Confidential

TITLE

SHEET

REVISION

NO.

NEXT

SHEET

A

6 5

TM-L90

Roll Paper

Manufacturing Guide

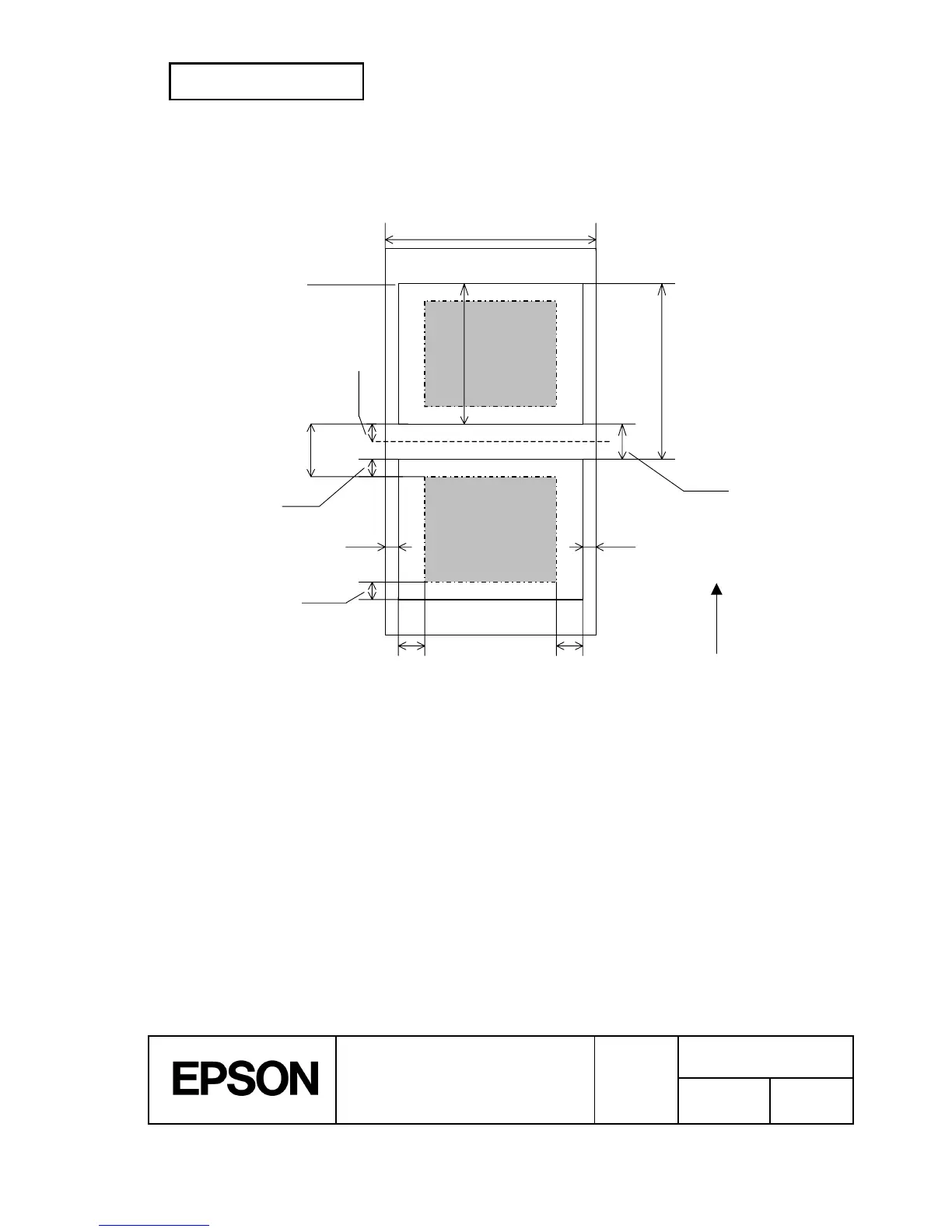

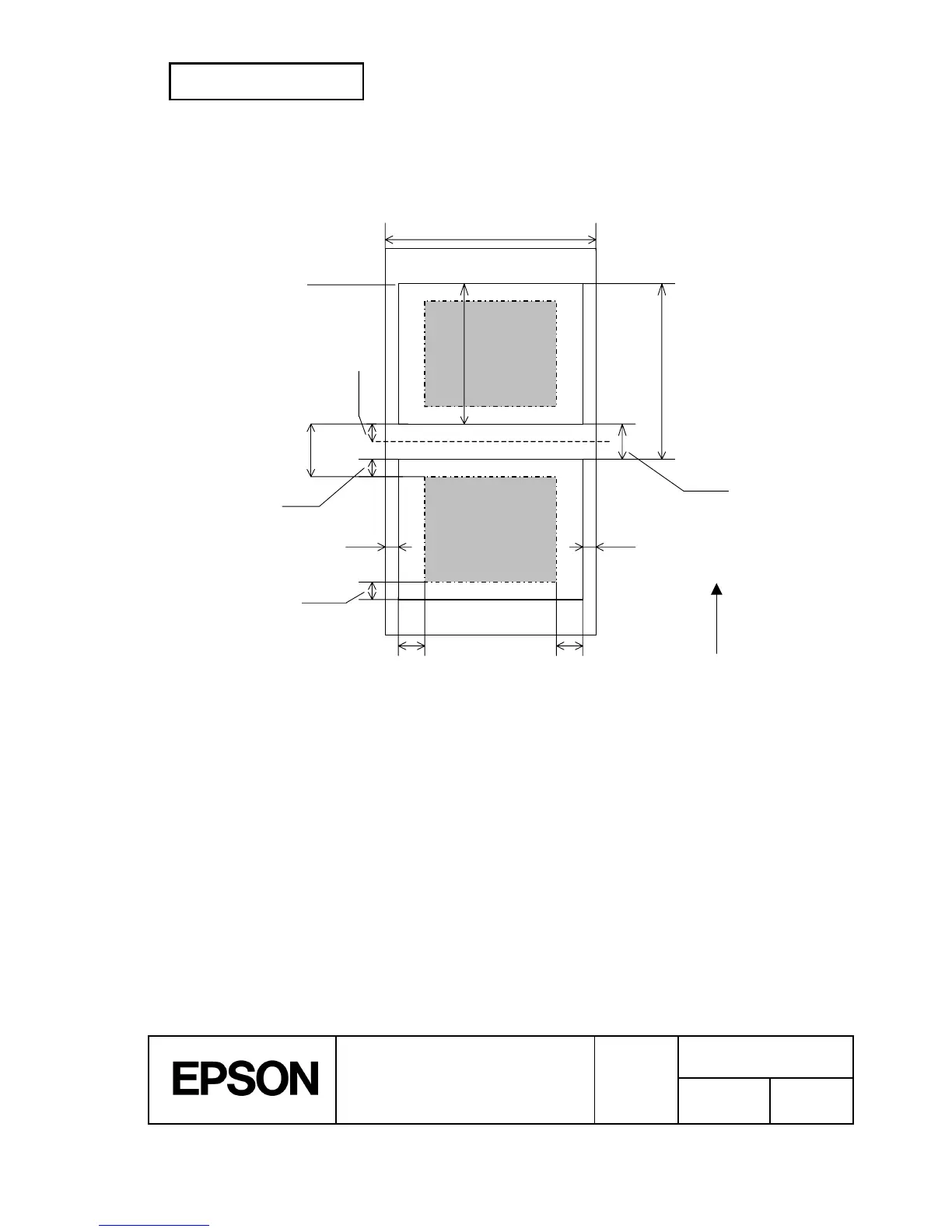

3.6 Requirements for Die-Cut Label Size

When manufacturing die-cut label paper (with or without black marks), be sure that the paper

meets the following requirements. (The ESC/POS commands expands the settable range,

omitting the margin settings or the limitation on use (NOTE 2 of Section 3.6).)

Face stock (printing face)

Paper feeding

direction

37.5 ± 0.5 ~ 69.5 ± 0.5 or 79.5 ± 0.5

Label interval L1:

30.4 ~ 106.6

L

2 = 5 ± 0.5

1.5 or more

1.5 or more

1.75 ± 0.5

Cutting position

1.75 ± 0.5

2.8 or more

(Label length:

25.4 ~ 101.6)

L

3

L4

(Printable area)

Corner R2 or less

2.8 or more

[Units: mm]

Label Size Requirement

NOTES: 1. Be sure to set the cutting position (L

4

) between labels.

2. Since the position of the print head and the cutter is not contiguous, the printer

operates as follows when the paper is cut:

1 Completes printing

2 Feeds the paper to the cutting position

3 Cuts the paper

4 Feeds the next label in reverse to the print starting position

Depending on the paper setting or the paper size, the tip of the next label may be

fed over the print head in action 2 above, or the paper may be fed incorrectly or

jammed by catching the tip of the next label with the print head in 4.

To avoid this, be sure that the distance from the cutting position to the print

starting position (=L

3

–L

4

) is 3.6 mm {0.14"} or more. And the minimum label

length must be 25.4 mm {1"}.

If (L

3

–L

4

) is less than 3.6 mm or the label length is less than 25.4 mm, the paper

may be fed wastefully because action 4 is not performed.

Loading...

Loading...