15

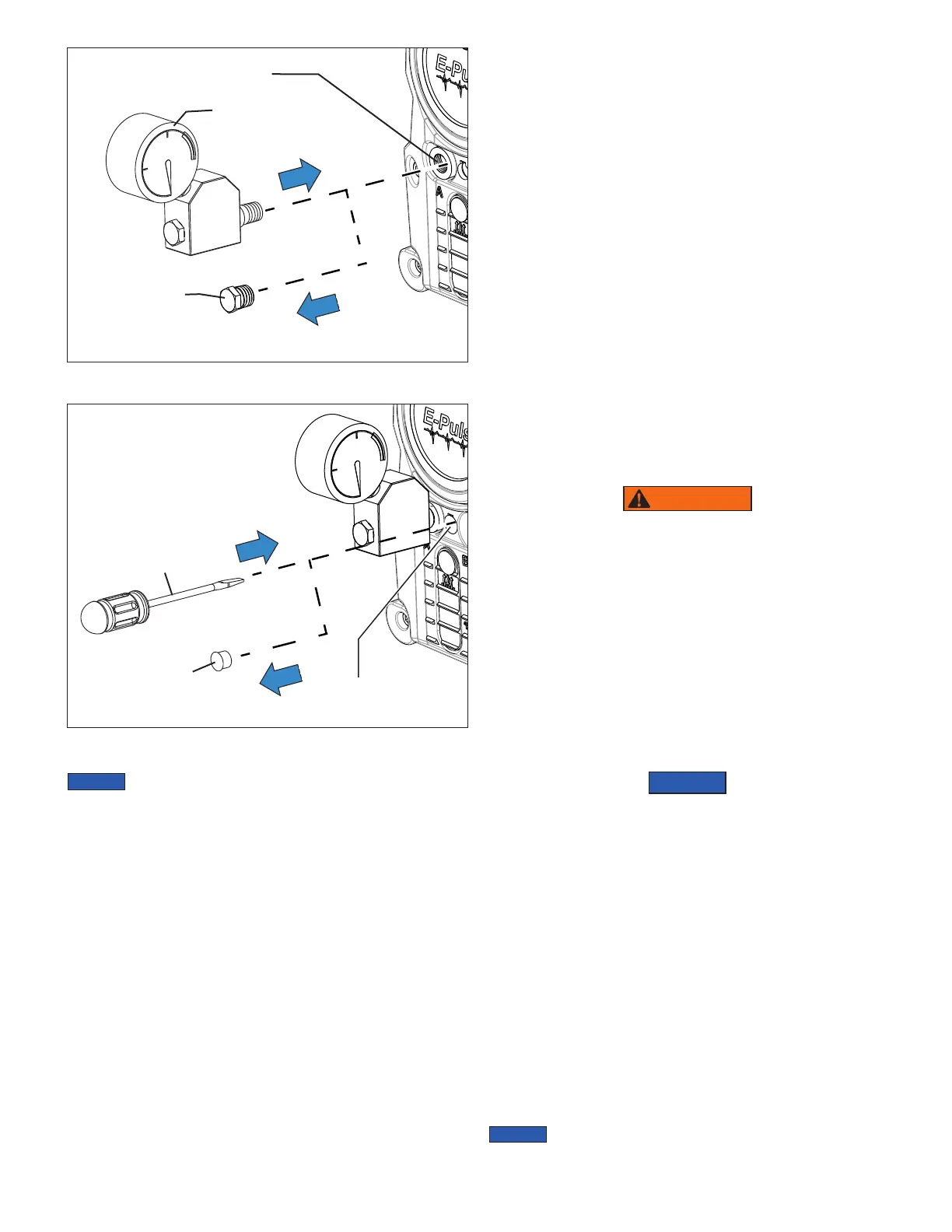

Figure 10, Pressure Gauge Installation

Pressure

Gauge

A Port

Plug

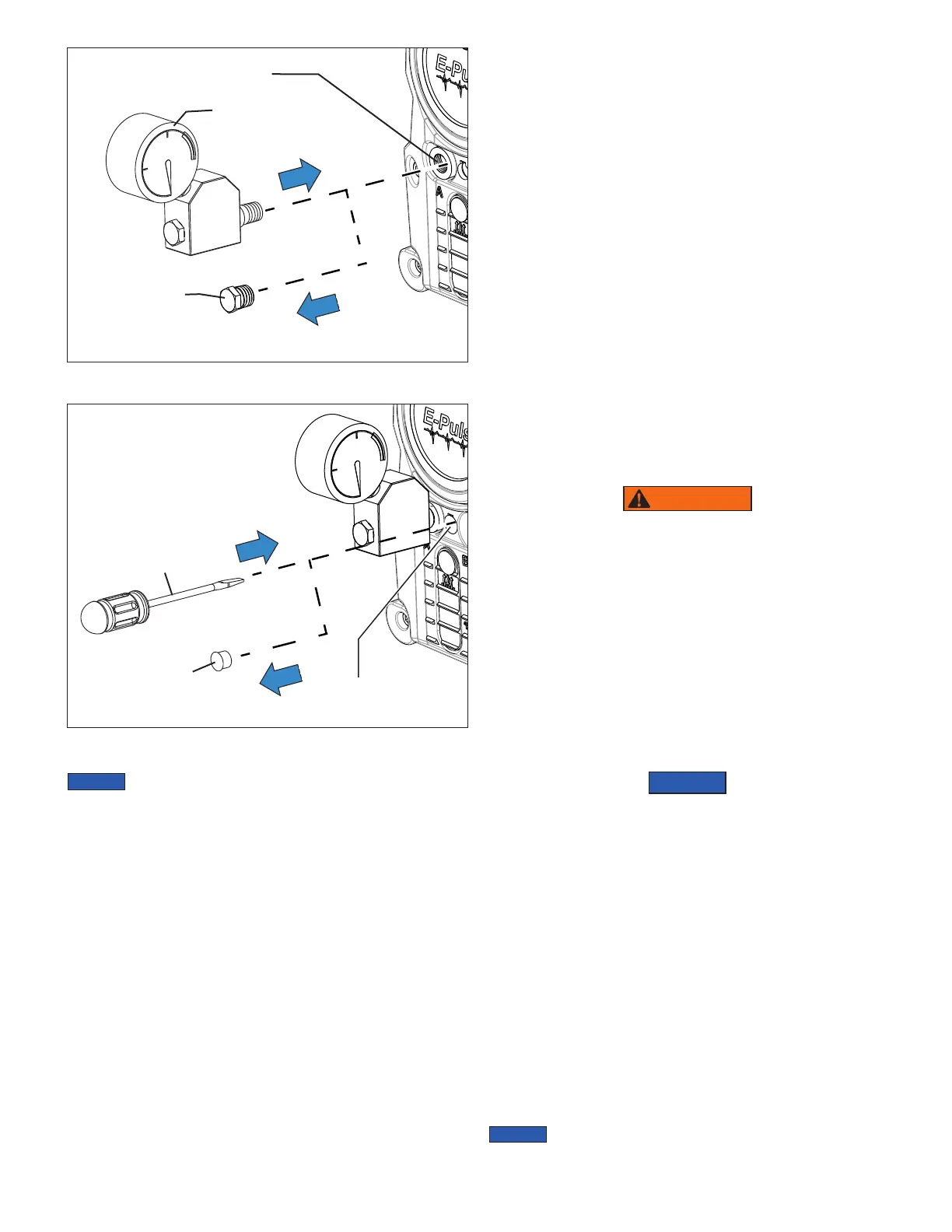

Figure 11, Pressure Relief Valve Adjustment

Screwdriver

Cover

Relief Valve

Access Hole

An internal check valve will prevent the pressure from

dropping if the set screw is turned counter-clockwise while the

control valve lever is in the “A” position. To lower the pressure,

follow steps 12a through 12e.

12. To decrease the relief valve setting:

a. Be sure the pump is running.

b EP3204J Models Only: Move the control valve lever to

the “T" position.

EP3404J Models Only: Move the control valve lever to

the “N” position.

c. Turn the relief valve screw counter-clockwise one turn. If

a very low pressure setting is desired, turn the relief valve

screw additional turns until it becomes loose.

d. Move the control valve lever to the “A” position.

e. With the pump running and while watching the pressure

gauge, SLOWLY turn the relief valve screw clockwise

until the “A” port pressure increases to the desired

setting.

13. When the desired pressure setting is reached, remove the

screwdriver.

14. Stop the pump.

15. EP3204J Models Only:

Move the control valve to the “T”

position. Check that pressure gauge indicates zero (0) psi/bar.

EP3404J Models Only: Move the control valve back and

forth between the “A”, “N” and “B” positions several times.

Check that pressure gauge indicates zero (0) psi/bar.

16. Move the control valve lever to the “A” position. Start the

pump and watch the pressure gauge. Verify that the desired

pressure is shown.

• If the pressure setting is correct, continue with steps 17-21.

• If the pressure setting is NOT correct, repeat steps 6 through 16.

17. EP3204J Models Only: Move the control valve to the “T”

position to relieve any trapped system pressure. Check that

pressure gauge indicates zero (0) psi/bar.

EP3404J Models Only: Move the control valve back and

forth between the “A”, “N” and “B” positions several times

