9

4.0 PRODUCT DESCRIPTION

4.1 Introduction

The Enerpac E-Series electric manual valve pumps are designed

for use with industrial hydraulic cylinders and tools rated at

10,000 psi [700 bar] working pressure.

Features include:

• Manual 3-way, 2-position control valve (EP3204J Models) or

manual 4-way, 3-position control valve with tandem center

(EP3404J Models).

• Remote control 2-button Smart IQ pendant with LED status

and diagnostic indicator.

• Choice of jog (momentary on) or latched (constant on)

operational modes.

• Variable speed permanent magnet direct drive motor with

unique constant power mode.

• Durable and lightweight all aluminum chassis construction.

• Two-stage pump design for fast system fills and controlled

flow at high pressures.

• Six discreet pump elements provide even flow and smooth

operation.

• Built-in user and service center diagnostic features.

Refer to Figure 2 for a diagram of the pump's major features and

components.

4.2 Conformance to National & International Standards

Enerpac declares that the E-Series pumps have been

tested and conform to applicable standards and are

approved to carry the CE, TUV C and US, and FCC

certification marks. An EU declaration of conformity is included

in the shipment.

4.3 Electromagnetic Compatibility (EMC)

Enerpac E-Series pumps have been tested and certified to

conform to CE-EMC Emission and Immunity standards and to

FCC emission standards.

5.0 PREPARATION FOR USE

5.1 Important Receiving Instructions

Visually inspect all components for shipping damage. Shipping

damage is not covered by warranty. If shipping damage is found,

notify carrier at once. The carrier is responsible for all repair and

replacement costs resulting from damage in shipment.

Note that a small amount of residual hydraulic oil may be present

within the packaging from product final assembly and testing

procedures. In addition, a small amount of hydraulic oil may

leak from the reservoir air breather (covered by a removable

absorbent pad) during shipping. A minimal amount of oil inside

the shipment should be considered as normal and not as a

cause for concern.

