Maintenance

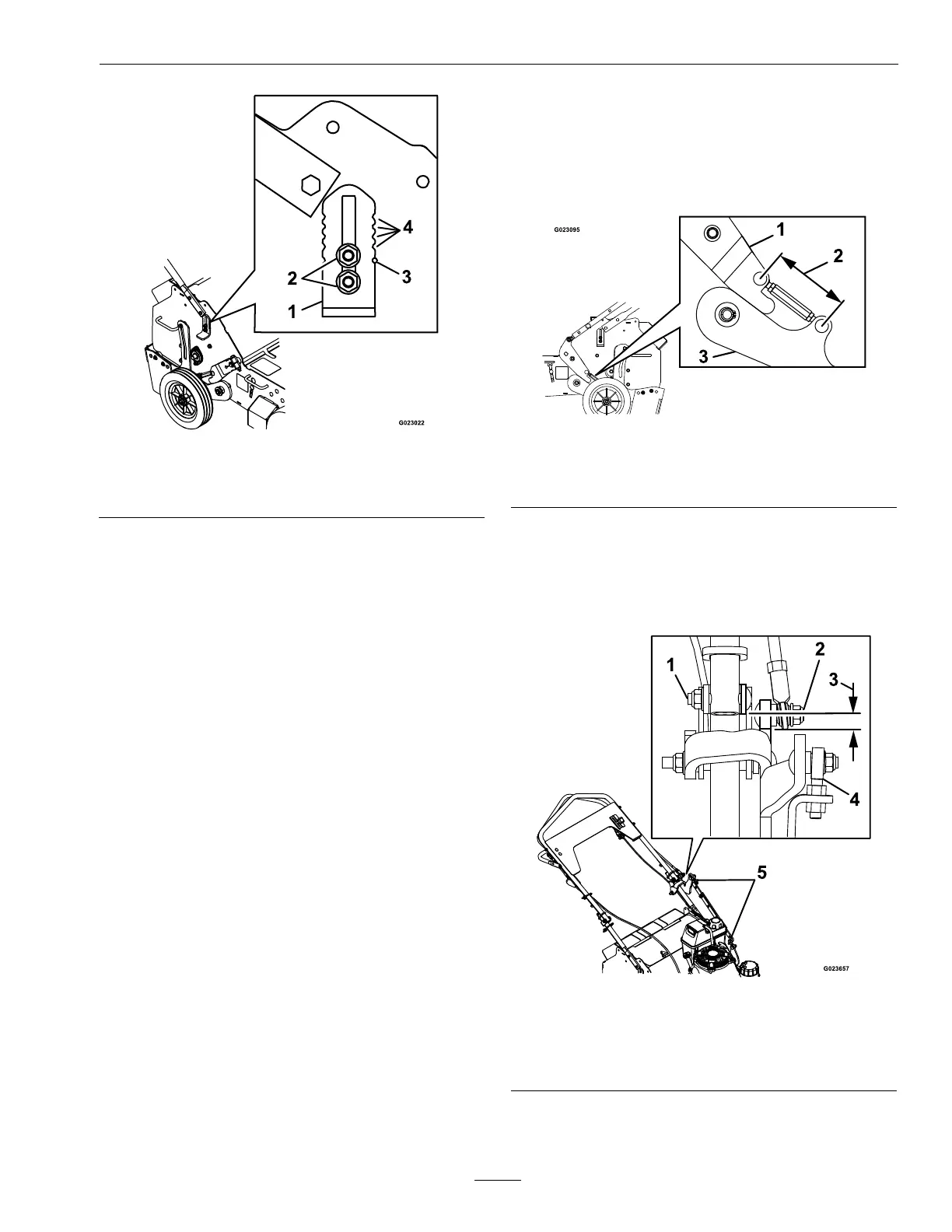

Figure14

1.Wheelstop3.Indicatorhole

2.Nuts4.Indicatornotches

4.Lowerthewheelstoptoreducethedepth.Raise

ittoincreasethecoringdepthandasrequired.

Note:Toensurethatthetinespenetratefully

intothesoil,weightscanbeaddedtotheback

ofthemachine.Themachinehasthreeweight

pocketsthatholdtheweights.Whenplacing

weight,ensurethattheloadisbalanced;ifusing

onlyoneweight,placeitinthecenterpocketand

ifusingtwo,placetheminthesidepockets.

Note:Theremovableweightsareheavy.Use

carewhenliftingthem.Makesurethatyoucan

holdthemsecurelybeforeliftingthem.Use

cautionwhenpositioningyourhandssothatyou

DoNotsetthemdownonyourhandsorngers.

5.Tightenthenutssecurelytolockthewheelstop

inplace.

6.Repeatsteps3through5forthewheelstop

ontheleftsideofthemachine.Usethevisual

indicatornotchesinthewheelstopandindicator

holesintheframetosetthewheelstopstothe

sameheightoneachside(seeFigure14).

