is noticed, STOP the

pump immediately and determine the source of the problem

before resuming the tensioning procedure.

7.0 ADDITIONAL PRODUCT FEATURES

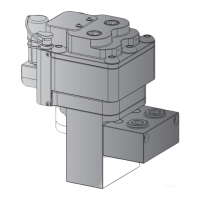

7.1 Maximum Stroke Indicator

Maximum allowable tensioner stroke is visually indicated

by a yellow painted groove located on the puller sleeve’s

circumference. See Figure 12.

Continually watch for the maximum stroke indicator during

tensioning procedures. Stop pressurizing the system immediately

if the indicator becomes visible at one or both puller sleeves.

The maximum stroke indicator groove can be felt by hand. If

the view of the tensioner is restricted or obstructed, periodically

check for the groove by hand as tensioning procedures are

performed.

Reaching maximum stroke is a possible indication of a problem

with the connecting rod assembly.

If the maximum stroke indicator appears before the desired

hydraulic pressure is reached, always stop the pump and verify

that pressure is fully relieved (0 psi/bar).

Check for obvious problems, such as broken connecting rod

studs or worn threads. Also check for correct assembly of parts.

Reassemble and/or replace parts as required. Then, repeat the

tensioning process.

If the maximum stroke indicator appears before the

desired hydraulic pressure is reached, no additional load will be

transferred to the connecting rod studs, and the studs and nuts

will not be tensioned to the correct values.

Figure 12, Maximum Stroke Indicators

7.2 Over-Stroke Protection System

The tensioner contains an over-stroke protection system. This

feature helps reduce the risk of damage to both the tensioner and

the connecting rod studs.

The over-stroke protection system is activated after the maximum

stroke indicator (on either one or both puller sleeves) is fully

exposed. Oil leakage will be visible in the top cap area when

pressure relief occurs.

Clean-up any leaked or spilled oil. Dispose of this oil in

accordance with all applicable regulations and laws.

Loading...

Loading...