5.2 Hydraulic Connections

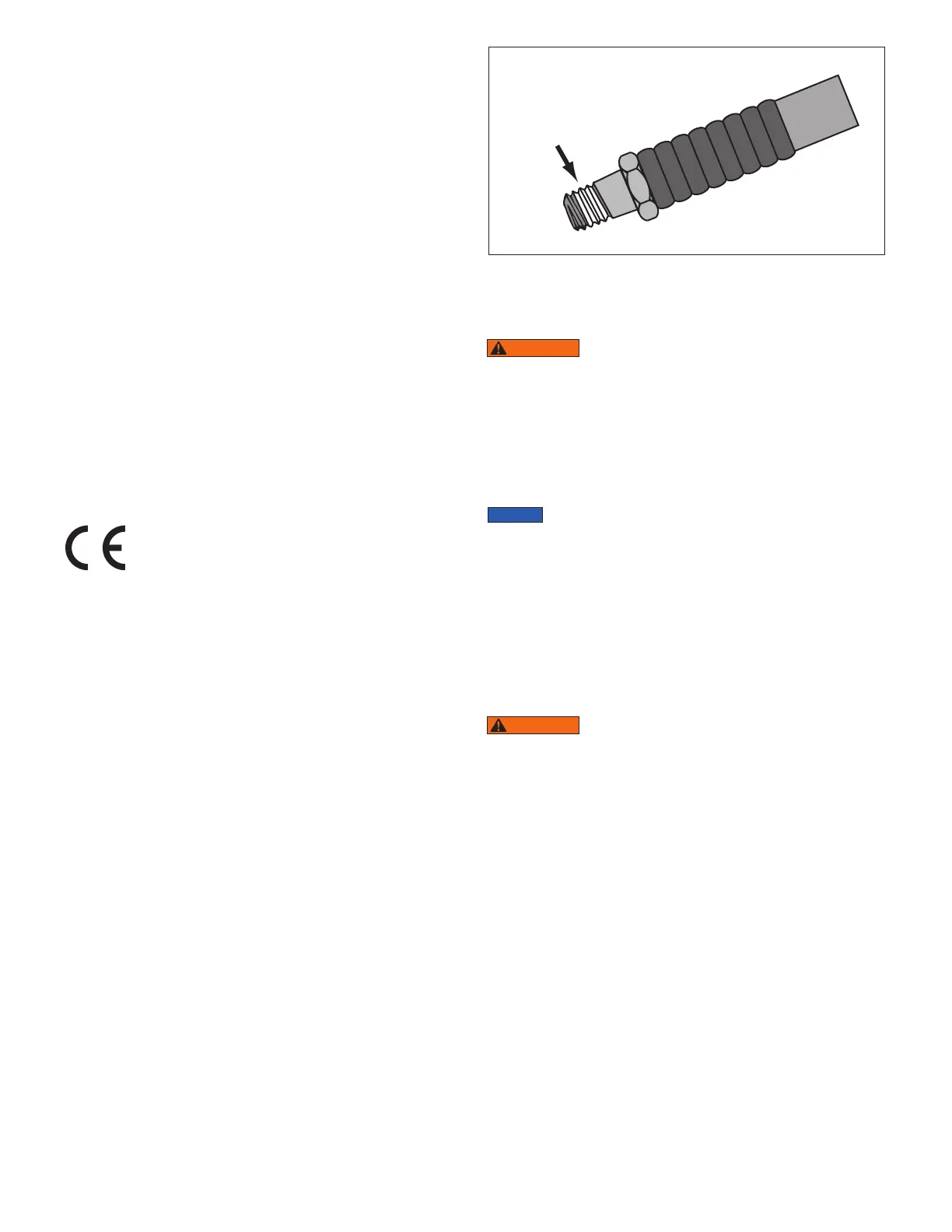

As hydraulic hoses, fittings and components are assembled,

apply 1-½ wraps of PTFE thread sealing tape to all threaded

NPT or NPTF fittings, leaving the first complete thread free of

tape as shown in Figure 3. Use care to prevent pieces of tape

from entering the hydraulic system.

Figure 3, Hydraulic Sealing Tape Application

All hoses, fittings and components used with the pump must be

rated for at least 10,000 psi [700 bar] operation.

WARNING

Avoid kinking or tightly bending hoses. Do not

exceed the hose manufacturer's stated minimum bend

radius. If a hose becomes kinked or otherwise damaged, it

must be replaced. Damaged hoses may rupture at high

pressure. Serious personal injury may result.

Hydraulic hose ports are located above the oil level indicator,

to the left of the control valve lever. See Figure 2, items 20 and

22. EP3404J models contain both “A” and “B” ports. EP3204J

models contain only port “A”. Both ports have 3/8" NPTF threads.

Hydraulic fittings, couplers and hoses are user-

supplied and not included with the pump.

Make hydraulic connections as described in the following steps:

1. To prevent the pump from starting, be sure that the pump

AC power cord is disconnected from the electrical outlet.

2. Relieve any residual trapped pressure BEFORE removing

the plug(s) from the pump hydraulic ports:

• EP3204J Models only: Move the valve lever fully counter-

clockwise to the “T” position.

• EP3404J Models only: Move the valve lever several times

back and forth between the “A” and “B” positions.

WARNING

A small amount of oil leakage or spray may

occur when plug is loosened in the following step. To prevent

eye injury, keep face away from this area when plug is

loosened.

3. Remove the plug from pump port “A” and pump port “B” (if

equipped).

4. As required, install hydraulic fitting(s) or coupler(s) in the

pump port(s). Tighten until finger tight. Then tighten an

additional 1.5 to 3.0 turns or torque to 40 ft. lb [54.2 Nm].

5. Make hydraulic hose connections as described for each

model:

• EP3204J Models Only: Connect the hose from pump port “A”

to the advance/retract port of the cylinder or tool.

• EP3404J Models Only: Connect the hose from pump port “A”

to the advance port of the cylinder or tool. Connect the hose

from pump port “B” to the retract port of the cylinder or tool.

• All Models: As required, install hydraulic pressure gauges

(user-supplied) in the system. Installation of a pressure gauge

in each hydraulic line is strongly recommended.

Loading...

Loading...