Assembly and Installation | 25

13. When mounting to a steel pit and steel raised floor, a #7 drill bit for

tapping or a 9/32 drill bit to create through holes is required when

mounting anchor plates to the steel raised floor. Locate and mark holes

in each group of anchor plates. Drill and tap or drill through each hole

and then screw in 1/4–20 hardware so that the turntable does not move

as you go around each location.

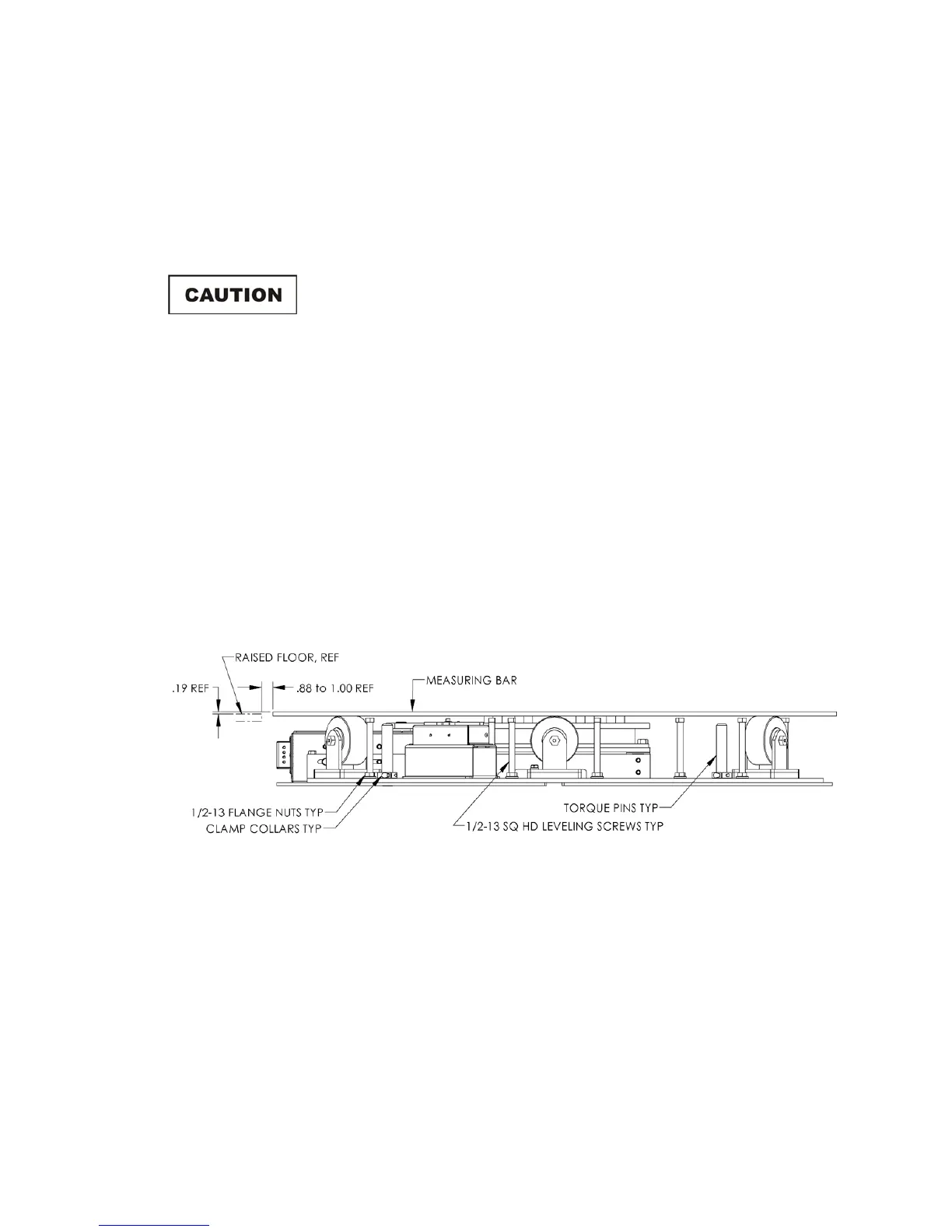

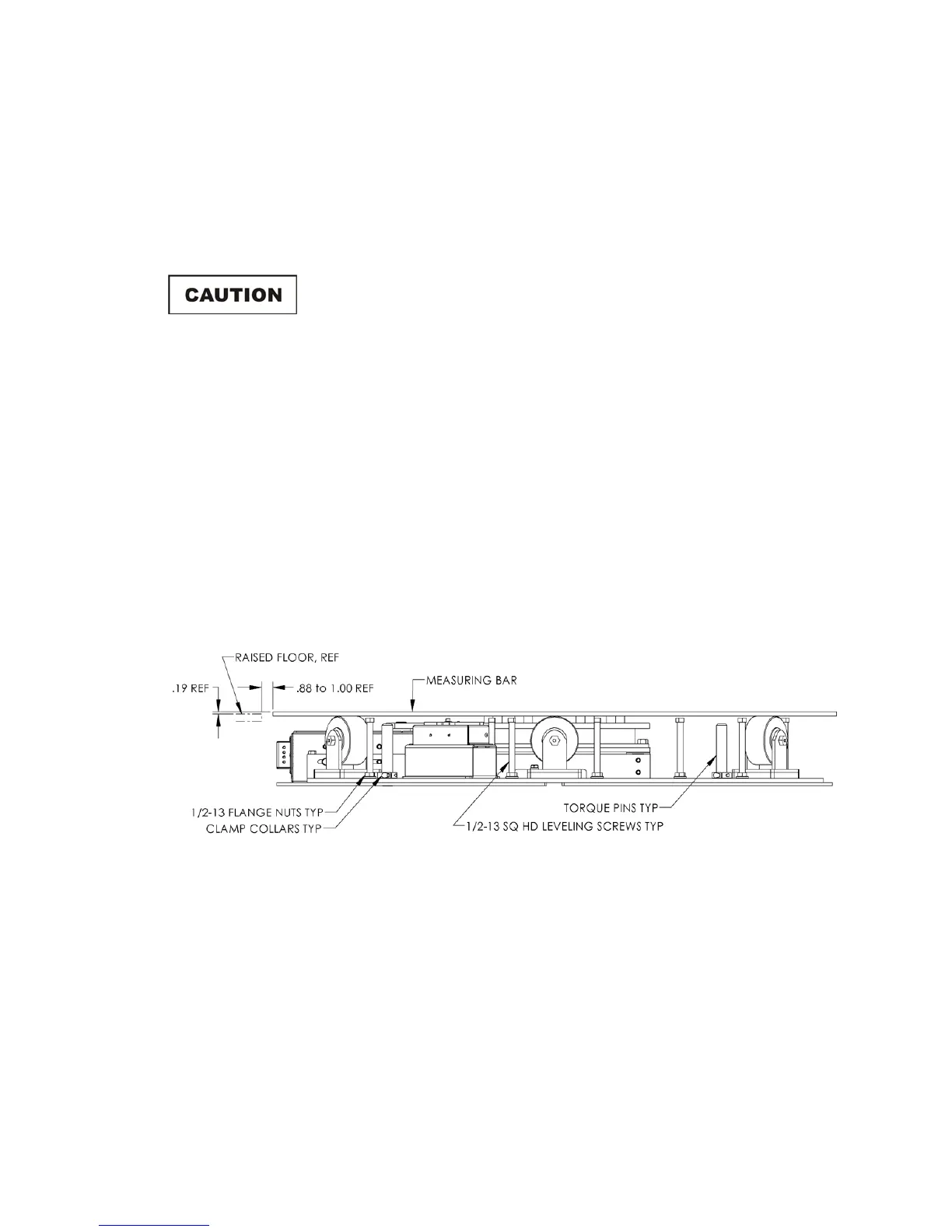

Before leveling, make sure all 1/2–13 flange nuts and clamp

collars are backed off completely to avoid pulling plates off the

floor.

14. Raise the turntable by turning the 1/2–13 square head screws clockwise

until the measuring bar top is 3/16 in above the raised floor; this is just a

rough finished height. Check the height with a leveling instrument.

When the turntable is leveled, tighten flange nuts on the square head

screws and secure set collars on the torque pins down onto the base top

surface and outer plate, if applicable. Remove the measuring bar. See

the Elevation View illustration in the next section and the drawings

located in the back pocket of this manual.

FLOOR FLANGE INSTALLATION IN A PANELED FLOOR

Elevation View

The ground ring assembly includes a floor flange with a mounted brush ring that

interfaces with the contact ring mounted beneath the turntable top. The floor

flange provides constant electrical contact with the ground plane.

Mounting methods vary according to user specifications. Clearance holes are

provided at evenly-spaced intervals along the outside perimeter of the

floor flange to attach to a customer supplied ground plane. These instructions

describe installation for a paneled floor. For concrete pit mounting instructions

see Floor Flange Installation in Concrete Pit on page 26.

Loading...

Loading...