driveways to clear snow while leaving gravel

undisturbed.

Normal – Allows the tracks to be suspended

independently for continuous ground contact.

Deep Cutting – Locks the front end of the snow

thrower down to the ground for had-packed or icy

snow conditions.

Adjustments

Skid Shoes

Position the skid shoes based on surface

conditions. For removal of snow in normal

conditions, such as a paved driveway or sidewalk,

place skid shoes in the higher position to give a

3mm (1/8”) clearance between the scraper blade

and the ground. Use a middle or lower position

when the area to be cleared is uneven, such as a

gravel driveway.

It is not recommended to operate the

snow thrower on gravel as it can easily

pick up and throw by the impeller, causing

personal injury or damage to the snow

thrower and surrounding property.

If you choose to operate the snow thrower on a

gravel surface, use extra caution and keep the

skid shoes in position for maximum clearance

between the ground and the scraper blade.

Always adjust skid shoes after adjusting

scraper blade to prevent premature wear

to scraper blade or damage to auger

housing.

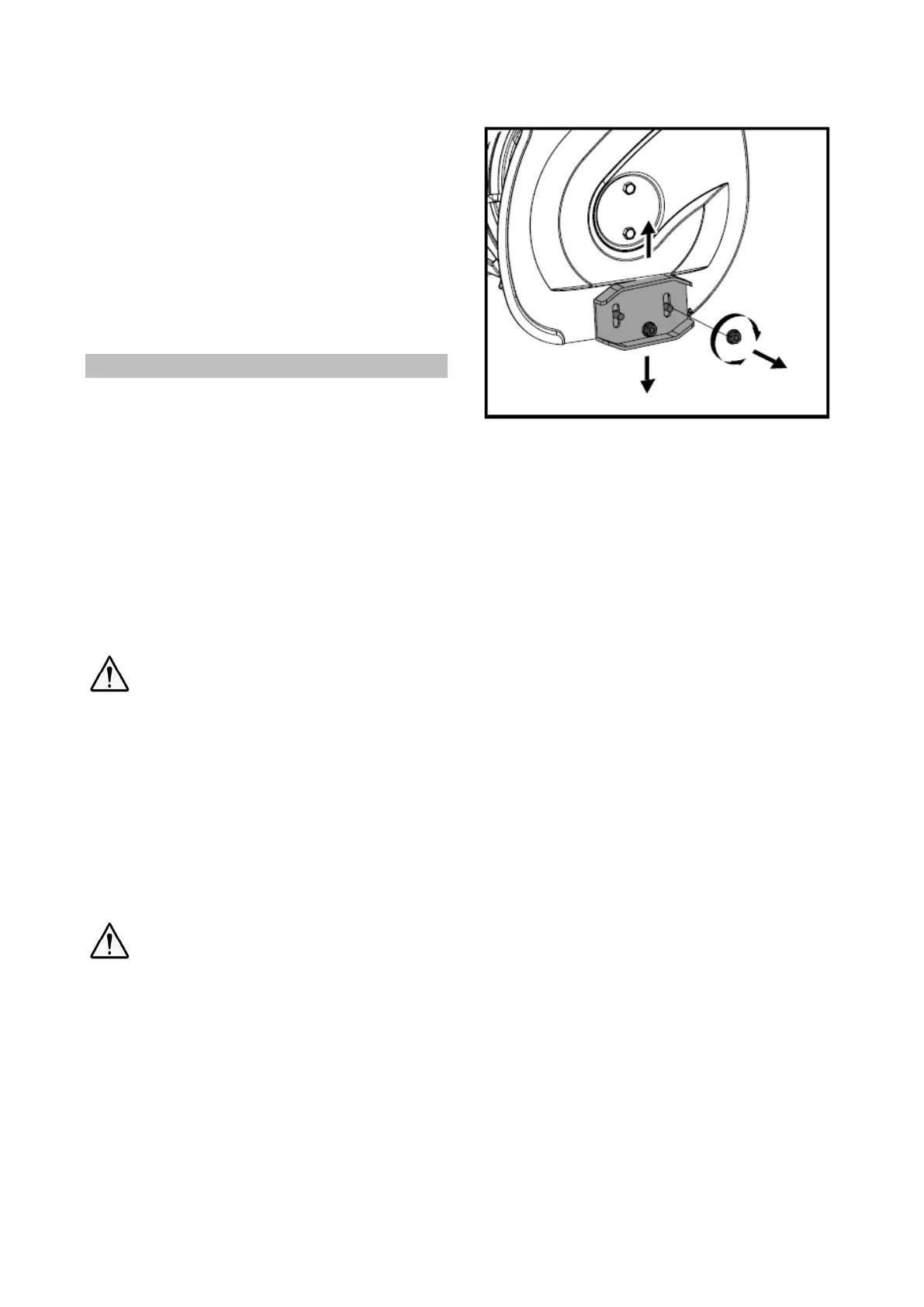

To adjust the skid shoes:

1. Loosen the four hex nuts (two on each side)

and carriage bolts. Move skid shoes to

desired position.

