Envent Engineering Ltd. Page 34 Revision 2.4

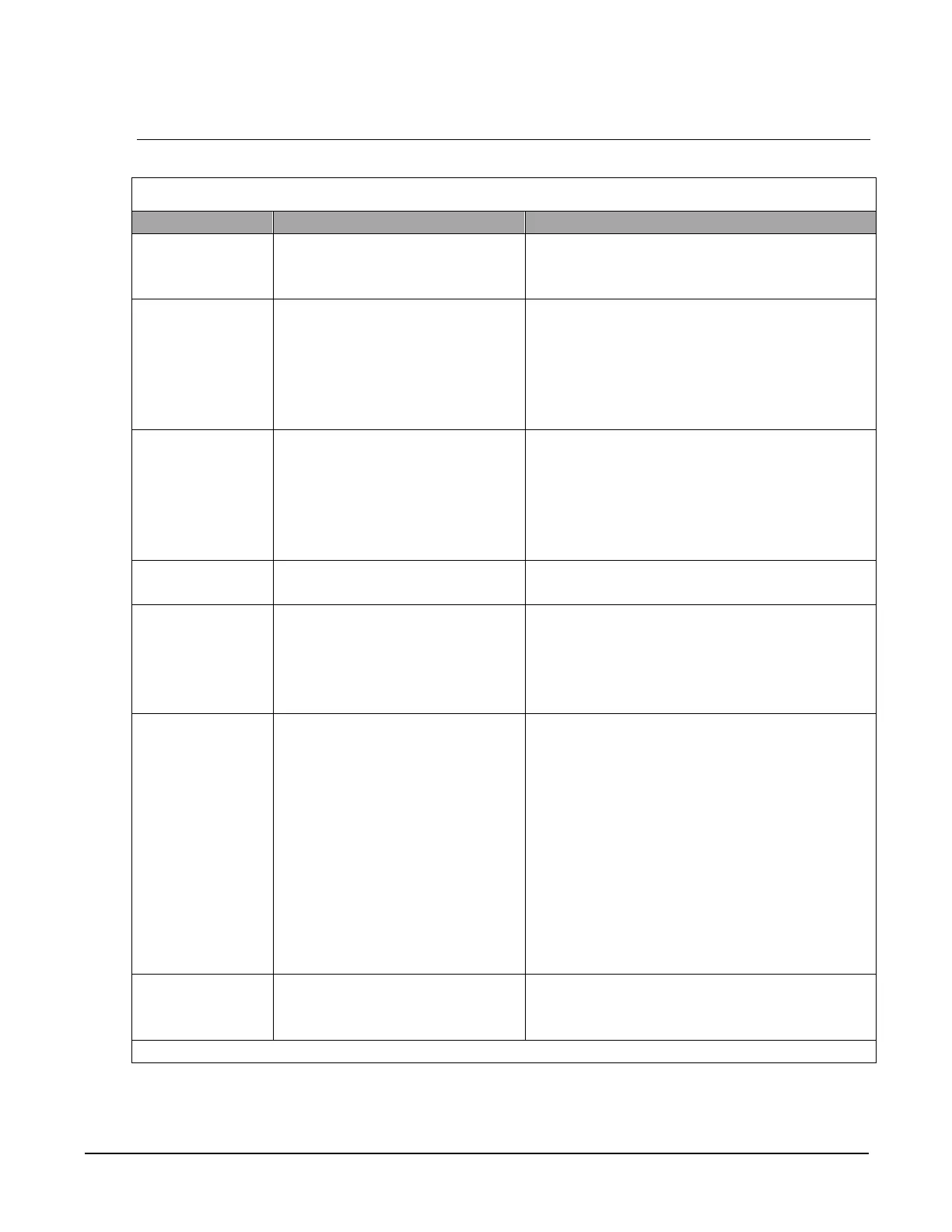

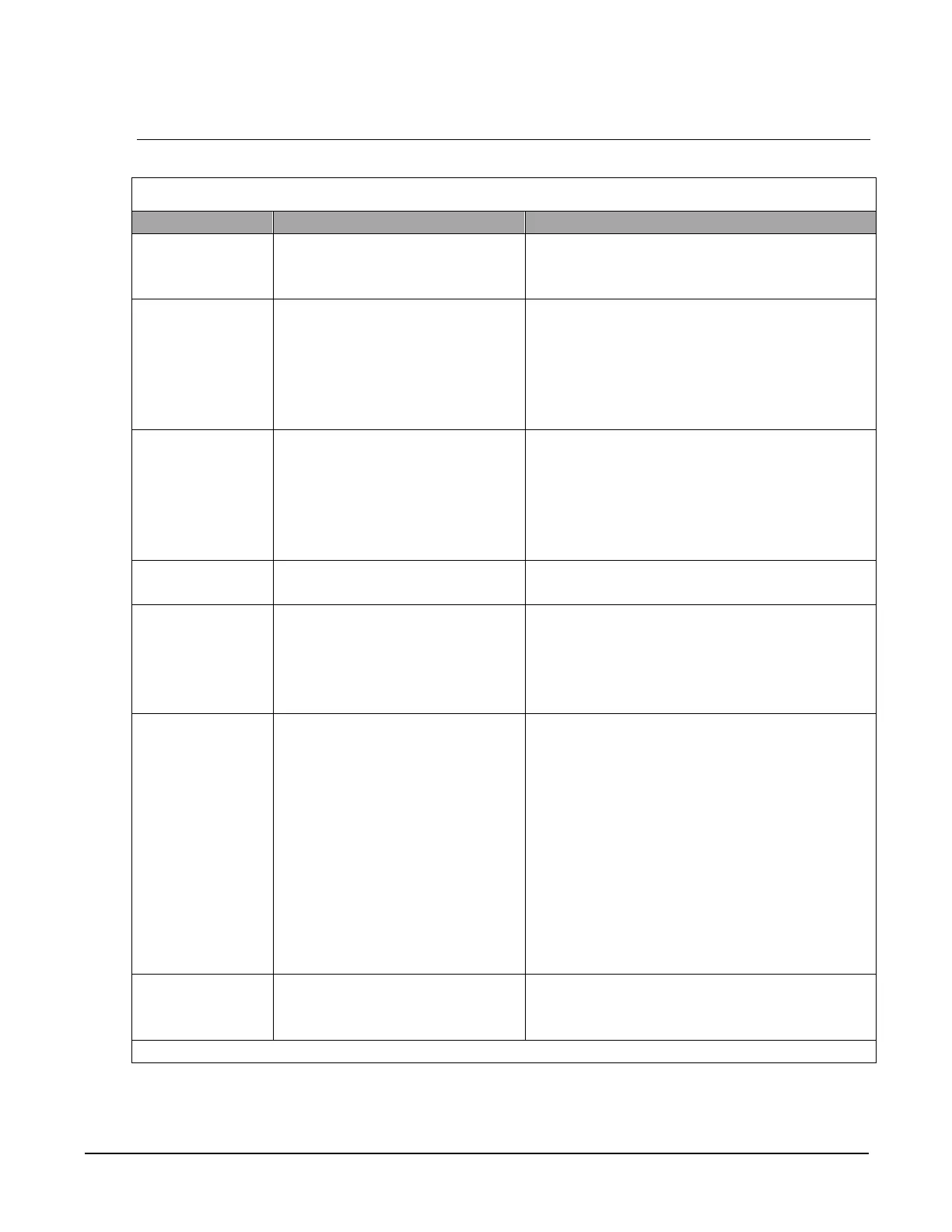

TROUBLESHOOTING

H2S Readings Issues

Erratic H2S

Readings

Trigger slide and H2S sensing

tape not seated properly

Ensure trigger slide and H2S sensing tape

are seated in the groove of the sample

chamber.

Pressure in building moving up

and down from fan, exhaust or

wind

The eductor should counteract this effect,

however, the eductor may be plugged or

vent blocked. Check there is no blockage

and that all vent tubing and fitting are 316

stainless steel, sized 3/8'' or larger on a

downward slope.

Sample vent/Eductor either

blocked or frozen

Check there is no blockage on the vent

and/or eductor. Check for vacuum in

Eductor block. Vent tubing and fittings

should be 316 stainless steel 3/8'' or larger

on a downward slope. Possible heat trace

required.

Analog input 2 jumper

removed

Re-install jumper in Analog Input across

(+4-20 & -4-20) on the controller board.

Sensor block fault Re-zero sensor block. Refer to "Re-zero

Sensor procedure" on page 29.

Check for green status led on sensor block

once procedure is done & proper mV on

white H

2

S sensing tape.

Sensor did not zero on white

H2S sensing tape

Check the H

2

S Sensing tape, if not properly

installed, refer to "H

2

S Sensing Tape

Change Procedure" on page 31 or on

sticker in the analyzer's door.

Perform a motor Run: Display>Press Menu

Button until "MTR Run">Press right button.

This will activate the motor and move the

H

2

S Sensing tape for a few seconds.

Re-zero sensor block if necessary. Refer to

"Re-zero Sensor procedure" on page 29.

Regulator not maintaining 15

psig (Changing flow rate to

analyzer)

Replace Regulator, Consult Envent

Engineering Ltd.

Continued on next page

Loading...

Loading...