Maintenance

Important:DoNotlubricatechainswith

penetratingoilorsolvents.Useoilorchain

lubricant.

1.Stopengine,waitforallmovingpartstostop.

2.Disconnectthewirefromthesparkplug.

3.Liftthefrontoftheunitandsupportusingjack

standsorequivalentsupport.

4.Rotatethefrontwheelsandapplyoilorchain

lubricantontothelinksofthelowerchainspans.

5.Checktheconditionofthechains(seeCheck

ConditionOfFrontDriveChainssection).

LubricateGreaseFittings

Note:Seechartforserviceintervals.

1.Stopengine,waitforallmovingpartstostop.

2.Disconnectthewirefromthesparkplug.

3.LubricatettingswithNGLIgrade#2

multi-purposegungrease.

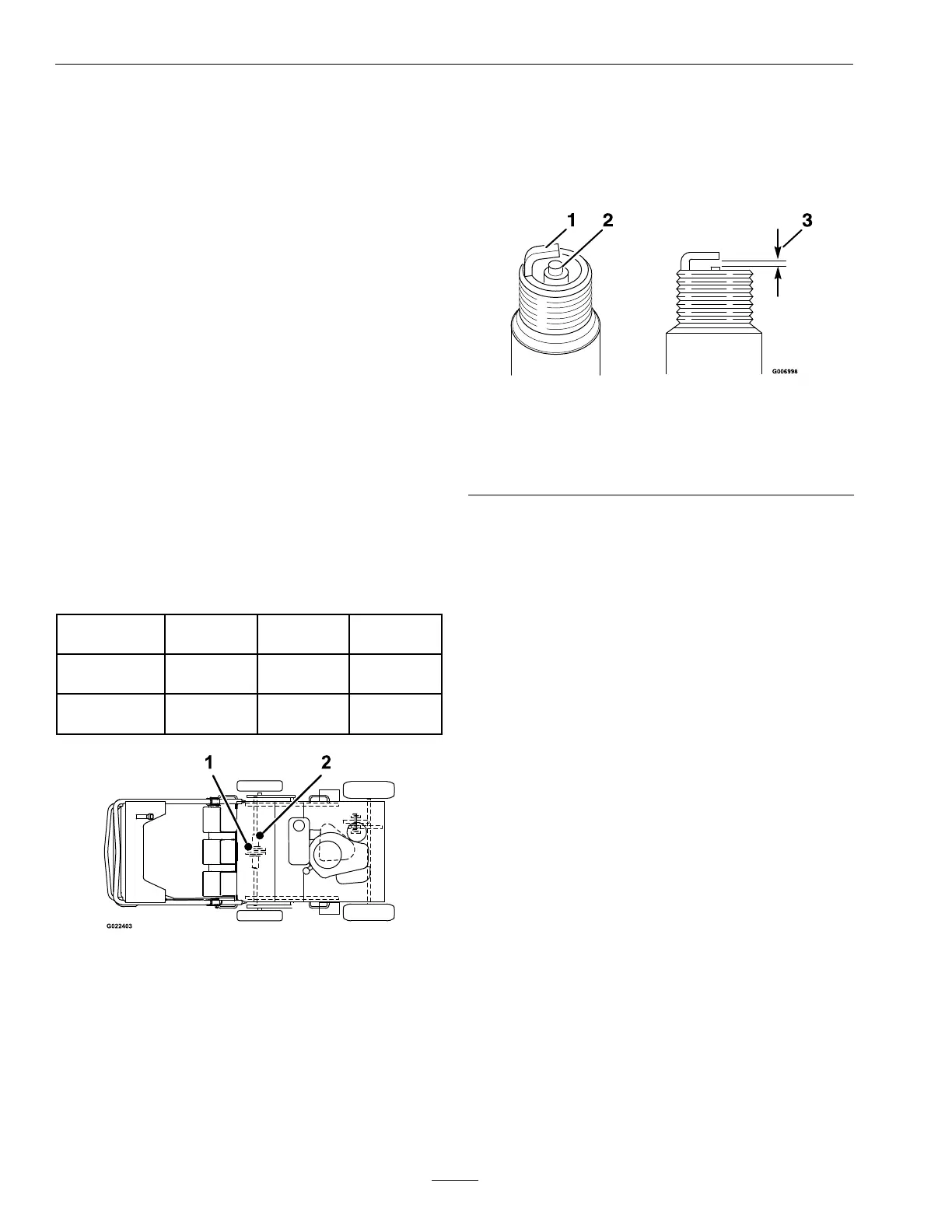

Refertothefollowingchartforttinglocations

andlubricationschedule.

LubricationChart

Fitting

Locations

InitialPumpsNumberof

Places

Service

Interval

1.TineShaft

Bearings

12

25hours

2.TineAssembly

Idlers

1-22

25hours

CheckSparkPlugs

ServiceInterval:Every100hours

1.Stoptheengineandwaitforallmovingpartsto

stop.

2.Disconnectthewirefromthesparkplug.

3.Cleanaroundthesparkplug.

4.Removethesparkplugfromthecylinderhead.