to relieve any trapped system pressure. Check that pressure

gauge indicates zero (0) psi/bar.

18. Remove pressure gauge from the pump “A” port.

19. EP3404J Models Only: Remove the 3/8" NPTF pipe plug

from the pump “B” port.

20. Reinstall protective cover over the relief valve access hole.

21. Reconnect hydraulic hose(s) to pump.

10.0 HYDRAULIC SYSTEM MAINTENANCE

WARNING

Failure to observe and comply with the following precautions

could result in death or serious personal injury. Property

damage could also occur.

• To avoid accidental starting, be certain that the pump AC

power cord is disconnected from the electrical outlet before

performing any maintenance procedures.

• Be certain that all system hydraulic pressure is completely

relieved before performing any maintenance procedures.

Refer to information in Section 8.0.

10.1 Hydraulic Oil Information

Enerpac HF hydraulic oil (ISO Grade 32) is the recommended oil

for all E-Series pumps. This oil is suitable for most applications

and working environments.

• Use of oils other than Enerpac HF may result in damage

to pump hydraulic components and will void the Enerpac

product warranty. Enerpac recommends using only Enerpac

HF oil in the E-Series pumps.

• Never mix oils of dierent viscosities. Mixing oil viscosities

may result in damage to pump components and will void the

Enerpac product warranty.

10.2 Checking the Oil Level

1. Be sure that hydraulic cylinder or tool is fully retracted.

2. Be certain that pump is stopped and that all hydraulic

pressure is fully relieved before continuing this procedure.

Refer to Section 8.0.

3. Be sure that the pump is placed on a level surface.

4. Check the oil level indicator. Verify that the oil level is up to

the full mark. Refer to Figure 12.

If oil level is low: Add oil as described in Section 10.3. Refer

to Section 10.1 for oil specifications.

Be sure that the oil is clean. If the oil has a milky,

cloudy or dark appearance, it should be changed immediately

as described in Section 10.4.

Loading...

Loading...