Envent Engineering Ltd. Page 31 Revision 2.4

MAINTENANCE

The 330S/331S H

2

S analyzer will provide reliable service with very little attention. If

the analyzer is kept clean there should be no requirement to recalibrate from factory

gain settings. However, regular check-up (at least every three months) will ensure that

the analyzer is operating to specifications.

• Ensure that the H

2

S sensing tape take-up and feed reels are tight

• Ensure that the flow meters, humidifier tubing and sample chamber tubing are free

of liquid or particulate contamination. If the sample conditioning system is flooded

with liquid, refer to "Sample Conditioning System Cleaning Procedure" on page 32.

• Ensure there is enough H

2

S sensing tape, especially if a low H

2

S sensing tape

sensor is not installed. Refer to "H

2

S Sensing Tape Change Procedure" on page

31.

• Check the sample conditioning filter(s) every time the H

2

S sensing tape is

replaced. Replace the filter(s) as required.

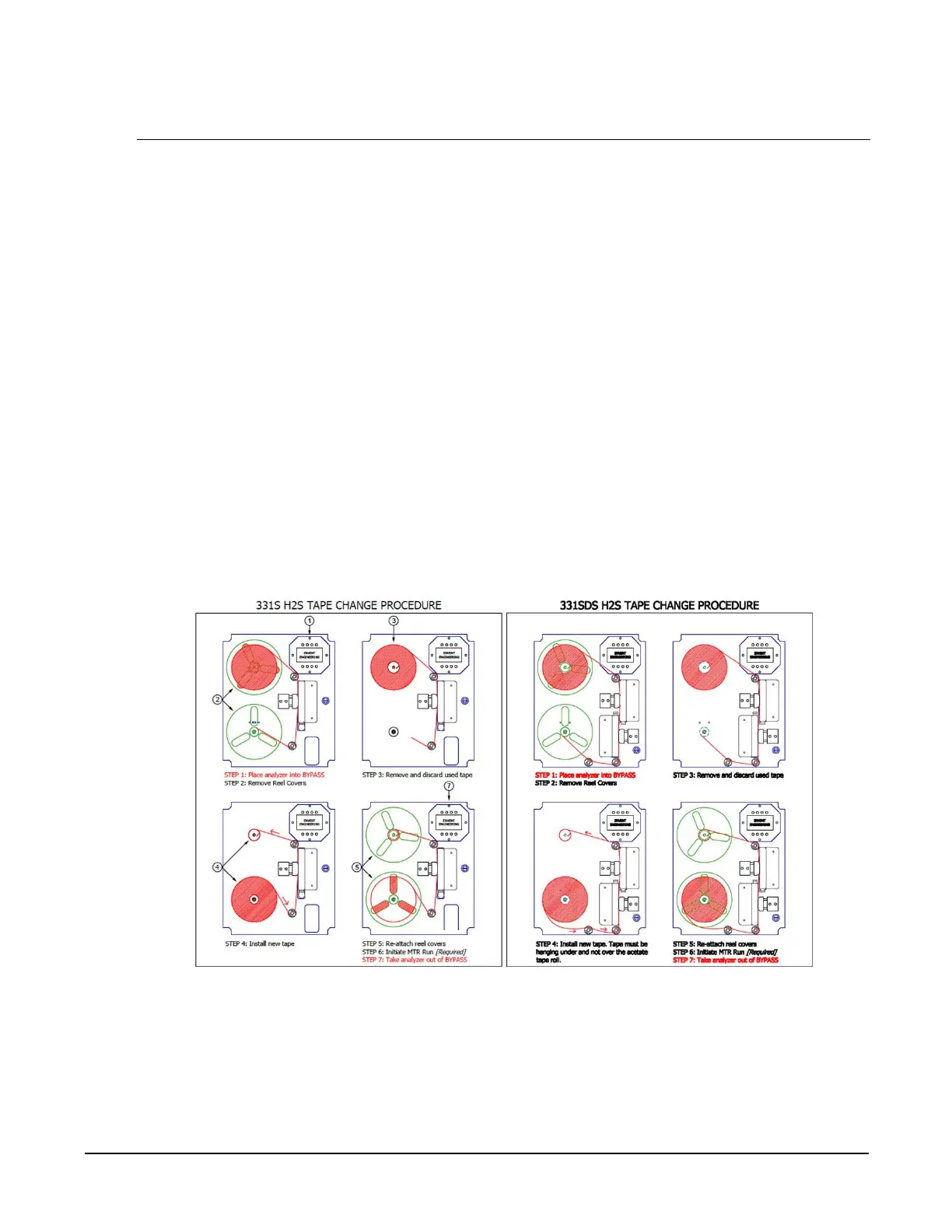

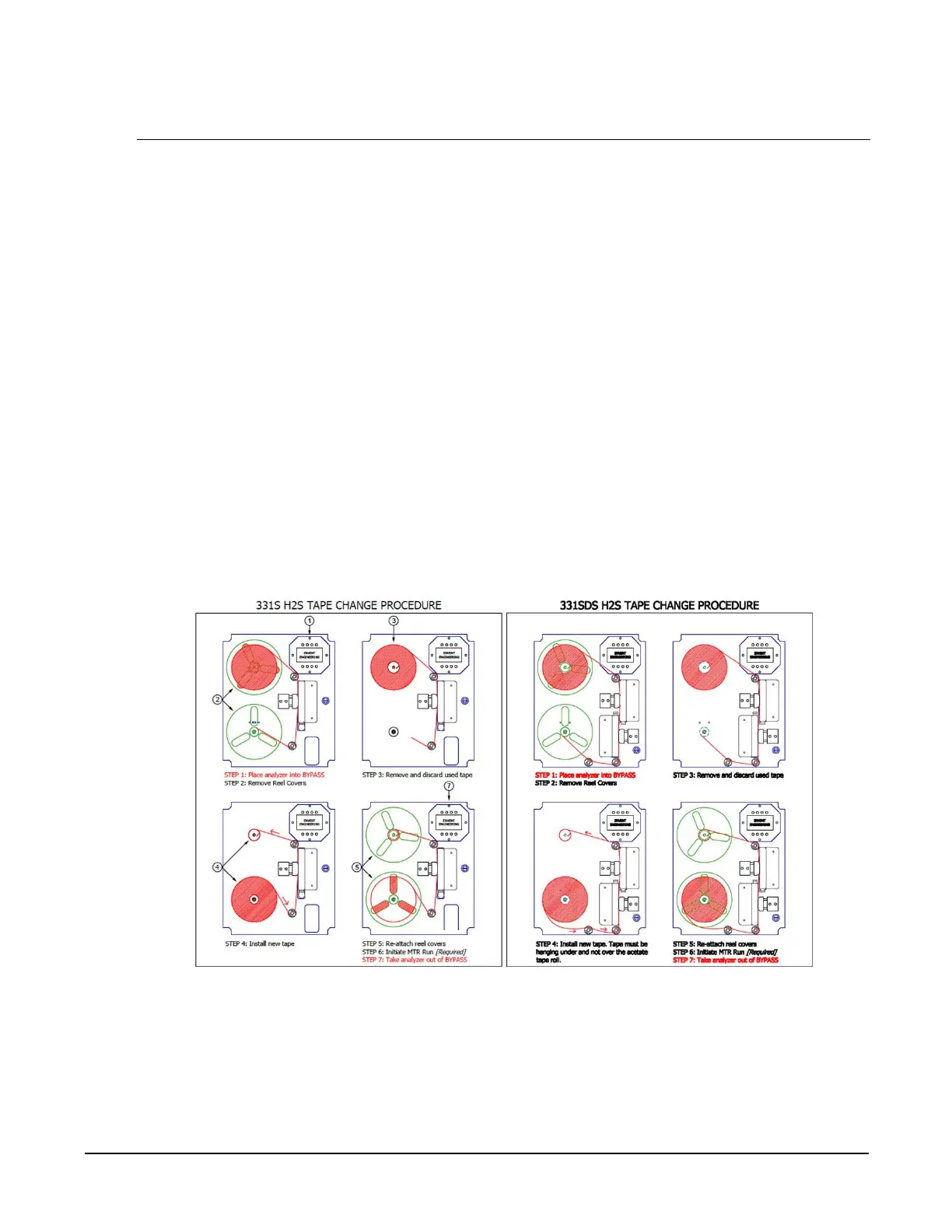

H

2

S Sensing Tape Change Procedure

Figure 11. 331S & 331SDS Sensing Tape Change

Procedure (Same as the 330S & 330SDS models)

Loading...

Loading...