AdjustingtheTineGround

EngagementLever

1.Stopengine,waitforallmovingpartstostop.

2.Disconnectthewirefromthesparkplug.

3.Raisethetinestothetransportposition.

4.Thewheelarmandthepivotshaftassembly

shouldhavesurface-to-surfacecontact.Ifnot,

checkthedistanceofthelowerliftlinkageand

adjustifnecessary.

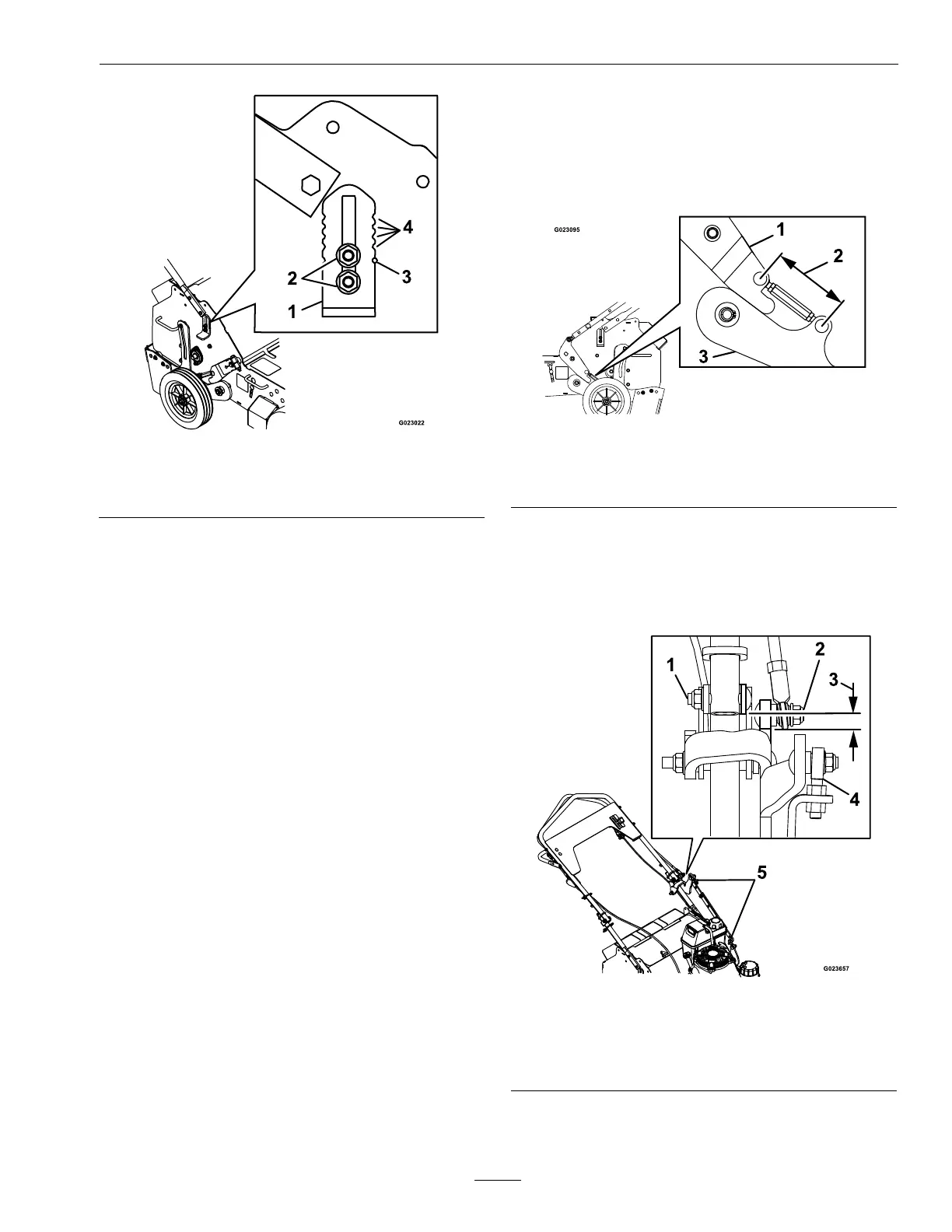

Figure15

1.Pivotshaftassembly

3.Wheelarmassembly

2.4.8inches(12cm)

5.Thelowerballjointbolt,ontheupperlinkrod,

shouldbeoffset1/4inch(6mm)fromthehandle

pivotbolt.Ifnot,loosenthelocknutsonthe

liftlinkstrapballjoints,adjustasnecessary,and

retightenlocknuts.

Figure16

1.Handlepivotbolt

4.Liftlinkstrapballjoint

2.Lowerballjointbolt5.Adjusthere

3.1/4inch(6mm)

6.Slidetheovallockingringsupwardonthehandle

andfoldthehandletowardstheengine.

27

Loading...

Loading...