11

WARNING

Continuously monitor the load and be

prepared to stop the pump immediately. Never allow the

pump to operate in the latched mode while it is unattended.

When in latched mode, pump will shut o automatically

after 5 minutes if it is not stopped sooner by the operator.

Monitor the hydraulic reservoir oil level when

operating the pump in latched mode for a prolonged period of

time. Be careful not to allow the reservoir to become completely

drained of oil.

Pendant Haptic Pulse Feature

• To provide positive confirmation of pump status, the pendant

will vibrate haptic pulses as the pendant buttons are depressed

and released.

• One haptic pulse indicates that the motor has started. Two

haptic pulses indicate that the motor has stopped.

• The pendant will vibrate haptic pulses In conjunction with the

flashing LED indicator to signal when a fault code has been

triggered. Refer to Section 14.0 for additional information.

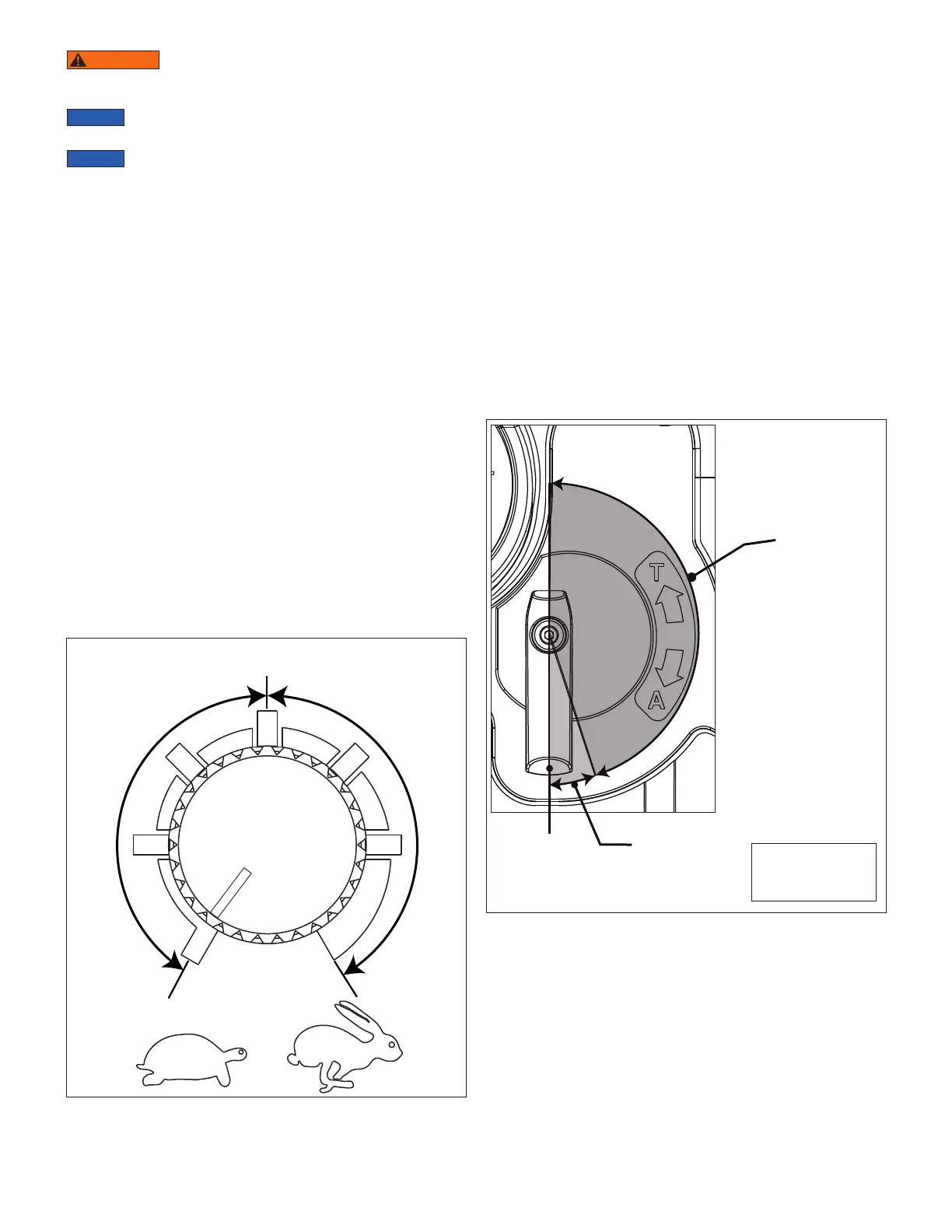

6.4 Variable Speed Control

A rotary knob mounted on the pump rear panel controls the

motor speed. See Figure 5.

The adjustable speed range is approximately 25 to 100% of full

rated output, or about 600 to 2400 RPM.

• Knob turned fully counterclockwise equals approximately

25% of rated output. This is the lowest possible setting.

• Midpoint setting of knob equals approximately 50% of rated

output.

• Knob turned fully clockwise equals 100% full rated output or

maximum possible speed as determined by the pump internal

controls, based on operating conditions.

