Mini8™ CONTROLLER

INSTALLATION AND WIRING INSTRUCTIONS

HA028497/7 (CN27932)

Installation Category And Pollution Degree

This unit has been designed to conform to BS EN61010 installation category II

and pollution degree 2. These are defined as follows:

Installation category II. The rated impulse voltage for equipment on

nominal 230V ac mains is 2500V.

Pollution degree 2. Normally, only non-conductive pollution occurs.

However, occasionally a temporary conductivity caused by condensation

shall be expected.

Personnel

Installation MUST be carried out only by qualified personnel.

Enclosure Of Live Parts

To prevent hands or metal tools touching parts that may be electrically live,

the unit must be installed in an enclosure.

Wiring

It is important to connect the unit in accordance with the data on this

sheet, ensuring the protective Earth connection is ALWAYS fitted first and

disconnected last. Wiring MUST comply with local wiring regulations, e.g. in

the UK, the latest IEE wiring regulations (BS7671), or for the USA, NEC Class

1 wiring methods. Use only copper conductors for connections. Terminal

tightening torque 0.4Nm max.

Caution

Do not connect AC supply to low voltage sensor input or low level inputs and outputs.

Power Isolation

The installation must include a power isolating switch or circuit breaker.

This should be in close proximity to the unit (< 1 metre), in easy reach of the

operator and marked as the disconnecting device for the unit.

Overcurrent Protection

It is recommended that the power supply to the system be fused appropriately

to protect the cabling to the unit.

Conductive Pollution

Electrically conductive pollution, e.g. carbon dust, MUST be excluded from

the enclosure in which the unit is installed. To secure a suitable atmosphere in

conditions of conductive pollution, an air filter should be fitted to the air intake

of the enclosure. Where condensation is likely, a thermostatically controlled

heater should be included in the enclosure.

Over-temperature Protection

When designing a control system it is essential to consider the consequences

should any part of the system fail. In temperature control applications the

primary danger is the heating will remain constantly on. This could spoil the

product, but more seriously, it might damage the process machinery being

controlled, or even cause a fire.

Reasons for the heating remaining on continuously include:

1 The temperature sensor is detached from the process

2 The thermocouple wiring has short circuited

3 The unit has failed with the heating output constantly on

4 The external valve or contactor is sticking in the heating condition

5 Unit setpoint is set too high

Where damage or injury can occur, it is recommended that a separate

over-temperature protection unit, and an independent temperature sensor, to

isolate the heating circuit, be fitted.

Note Alarm relays within the unit do not indicate all failure conditions.

Installation Requirements For EMC

To comply with European EMC directive certain installation precautions are

necessary:

For general guidance, refer to EMC Installation Guide, part no. HA025464.

With relay outputs, it may be necessary to fit suitable filters to suppress

conducted emissions. Filter requirements depend on the type of load. Typical

applications may use Schaffner FN321 or FN612.

For table-top installation, if a standard power socket is to be used, compliance

with commercial and light industrial emissions standard is usually required.

To comply with conducted emissions standard, a suitable mains filter must be

installed, such as Schaffner FN321 or FN612.

INSTALLATION SAFETY REQUIREMENTS

Various symbols used on the instrument are described below:

Caution (refer to the

accompanying documents)

Protective

earth terminal

!

Functional

(ground) earth

MANUFACTURING ADDRESS

U.K. Worthing

Invensys Eurotherm Limited

Telephone: (+44 1903) 268500

Fax: (+44 1903) 265982

E-mail: info@eurotherm.co.uk

Web: www.eurotherm.co.uk

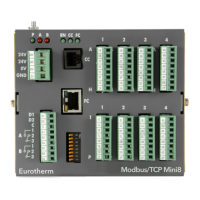

What is the Mini8 Controller?

The Mini8 Controller is a compact multi-loop PID controller

and data acquisition unit, offering a choice of I/O and field

communications and designed for mounting on a 35mm

‘Top Hat’ DIN Rail.

Pre-assembled in the factory, the controller is fitted with all

the I/O required for the application, as specified at time

of order. With standard applications the Mini8 Controller

can be supplied as a configured instrument or it can be

configured using iTools configuration software running on a

personal computer.

I/O Connection

Terminals

Power Supply

Communications

Connection Terminals

(version dependent)

Standard I/O

Connection

Terminals

Routing Of Wires

To minimise interference from electrical noise, low voltage DC connections and

sensor input wiring must be routed away from high-current power cables. If this is

not practical, use shielded cables, shield grounded at both ends, and keep cable

lengths to a minimum.

