Envent Engineering Ltd. Page 42 Revision 2.4

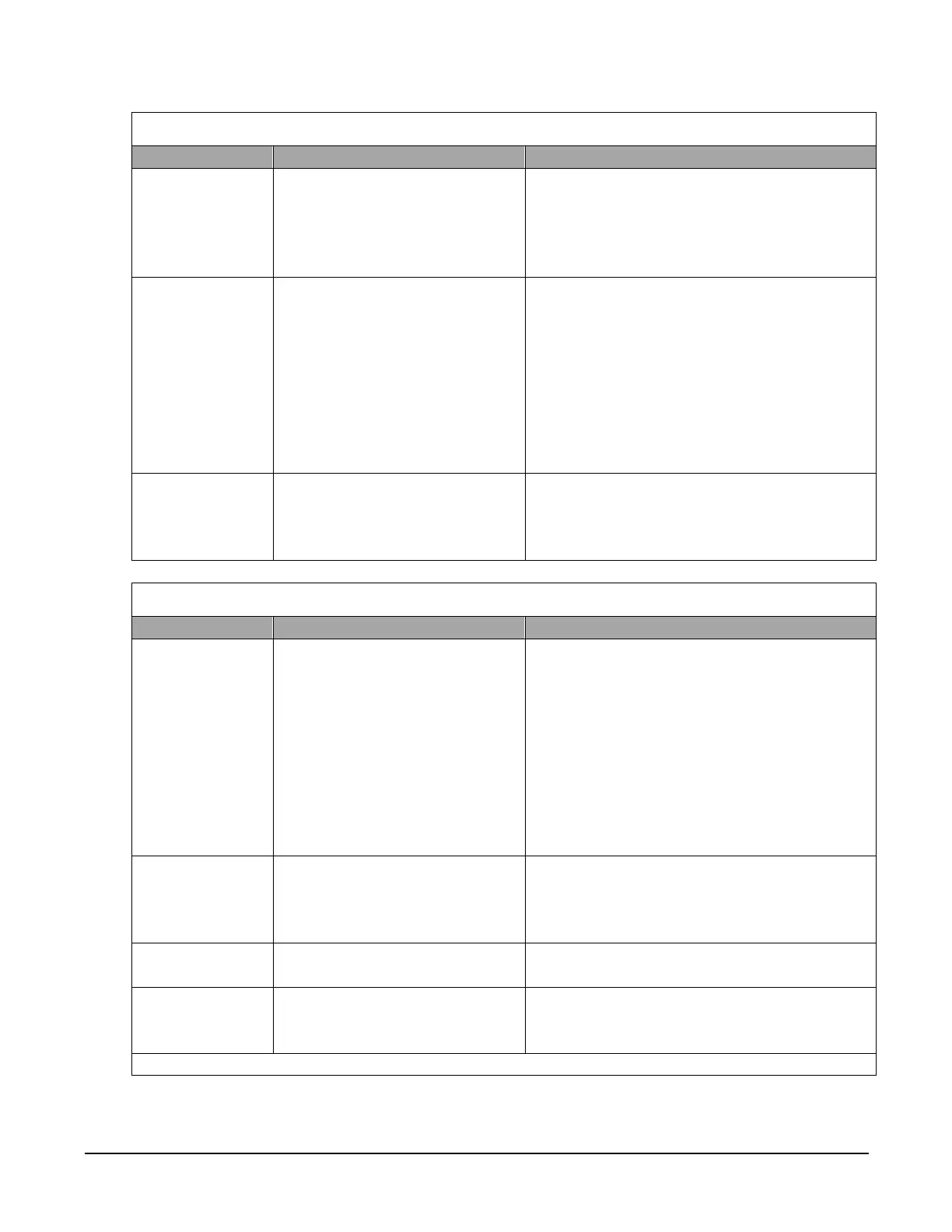

Electronics Issues (Cont’d)

The system variable for output

has been modified.

By factory configuration, the analog outputs

(1 & 2) are configured to output based on

H2S Sample 1. Make sure that if they are

modified, that the right system variables are

selected.

Not coming out

of alarm

Alarms are latched If alarms are latched, they need to be

acknowledged. Go to the display> cycle

through until "ACK" is reached> press the

right button to acknowledge all latched

alarms.

To deactivate the latching on any alarm,

use the ICE software, and connect to the

analyzer and de-select latching on any

alarm that is latched.

The analyzer is actually in

alarm

Make sure the alarm setpoint values are as

desired and that the analyzer is below (or

above – like temperature setpoint) those

setpoint values.

