Etrel Inch Lite | User Manual

|

and recycle them responsibly to promote the sustainable reuse of

material resources.

Household users should contact either the retailer where they

purchased this product, or their local government office, for details of

where and how they can take these items for environmentally safe

recycling.

Business users should contact their supplier and check the terms and

conditions of the purchase contract. This product and its electronic

accessories should not be mixed with other commercial wastes for

disposal.

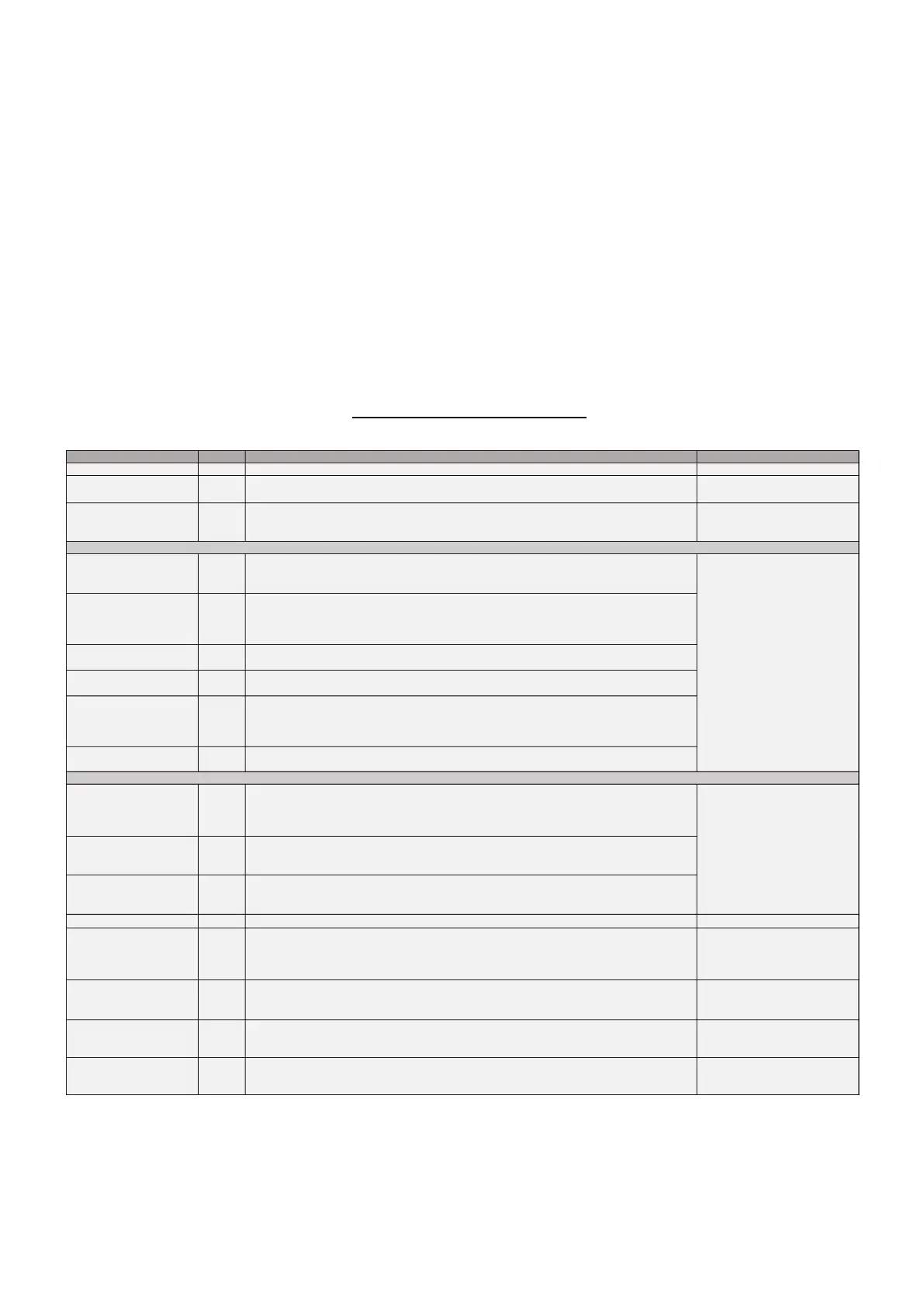

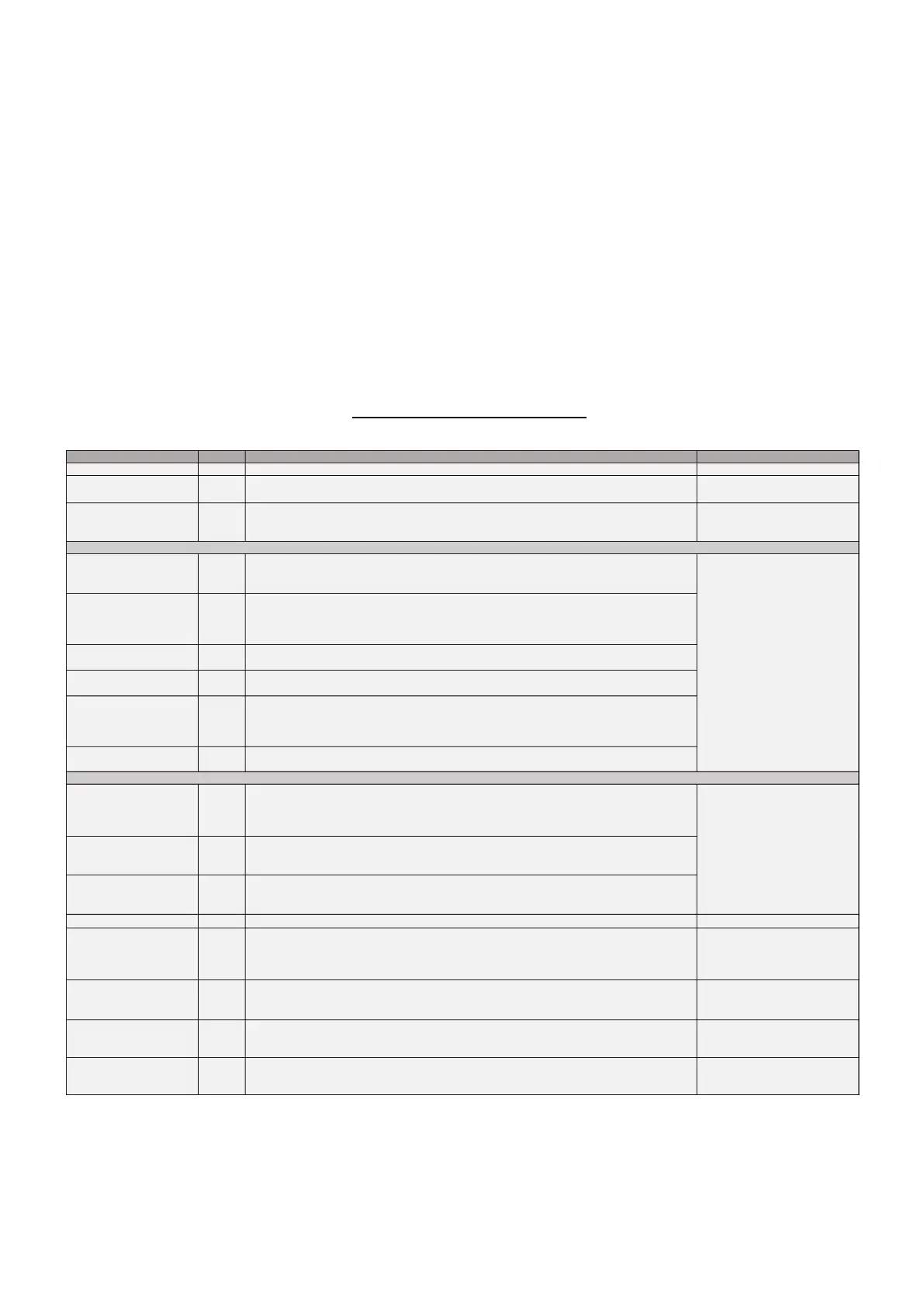

SAFETY RISK ANALYSIS

DANGER OR RISK RELEVANT IN ACCORDANCE WITH

Preliminary observations YES CENELEC Guide 32

Safety integration YES CENELEC Guide 32

General YES

EN 61851-1:2001, EN 61851-1:2011,

EN 61851-1:2019, EN 61851-21:2002, EN

61851-22:2002

++ VSE VERZIJE

Leakage current YES

Energy supply YES

Stored charges YES

Arcs YES

Electric shock YES

Burns YES

Instability YES

Break-down during operation YES

Ingress YES

Falling or ejected objects NO /

YES

Directive LVD 2006/95/ED (through

April 19, 2016) and Directive 2015/30/EU

(from April 20, 2016)

YES IEC 60335

Vibration YES IEC 60335

Improper fitting of parts YES IEC 60335

Application of Annex A of CENELEC Guide 32, Safety aspects relating to low voltage equipment, in particular the "3-

step-method": 1) Inherent design measures, 2) Techical safety measures, 3) Information for use.