GENERAL

This unit is intended for Industrial Temperature and Process Control applications,

within the requirements of the European Directives on Safety and EMC.

Warning

The Safety and EMC protection provided can be seriously impaired, if the instru-

ment is not used in the manner specified. The installer MUST ensure the Safety and

EMC of all installations.

Unpacking And Storage

The packaging contains the unit, this sheet, and a CD. If on receipt, the packaging

or unit are damaged, do NOT install, but contact the supplier. If being stored

before use, protect from humidity and dust in an ambient temperature range of

-30ºC to +75ºC.

Caution: Electrostatic discharge

Always observe all electrostatic precautions, before handling the unit.

Service And Repair

The unit has no servicable parts. Contact the supplier for repair.

Cleaning

Isopropyl Alcohol may be used to clean the labels. (Labels will become illegible

if water or water based products are used.) A mild soap solution can be used to

clean other exterior surfaces.

RoHS statement

© Copyright Eurotherm Limited™ 2010

All rights are strictly reserved. No part of this document may be reproduced, modified, or

transmitted in any form by any means, nor may it be stored in a retrieval system other than for

the purpose to act as an aid in operating the equipment to which the document relates, without

the prior written permission of Eurotherm Limited.

Eurotherm Limited pursues a policy of continuous development and product improvement.

The specification in this document may therefore change without notice. The information in

this document is given in good faith, but is intended for guidance only. Eurotherm Limited will

accept no responsibility for any loses arising from errors in this document.

COMMUNICATIONS

Communications connection

terminals are version dependent;

see overleaf for details.

RT4 - 2, 3, 4 Wire RTD Input

ISOLATION

Channel to Channel: 42V pk.

Channel to system: 42V pk.

Legend Function

A ..... CH1 I+

B ..... CH1 S+

C ..... CH1 S-

D ..... CH1 I-

E ..... CH2 I+

F . . . . . CH2 S+

G ..... CH2 S-

H ..... CH2 I-

I . . . . . CH3 I+

J . . . . . CH3 S+

K ..... CH3 S-

L . . . . . CH3 I-

M ..... CH4 I+

N ..... CH4 S+

O ..... CH4 S-

P . . . . . CH4 I-

Wire

Connections

2 3 4

Legend Function

A ..... TC1+

B ..... TC1-

C ..... TC2+

D ..... TC2-

E ..... TC3+

F . . . . . TC3-

G ..... TC4+

H ..... TC4-

I . . . . . TC5+

J . . . . . TC5-

K ..... TC6+

L . . . . . TC6-

M ..... TC7+

N ..... TC7-

O ..... TC8+

P . . . . . TC8-

TC8/TC4

-Thermocouple Input

Note.

TC4 supports Channels 1

to 4 only.

ISOLATION

Channel to Channel: 42V

pk.

Channel to system: 42V pk.

Legend Function

A ..... N/A

B ..... N/A

C ..... N/A

D ..... N/A

E ..... N/A

F . . . . . N/A

G ..... N/A

H ..... N/A

I . . . . . In1 A

J . . . . . In1 B

K ..... No connection

L . . . . . In2 A

M ..... In2 B

N ..... No connection

O ..... In3 A

P . . . . . In3 B

CT3 - Current

Transformer Input

ISOLATION

Channel to Channel - N/A

Channel to system - N/A

Note. Isolation provided by

current transformers.

DO8 - Logic Output

Note. Requires 24Vdc supply.

ISOLATION

Channel to Channel - N/A

Channel to system: 42V peak

with independant supply

Note. * - Linked internally.

Legend Function

A ..... Supply In +

B ..... Supply In +

C ..... OP1 +

D ..... OP2 +

E ..... OP3 +

F . . . . . OP4 +

G ..... Supply & OP-

H ..... Supply & OP-

I . . . . . Supply In +

J . . . . . Supply In +

K ..... OP5 +

L . . . . . OP6 +

M ..... OP7 +

N ..... OP8 +

O ..... Supply & OP-

P . . . . . Supply & OP-

RL8 - Relay Output

(slots 2 and/or 3 only)

Contact voltage/current - 264Vac/2A

RMS max.

ISOLATION (264VAC BASIC)

Channel to Channel - 264Vac basic

Channel to system - Reinforced

Note. Protective earth conductor MUST

be used if RL8 module is fitted.

