13

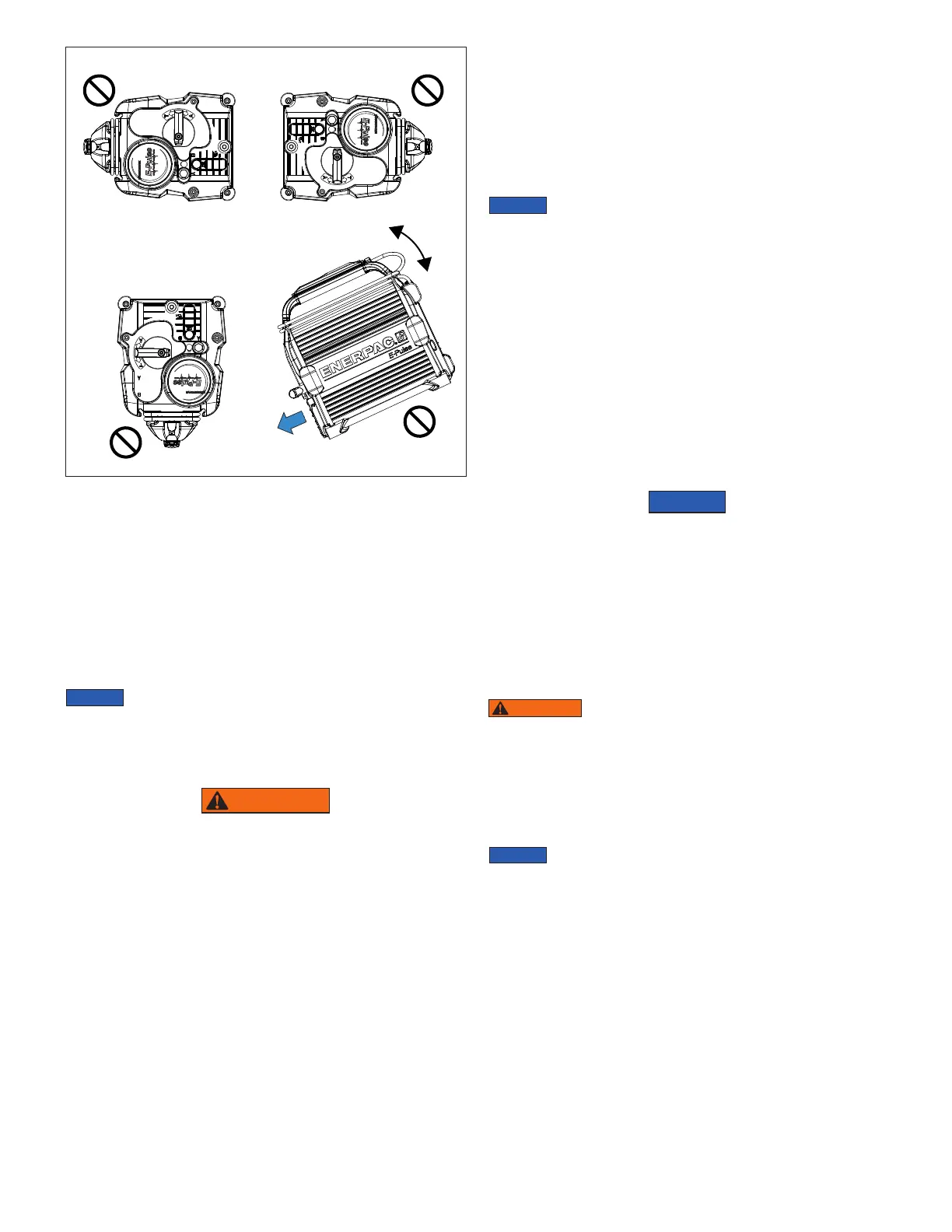

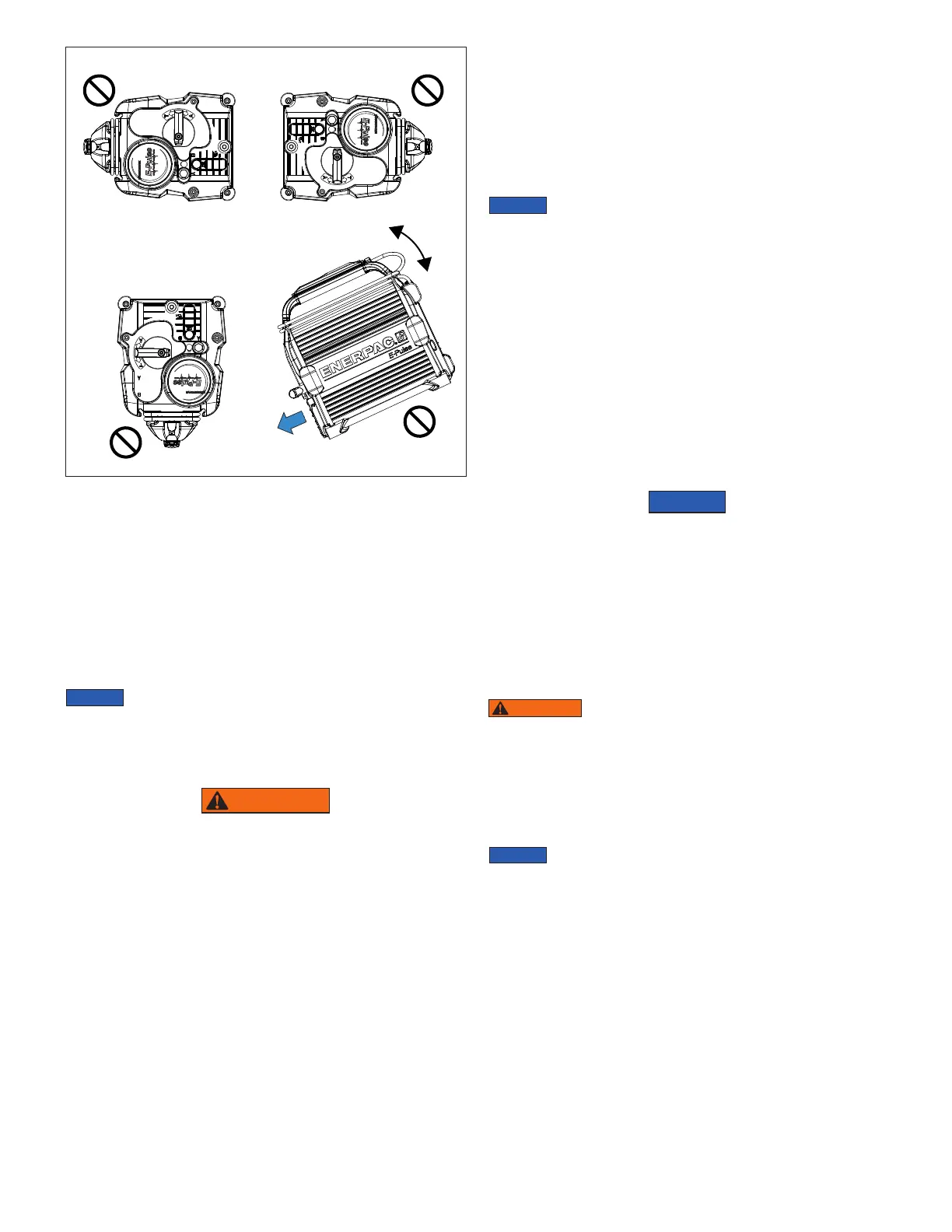

Figure 9, Pump Operating Positions - NOT ALLOWED

7.3 Air Removal

When hydraulic components are connected for the first time, air

may be trapped in the system. To ensure smooth, safe operation,

run the cylinder or tool through several complete advance-retract

cycles before placing the pump into service. Do this with no load

on the cylinder or tool and with the pump positioned higher than

the cylinder or tool.

When the cylinder or tool advances and retracts smoothly and

without hesitation, the air has been vented from the system.

If cylinder or tool fails to operate smoothly after being

cycled, perform the pump priming/air purging procedure. Refer

to Section 10.5.

7.4 Operating Precautions

WARNING

Failure to observe the following precautions and instructions

may result in death or serious personal injury

• Keep persons away from area under load during lifting,

lowering and whenever the control valve lever is moved.

• Continuously monitor the cylinder or tool being operated.

Be prepared to stop the pump immediately if a problem or

potentially dangerous situation occurs.

• Whenever possible, the pump speed should be set before

the pump is operated. Speed adjustments during operation

should be minimized so that the operator's complete attention

is focused on the lifting or lowering operation being performed.

• Never leave the pump running and unattended while it is being

operated in latched mode. When in latched mode, pump will

continue to run until stopped by the user or the 5 minute

automatic shut-o timer is activated.

• Because the time for the motor to stop can vary depending on

load conditions, the cylinder or tool may not stop advancing

immediately when the user releases the pendant jog button.

There may be a small continued movement of the cylinder or

tool while the motor is stopping.

• Avoid continuing to pressurize the cylinder or tool after it has

reached its maximum stroke.

7.5 Operation - EP3204J Models

Refer to Sections 6.3 and 6.6 of this manual for

detailed descriptions of the pendant controls and control valve

functions.

7.5.1 Advance - EP3204J Models