Overload and short-circuit protection is ensured with use of suitable MCB. Additional surge protective device could

be required by national legislation. Protective devices can be installed either in charger, or in an installation

upstream. Coordination and selectivity of protection devices with upstream devices should be ensured, so that

only the protection device, the closest to the fault, operates.

Electrical burns and other injuries are prevented with use of appropriate protective devices, properly designed

insulation and prevention of arcs.

To prevent leakage currents, the suitable RCD protection device is used either in charging station, or in an

installation. Each socket must be protected by individual RCD. The power supply was selected to have a negligible

leakage current.

The use of quality housing with use of additional structural supports ensures high resistance on mechanical stress.

The proper installation of mounting anchor ensures that the charger is rigidly supported and can not turn over.

Our charging stations are tested to determine the IK code (degree of protection provided by enclosure) in

combination with tests to determine IP code (ingress protection).

The use of quality housing with use of sealing foam and filters ensures high resistance to ingress of particles. Our

charging stations are tested to determine the IP code (ingress protection) in combination with tests to determine IK

code (degree of protection provided by enclosure).

The only moving part representing the hazard is the opening and closing of the doors. The doors should be closed

only if there is nothing blocking them (either mechanical object, or human hand). This risk is also mitigated with the

explanation in the user and installation manual.

There is a possibility that sharp edges occur during the production process during the cutting and assembly of the

housing. For this reason, possible sharp edges that could harm a person, were identified and are grinded away

after the assembly. The wires are also protected so that they do not come into contact with the remaining sharp

edges. Proper processing, finishing and coloring procedures of the surfaces ensure high quality product.

The components are dimensioned in such a way that they cannot cause a charge that would be hazardous to

human health. In case of vehicle malfunction, the possible hazard of stored charge is mitigated by the use of RCD.

The major concern with vibrations is the loosening of electrical connections. For this reason, special care is made

during the production process to use the optimum torque and tightening sequence for fasteners with use of tools

with settable screwing torque.

Moving parts, especially where

there may be variations in the

rotational speed of parts

The tolerances of parts are high enough to not represent a problem during the manufacturing process. In addition,

the manufacturing instructions are covering all possible improper fittings of connectors and other components. All

charging stations are put on the testing line after assembly where possible improper fitting would be identified.

Basic protection is provided with selection of appropriate insulation of all components and in addition live parts

are not accessible during charging. Fault protection is achieved with earthing of all exposed conductive parts and

with automatic disconnection of the supply in case of a fault. Additional protection is also provided, with use of

high sensitivity RCD's.

The use of suitable switching and protective devices ensures that possible arcs are extinguished quickly and

without causing damage.

Sharp edges or corners and

inadequate surfaces

Directive LVD 2006/95/ED (through

April 19, 2016) and Directive 2015/30/EU

(from April 20, 2016),

EN 60947-1:2007, EN 60947-2:2006,

EN 60947-3:2009, EN 60947-4-1:2010, EN

61008-1:2004, EN 61008-1:2012,

EN 61009-1:2004, EN 61009-1:2012,

EN 60309-1:1999, EN 60309-2:1999,

EN 60947-1:2007, EN 60947-2:2006,

EN 60947-2:2017, EN 60947-3:2009,

EN 60947-4-1:2010, EN 62196-1:2012, EN

62196-1:2014, EN 62196-2:2012,

EN 62196-3:2014, EN 50065-1:2011,

EN 50065-4-2:2001, EN 60950-1:2006, EN

50065-4-7:2005, IEC TS 61439-7:2018,

IEC Guide 116:2018, ISO/IEC Guide

51:2014

EN 62262:2002, EN 60529:1991

Protection against electrical hazards

Protection against mechanical hazards

Application of Annex A of CENELEC Guide 32, Safety aspects relating to low voltage equipment.

Charging station complies to all requirements of the standards of the EN 61851 family, to all parts relevant to AC

conductive charging and is compliant to all versions, current and old. This family of standards covers requirements

for charging stations from all aspects, however some details are covered in other standards, as listed in this table.

Charger construction ensures that break-down during operation is not possible in normal conditions. This would

be possible only with high enough external force, e.g. vehicle collision. For this reason the recommendation for

public charging stations is to use protective bollards.

Loading...

Loading...