2. Make sure the entire bottom surface of skid

shoe is against the ground to avoid uneven

wear on the skid shoes.

3. Retighten nuts and bolts securely.

Auger Clutch and Drive Clutch

When the auger clutch lever or drive clutch is

released and in the disengaged position, the

cable should have very little slack. It should bolt

be tight.

Auger must stop within 5 seconds when the auger

clutch lever is released. If auger clutch does not

engage or disengage properly, adjust auger

clutch before operation.

If the snow thrower’s drive is disengaging

intermittently during operation, or it drives when

you release the drive clutch lever, adjust the drive

clutch before operation.

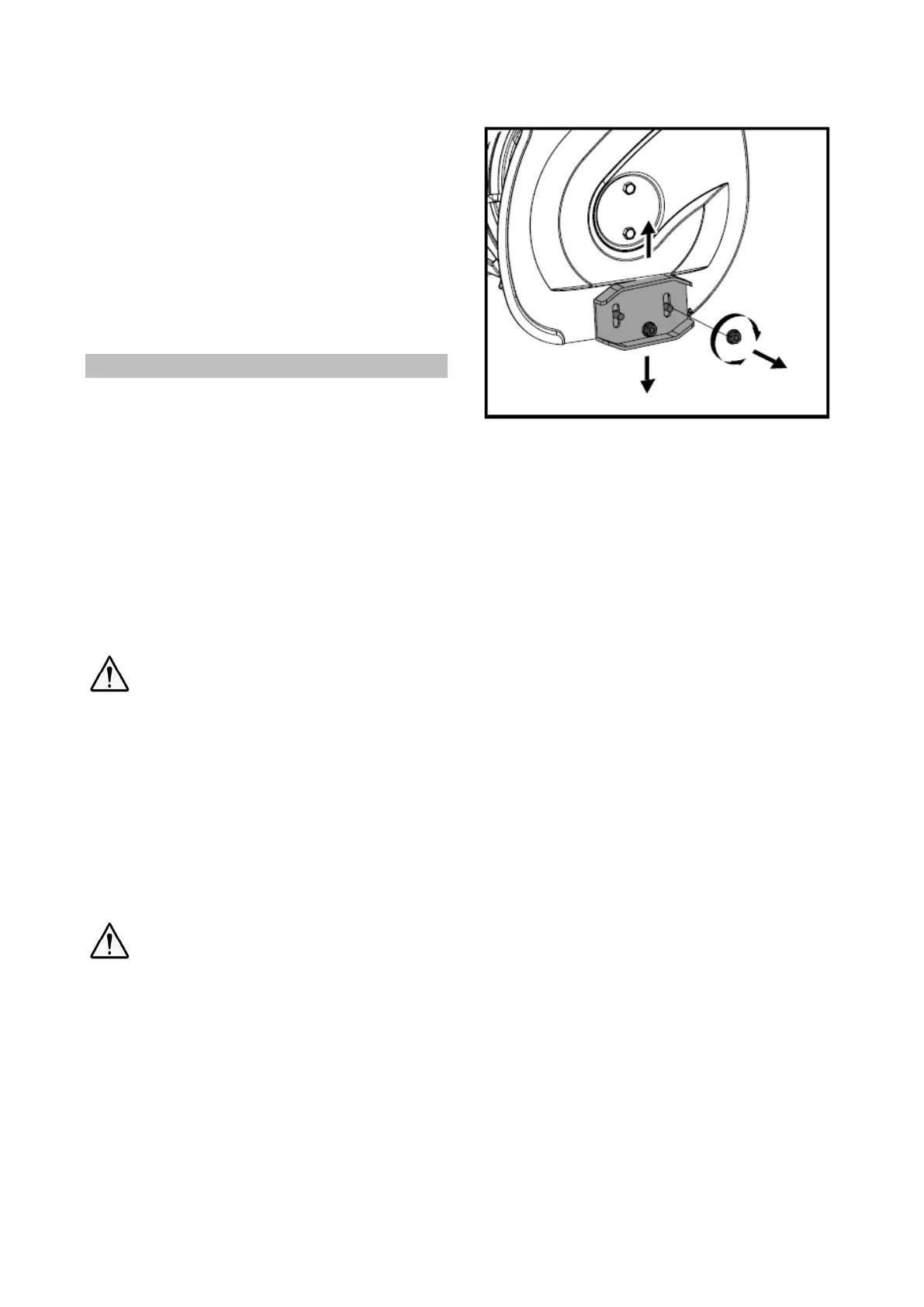

Both auger clutch and drive clutch can be

adjusted at either end of their control cables.

Loosen adjusting nuts on cable support bracket.

1. Slide the control cable up or down by

threading adjusting nuts to increase cable

tension or provide more slack.

2. Thread the adjusting nuts to slide the cable

down or up to increase tension or provide

more slack.

3. Tighten nuts after proper adjustment is

Loading...

Loading...