45˚ Bevel Stop Adjustment

• Loosen the bevel lock handle and tilt the cutting head

completely to the left until it rests against the 45˚ stop.

• Use a set square to see if it at 45 degrees to the Rotary table

(avoid the TCT tips).

• If the saw blade is not in exact alignment adjustment is

necessary.

• Return the cutting head to its upright position.

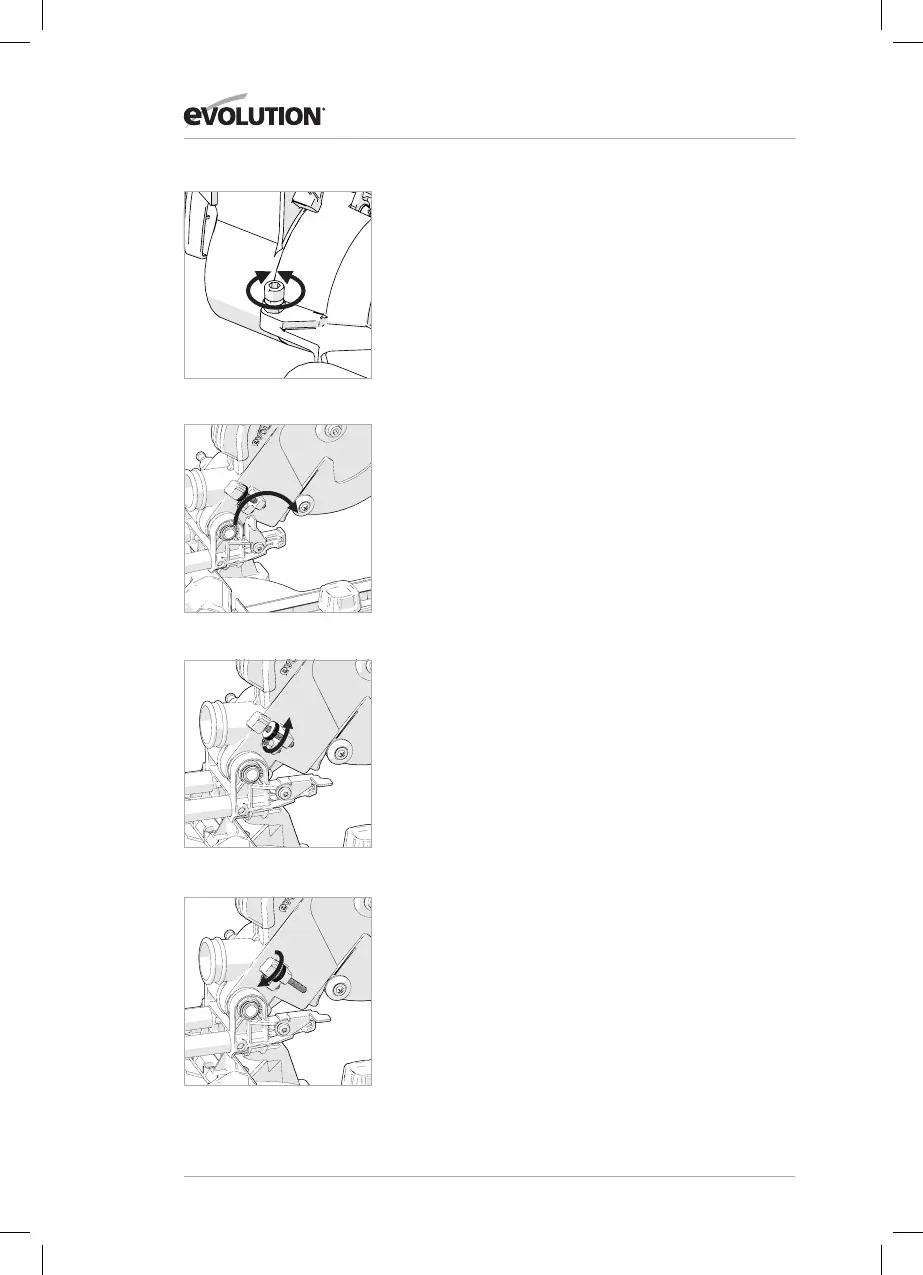

• Loosen the locknut on the 45˚ Bevel adjustment screw.

• Use a Hex Key to adjust the adjustment screw in or out as

required. (Fig. 25)

• Tilt the cutting head to the 45˚ setting and recheck for

alignment with the set square. Repeat the above steps until

the correct angular alignment is achieved.

• Tighten the adjustment screw locknut securely once

alignment is achieved.