Legend Function

A ..... RLY1 A

B ..... RLY1 B

C ..... RLY2 A

D ..... RLY2 B

E ..... RLY3 A

F . . . . . RLY3 B

G ..... RLY4 A

H ..... RLY4 B

I . . . . . RLY5 A

J . . . . . RLY5 B

K ..... RLY6 A

L . . . . . RLY6 B

M ..... RLY7 A

N ..... RLY7 B

O ..... RLY8 A

P . . . . . RLY8 B

DI8 - Logic Input

Note. Input specification

as for ‘Standard I/O’

above.

ISOLATION

Channel to channel: 42V pk.

Channel to system: 42V pk.

Legend Function

A ..... D1+

B ..... D1-

C ..... D2+

D ..... D2-

E ..... D3+

F . . . . . D3-

G ..... D4+

H ..... D4-

I . . . . . D5+

J . . . . . D5-

K ..... D6+

L . . . . . D6-

M ..... D7+

N ..... D7-

O ..... D8+

P . . . . . D8-

*

*

Legend Function

A ..... OP1+

B ..... OP1-

C ..... OP2+

D ..... OP2-

E ..... OP3+

F . . . . . OP3-

G ..... OP4+

H ..... OP4-

I . . . . . OP5+

J . . . . . OP5-

K ..... OP6+

L . . . . . OP6-

M ..... OP7+

N ..... OP7-

O ..... OP8+

P . . . . . OP8-

AO8/AO4 - Analog

Output (slot 4 only)

Output current - 0 to 20mA,

360 ohm max load.

Note. AO4 supports Channels 1

to 4 only

ISOLATION

Channel to Channel: 42V pk.

Channel to system: 42V pk.

Caution

The Mini8 Controller is intended for operation at safe low voltage levels, except the Relay

Module. Voltages in excess of 42V dc must NOT be applied to any terminals other than the

Relay Module, RL8.

A protective Earth connection is required. ALWAYS ensure that the protective Earth is fit-

ted first and disconnected last.

Do NOT replace the battery. Return the unit to the factory if replacement is required.

Legend Function

D1 . . . . . . . . . . Digital Input 1

D2 . . . . . . . . . . Digital Input 2

C ...........Digital Input Common

A1 . . . . . . . . . . Relay A n/open

A2 . . . . . . . . . . Relay A n/closed

A3 . . . . . . . . . . Relay A Common

B1 . . . . . . . . . . Relay B n/open

B2 . . . . . . . . . . Relay B n/closed

B3 . . . . . . . . . . Relay B Common

Note: Digital Inputs:

-28.8V to +5V = Off

+5V to +10.8V = undefined

+10.8V to +28.8V = On

Typ. drive current: 2.5mA

@10.8V

Relay Contacts:

1 Amp max, 42V dc max.

Power Supply

This terminal can accept wire sizes 0.2 - 2.5mm (24 - 12 awg).

Legend Supply

24V 24V dc

24V 24V dc

0V 0V

GND Ground

Linked

POWER SUPPLY SPECIFICATION

Power supply voltage: 17.8Vdc min to 28.8Vdc max

Power comsumption: 15W max

Standard I/O Connections

Communications Interface Leds

!

LEDs

Legend Colour Function Action

P Green Indicates Power status On - Power On

Off - Power Off

A Red Indicates Relay A state On - Energised

Off - De-Energised

B Red Indicates Relay B state On - Energised

Off - De-Energised

Leg. Col. Function Action

RN Green Run mode On - Running

Blinking - Standby/Config

Off - Not Running

CC Green Configuration activity On - N/A

Blinking - Config Traffic

Off - N/A

FC Green Field Comms activity On - Connected

Blinking - Ready

Off - Offline

Off - No traffic or offline

Blinking - Comms Traffic

NET Bi-Col Network Status Off - Offline

(Enhanced DeviceNet Only) Blinking Green - Online but no connections

On Green - Online with connections

Blinking Red - Connection timed out

On Red - Total connection failure

Blinking Red/Green - Comms fault

MOD Bi-Col Module Status Off - Power not supplied to network

(Enhanced DeviceNet Only) On Green - DeviceNet interface operational

On Red - Power not supplied to controller

or Checksum failure

Blinking Red/Off - Recoverable fault. Comms.

error between network and DeviceNet interface.

Blinking Red/Green - Power-up tests, failure

to enter cyclic states or invalid Baud rate

Non-enhanced

DeviceNet® and CANopen

Modbus, Profibus,

and Ethernet

Loading...

Loading...