1. Be sure that the control valve lever is in the “A” position.

2. Start the pump. The cylinder or tool will begin advancing

immediately.

3. When the cylinder or tool has advanced the desired amount,

stop the pump. The cylinder or tool will stop advancing.

7.5.2 Release - EP3204J Models

1. Be sure that the pump is turned-o.

2. Slowly move the control valve lever to the “T” position to

retract the cylinder or tool. Moving the lever slowly will

reduce the risk of a lifted load dropping too rapidly.

• As needed, position the control valve lever in the flow metering

range to provide added control during the retract stroke

• Additional flow control devices (optional accessories - refer to

Enerpac catalog) may be required to more precisely control

the rate of retraction.

• Single-acting cylinders or tools not equipped with a return

spring may need to be manually retracted after all hydraulic

pressure is relieved.

7.6 Operation - EP3404J Models

WARNING

Under some conditions, the load could drop if

the control valve lever is moved between the “A” and “N” or

“B” and “N” positions while a load is present.

During lifting and lowering procedures, leave` the valve lever

in the “A” or “B” position so that the load is held when the

pump stops. Do not move the valve lever until the load is

removed or mechanically supported by stands, blocking,

hoist or other suitable means.

Refer to Sections 6.3 and 6.7 of this manual for

detailed descriptions of the pendant controls and control valve

functions.

7.6.1 Advance - EP3404J Models

1. Move the control valve lever to the “A” position

2. Start the pump to begin advancing the cylinder or tool.

3. When the cylinder or tool has advanced the desired amount,

stop the pump. The cylinder or tool will stop advancing.

4. Mechanically support the lifted load. Refer to Section 7.7.

5. Move the control valve lever to the “N” position.

7.6.2 Retract - EP3404J Models

1. Move the control valve lever to the “B” position.

2. Start the pump to begin retracting the cylinder or tool.

3. When the cylinder or tool has retracted the desired amount,

stop the pump. The cylinder or tool will stop retracting.

Loading...

Loading...