Note:Replaceacracked,fouled,ordirtyspark

plug.DoNotcleantheelectrodesbecausegrit

enteringthecylindercandamagetheengine.

5.Setthegapontheplugto0.030inch(0.76mm)

(Figure10).

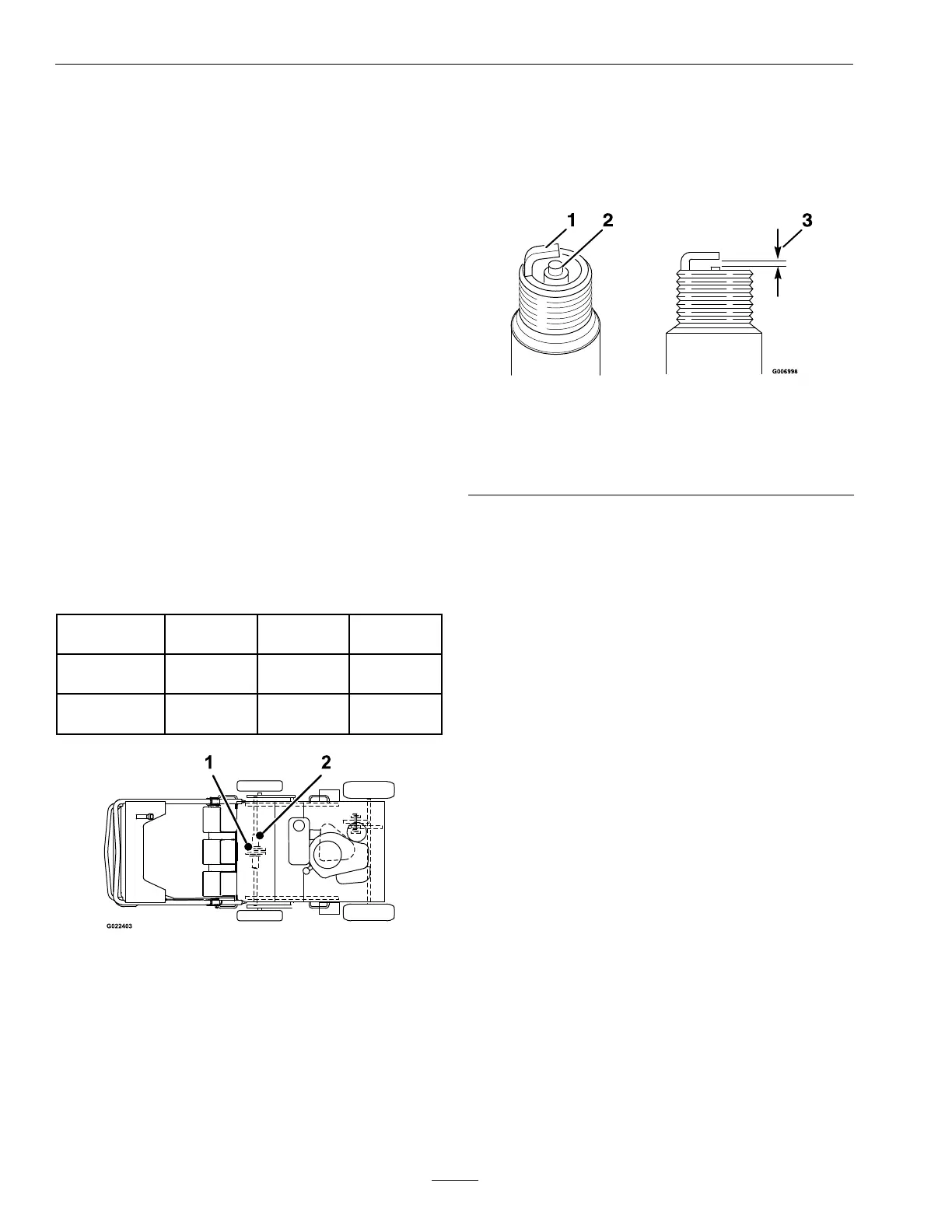

Figure10

1.Sideelectrode

3.Airgap—0.030inch

(0.76mm)

2.Centerelectrode

insulator

6.Installthesparkplugandthegasketseal.

7.Torquetheplugto17ft-lb(23N-m).

8.Connectthewiretothesparkplug.

EmptyingtheFuelTankand

CleaningtheFuelFilter

ServiceInterval:Every100hours

Thefuellter(screen)elementislocatedinsidethe

fueltank.

1.Stoptheengineandwaitforittocooldown.

Note:Draingasolineforacoldengineonly.

2.Disconnectthewirefromthesparkplug.

3.Closethefuelvalve.

4.Disconnectthefuellinebylooseningthetube

clampatthecarburetor.

5.Openthefuelvalvebyturningthelevertothe

openposition.

6.Drainthegasolinecompletelyfromthetankand

fuellineintoanapprovedfuelcontainer.

7.Removethefueltankfromthemachine.

8.Closethefuelvalve.

9.Pourasmallamountoffuelinthefueltank,move

thefuelaroundinthetank,andpouritoutinto

anapprovedfuelcontainer.

10.Installthefueltankandfuelline.

22

Loading...

Loading...