NOWPAK LINER-BASED CANISTER SYSTEM

7User Manual | Entegris, Inc.

REPLACEMENT BREAKSEALS

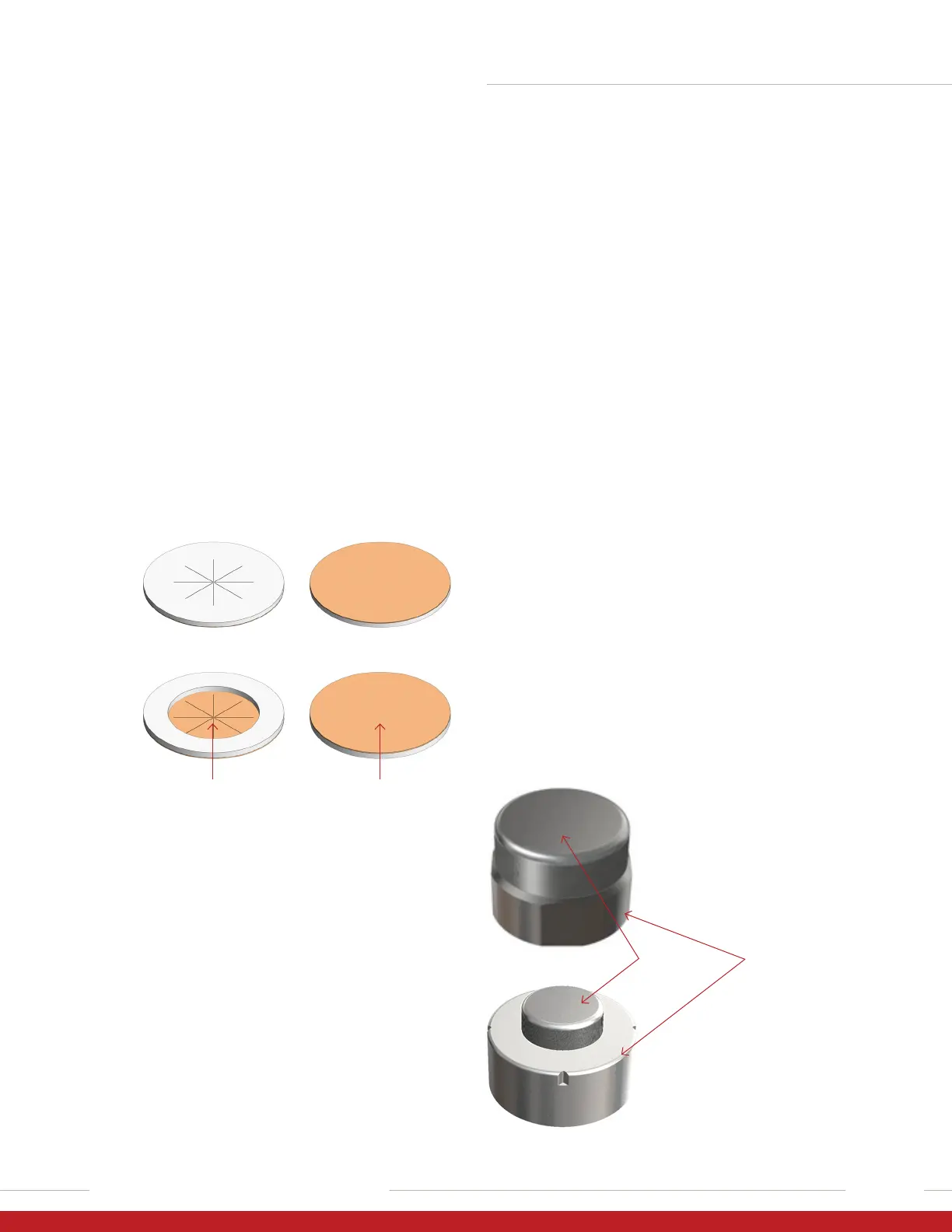

Breakseal technology, Figure 7, separates the chemical

from the environment to ensure absolute chemical

integrity during transport of filled canisters. When the

dispense connector is inserted into a canister at the

end user’s site, it punctures the breakseal and allows

access to the chemical stored inside the liner.

Breakseals are single-use only. Each time a chemical

supplier refurbishes a canister, a new breakseal is

inserted into the closure base before capping the

filled canister.

NOTE: All liner-based canister system canisters use a

breakseal, except the 63 mm neck thread type canisters

using the one-piece closure (item part number NC-W2).

These require an ND-LD or ND-HR dispense connector to be

attached directly to the canister after the closure has been

removed. See ND-LD Dispense Connectors on page 9.

This side faces upward

when installed in

the canister.

This side faces downward

in the canister and is

wetted by chemical.

NA-49 standard breakseal

NA-09 standard breakseal

Figure 7. Replacement NA-09 and NA-49 standard breakseals shown.

CANISTER CLOSURES

The chemical supplier uses a closure to seal the canister

after filling it with chemicals. At the end user’s site,

the closure cap is removed by hand and a dispense

connector is installed for drawing chemical from

the canister.