C

o

n

s

t

a

n

t

S

p

e

e

d

M

o

d

e

C

o

n

s

t

a

n

t

P

o

w

e

r

M

o

d

e

Figure 5, Speed Control Knob

SLOW

FAST

(25%)

(50%)

6.5 Constant Speed and Constant Power Modes

• When the speed control knob is set between the full counter-

clockwise (25%) and midpoint (50%) positions, the pump

operates in constant speed mode. In this mode, the motor speed

will not automatically increase or decrease to compensate for

changes in load. The user can precisely regulate the amount

of hydraulic flow and can manually reduce the flow rate, as

needed, to provide increased control and slower movement.

• When the speed control knob is set between the mid point

(50%) and full clockwise (100%) positions, the pump operates

in constant power mode. In this mode, the pump motor will run

at the set speed until maximum power is delivered. If the load

further increases, the motor will automatically reduce speed to

maintain peak torque (and hydraulic force) under demanding

conditions.

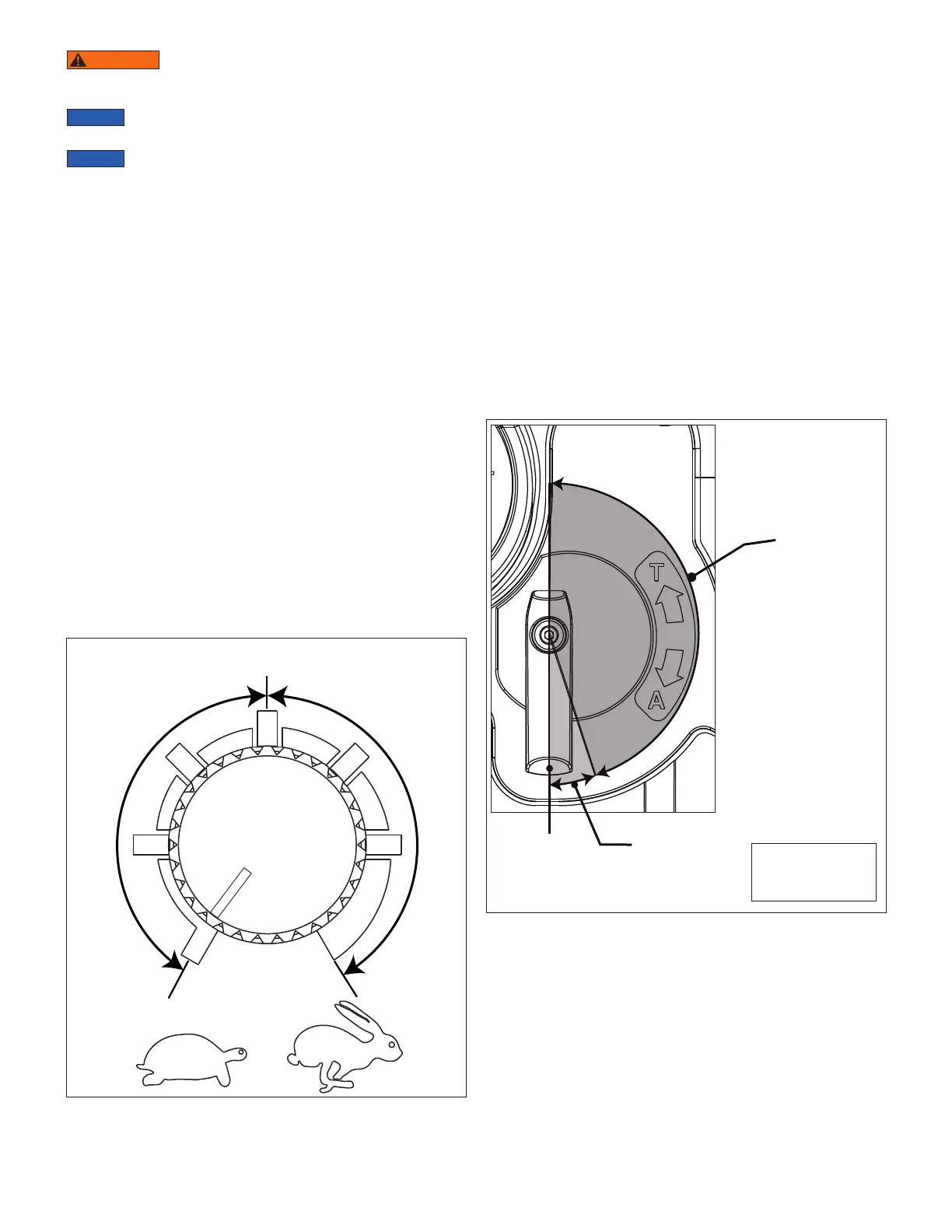

6.6 3-Way, 2-Position Control Valve (EP3204J Models)

The control valve on EP3204J models is operated by a rotary

lever and has two positions, “A” Advance and “T” Tank (return).

It is designed for use with single-acting hydraulic cylinders and

tools. See Figure 6.

Figure 6, Control Lever Positions - EP3204J Models

TANK

(RETURN)

FLOW

METERING

RANGE

T

A

Note: Lever

positions shown

are approximate.

• The pump must be running to advance the cylinder or tool.

• Moving the lever fully to the “A” position will direct hydraulic

flow from the pump reservoir to the cylinder or tool.

• Moving the lever from the “A” position to the “T” position

will direct hydraulic flow from the cylinder or tool back to the

reservoir. This is typically done with the pump turned-o.

• If the pump is turned-o while the lever is in the “A” position,

the cylinder or tool will stop and the pump internal valving will

hold the load in most applications. However, since the pump

contains no safety locking valve, suitable blocking must be

placed immediately under the raised load.

Loading...

Loading...