CHECKING AND SETTING OF BEVEL ANGLES

WARNING: Before making any adjustments ensure that the

machine is disconnected from the power supply.

Note: While all angular settings have been factory set, checking

and adjustment may be required as a consequence of normal

operational wear and tear.

Note: To check and adjust the Bevel Angles the machine must be

in Mitre Saw configuration.

0˚ BEVEL ANGLE

At 0˚ Bevel Angle the blade should be perpendicular and at

exactly 90˚ to the Rotary Table. An accurate engineers square

(not supplied) is needed to check the 0˚ Bevel Angle.

To check:

• Ensure that the Cutting Head is in the vertical position, against its

stop with the Bevel Pointer indicating 0˚ Bevel Angle.

• Tighten the Bevel Lock Handle.

• Lower the Cutting Head to its lowest position. The Retractable

Lower Blade Guard will rotate up into the machine.

• The engineers square can now be used to check the angle

between the blade and the Rotary Table.

If adjustment is required:

Note: The Cutting Head will need to be tilted to gain access to

the 0˚ Bevel Stop Adjustment Screw.

• Loosen slightly the 0˚ Bevel Stop Adjustment Screw locknut.

(Fig. 31)

• Use an Allen Key to turn the Bevel Stop Screw clockwise or

counterclockwise as required.

• When exact alignment between the

blade and Rotary Table is achieved, tighten the locknut.

45˚ BEVEL ANGLE

The 45˚ Bevel Angle can be checked in a similar manner to the

0˚ Bevel Angle. An accurate 45˚ Engineers Set Square

(not supplied) will be required.

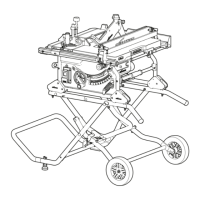

Fig. 31

Loading...

Loading...