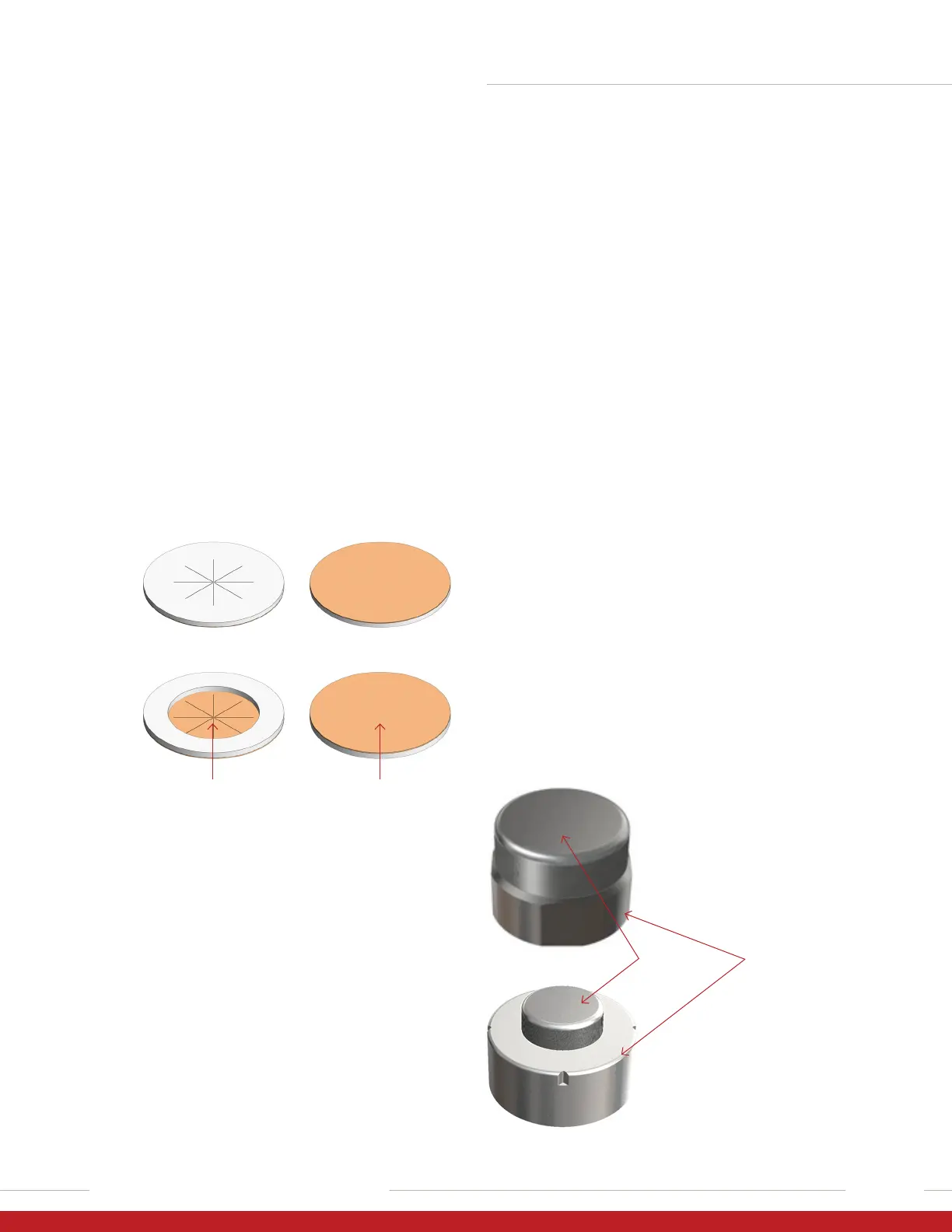

Canister closures are either two-piece assemblies or

one-piece.

Two-Piece Closures

Most canisters are sealed using a two-piece closure,

Figure 8. The closure base is torqued into place onto

the canister, and the closure cap is hand-tightened

onto the base.

The following two-piece closures are available for use

on liner-based canister system canisters, Figure 8:

• NC-03: anodized aluminum, 4- to 40-liter canisters,

2.5-12 UN neck thread, EPDM with PTFE coated

O-ring

• NC-03-2: anodized aluminum, 4- to 40-liter

canisters, 2.5-12 UN neck thread, FEP-encapsulated

O-ring

• NC-04: anodized aluminum, 4- to 40-liter canis-

ters, 63 mm buttress neck thread, EPDM with PTFE

coated O-ring

• NC-04-2: anodized aluminum, 4- to 40-liter canis-

ters, 63 mm buttress neck thread, FEP-encapsu-

lated O-ring

• NC-200-2: anodized aluminum, 200-liter canisters,

4.75-4 buttress neck thread, FEP-encapsulated

bottom O-ring

• NC-200-4: anodized aluminum, 200-liter canisters,

4.75-4 buttress neck thread, EPDM with PTFE

coated bottom O-ring

Each two-piece closure includes a closure base that

contains a compression ring and O-ring, and a closure

cap that contains another O-ring. See Appendix B:

Canister Compatibility Matrix, page 32, for information

on the thread specifications for each type of closure

base and cap.

Cap Closure base

NC-03/NC-04

NC-200-2/NC-200-4

Figure 8. Two-piece anodized aluminum closures.

Loading...

Loading...