-- 1 0 --

cga9d1ea

OPERATION

The joint tracking equipment is adjustable for different kinds of joint tracking, such as

tracking by sensing the edge and tracking by sensing the groove. The adjustment is made both

on the control box and on the sensor.

S Joint tracking by sensing the edge:

Set the selector switch on the control box to or depending on whether the de-

sired sensing direction is left or right. The two stop screws shall be screwed home, see

figure on page 7. This means that the sensor fingers are laterally spring--loaded and thus

permit edge sensing. Joint tracking by sensing the edge is used for fillet j oints and similar

joints, see also table below.

S Joint tracking by sensing the groove:

Set the selector switch on the control box to

or depending on whether vertical

and horizontal sensing is desired or vertical sensing only. The two stop screws shall be

screwed out at least two turns or to stop, see figure on page 7. T his will disengage the

spring--load of the sensor fingers and permit groove sensing. If the stop screws are not

screwed out there is a risk that the sensor fingers start ”climbing” the joint walls of shal-

low V and U joints. See also joint table below for correct settings.

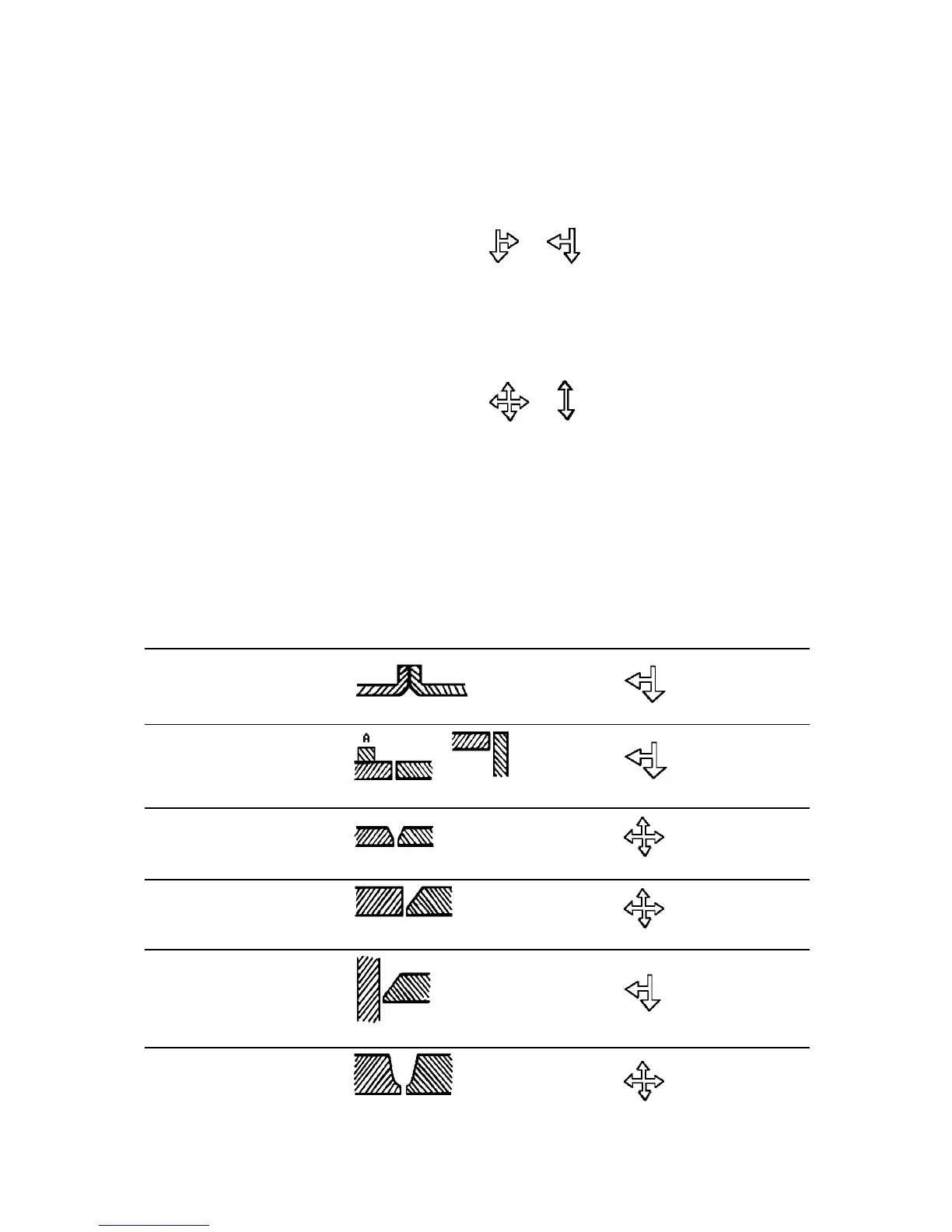

Examples of some different types of j oints and of the guide f inger angle against the

guiding edges.

Joint type Settings, control box

Double--flanged butt joint

I--weld

A=Guide bar

V--weld

1/2 V--weld

1/2 V--weld

U--weld

Loading...

Loading...