Do you have a question about the Esko Kongsberg XL and is the answer not in the manual?

Outlines responsibilities of manufacturer, owner, and operators.

Lists mandatory operator qualifications and knowledge.

Clarifies intended versus non-intended uses and their consequences.

Explains various warning symbols and their meanings.

Highlights specific areas requiring caution and attention.

Describes essential safety features like E-stops and DynaGuard.

Recommends necessary personal protective equipment for operators.

Provides guidance on handling system malfunctions.

Lists essential checks before starting machine operations.

Identifies remaining potential risks despite safety measures.

Step-by-step instructions for powering up the system correctly.

Step-by-step instructions for properly powering down the system.

Explains how to set the main reference point within the iPC software.

Describes the process of creating a new job from a file.

Guides users through the production setup parameters.

Details the steps for executing a prepared job.

Covers the process of milling production, including pre-execution checks.

Provides guidelines for cutting materials with significant thickness.

Covers performing operations on both sides of a material.

Guides users on using various reference point configurations.

Details how to establish the main reference point for operations.

Explains reference points and their role in the coordinate system.

Explains how to adjust the active tool using wizards.

Details the procedure for calibrating the tool height.

Explains how to set lag settings for rotating tools.

Guides users on adjusting the rotation of rotating tools.

Explains how to adjust the center offset for tools.

Provides guidelines for handling and maintaining tools properly.

Details the FlexiHead tool head and its description.

Describes the PowerHead tool head and its features.

Details the V-notch Knife and its mounting.

Details the Bevel Knife 45 for angled cuts.

Introduces the MultiCUT tool head and its specifications.

Highlights safety concerns related to unattended operation and dust removal.

Lists precautions for taking care of the milling spindle.

Offers advice for obtaining optimal milling results.

Details procedures for inserting and replacing milling bits.

Provides procedures for changing and cleaning the chuck.

Addresses issues of bit slipping and chuck replacement.

Covers tool adjustments for milling units, including height and offset.

Describes the functions and usage of the measuring foot.

Covers the X-Pad device and its calibration.

Details the procedure for calibrating the X-Pad.

Describes the Bevel Knife tool for angled cuts and blade replacement.

Explains the Braille Tool for creating braille signage.

Explains the location and replacement of MPU fuses.

Details the location and replacement of X1 amplifier fuses.

Details the location and replacement of X2 amplifier fuses.

Explains the location and replacement of Y/Z amplifier fuses.

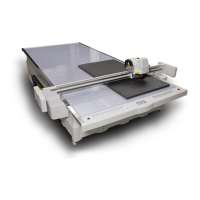

| Brand | Esko |

|---|---|

| Model | Kongsberg XL |

| Category | Power Tool |

| Language | English |