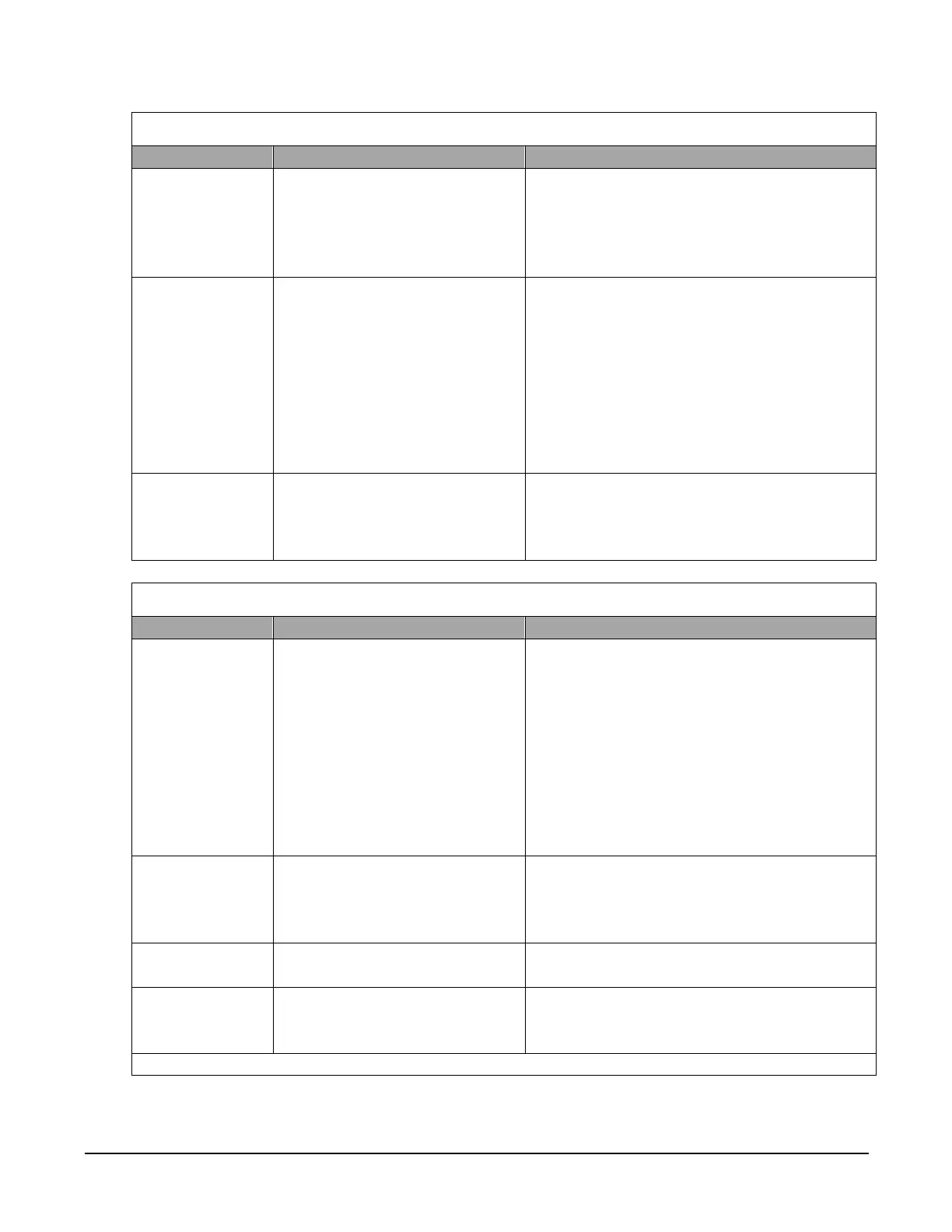

Sample Conditioning System Issues

Liquid Carried

over in SCS

Sample too wet for current

conditioning sample system.

If a one-time occurrence: Cleaning required

for sample system, refer to "Sample

Conditioning System Cleaning Procedure"

on page 32.

If more than one time occurrence: Sample

conditioning system may need a system for

wet/dirty sample gas (extra filters set as

coalescing, add liquid float stops, etc.).

Consult Envent Engineering Ltd.

Regulator not

maintaining 15

psi (erratic H2S

readings)

Problems with the Regulator

(over pressured)

Replace Regulator, Consult Envent

Engineering Ltd.

Liquid carried over into

regulator

Consult Envent Engineering Ltd.

Problems with the (50 psi)

sample pre-regulator at the

sample point.

Heated regulator may be required if liquid

hydrocarbon carry over is present at the

pre-regulation sample.

Continued on next page

Loading...

Loading...