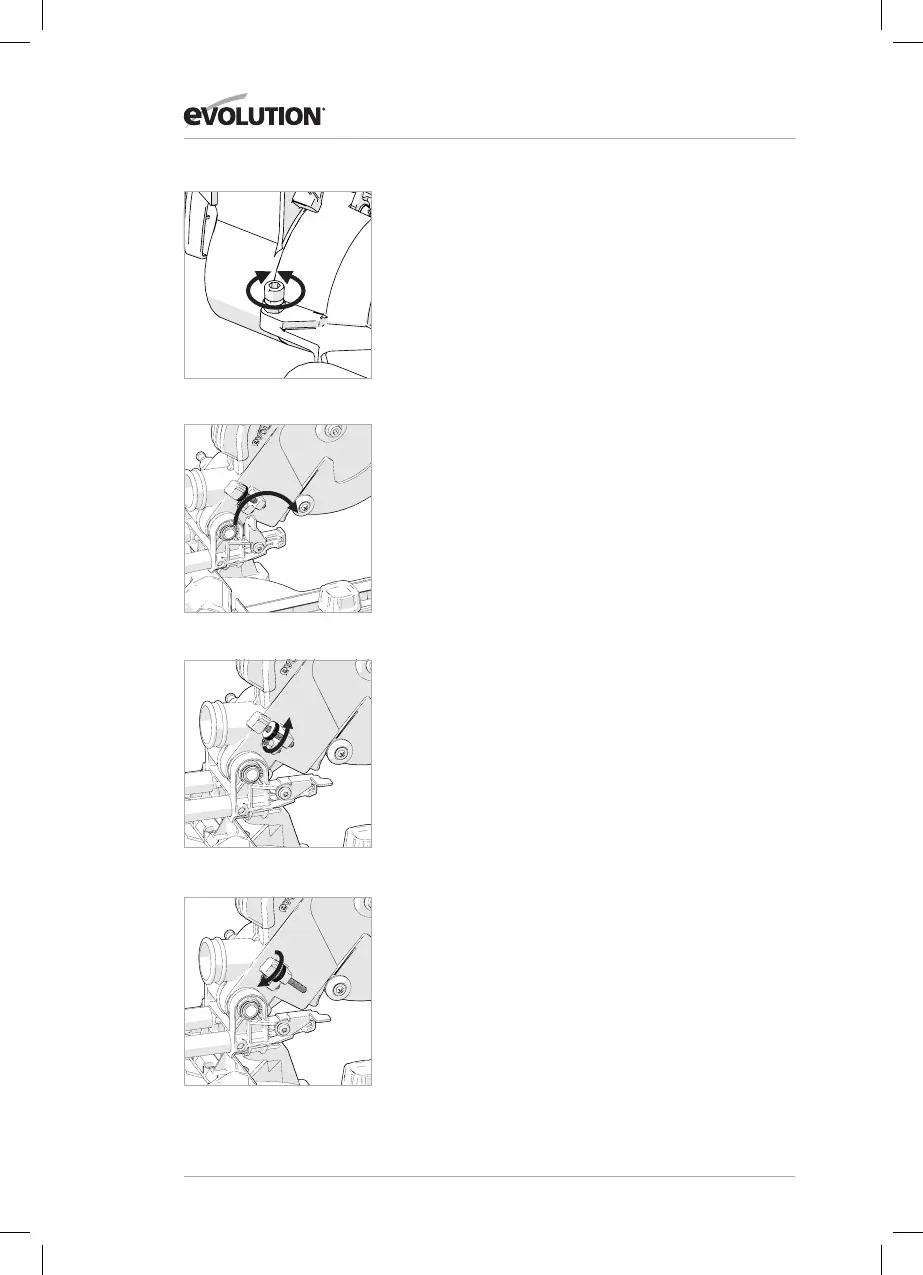

THE DEPTH STOP (Fig. 26)

Use of the depth stop allows the operator to cut slots in a

work-piece. The downward travel of the cutting head can

be limited so that the saw blade does not completely cut

through the work-piece.

Note: When using the depth stop it is advisable that the

depth of cut is checked using a scrap piece of timber to

ensure that the slot is cut correctly. By making a cut in the

work-piece, and then repeating the cut but with the work-

piece slightly repositioned to the left or right, it is possible to

perform trenching cuts.

To use the depth stop:

• Deploy the depth stop ‘stop plate’ (Fig. 26a) by rotating it

forward from its storage position alongside the machine

through approximately 150 degrees to its service position.

• Loosen the knurled locking nut. (Fig. 26b)

• Adjust the thumb - screw (Fig. 26c) to limit the cutting

heads travel to the required depth.

• Once set to the desired depth, tighten the knurled locking

nut (Fig.26b) against the retaining bracket to lock the

depth stop and ensure that there is no movement.

• When cutting is complete either re-adjust the depth stop

or return the ‘stop plate’ to its storage position.

• Check that the cutting head can be locked in the down

position by the head latching pin.

Fig. 25

Fig. 26a

Fig. 26b

Fig. 26c

20

www.evolutionpowertools.com

Loading...

Loading...